Nano (ti,m)c solid solution whiskers and preparation method thereof

A solid solution and nanotechnology, applied in self-solid, chemical instruments and methods, single crystal growth, etc., can solve problems such as poor interface bonding, and achieve the effect of solving poor interface bonding, low price, and less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The method for preparing nano (Ti, M)C solid solution whiskers of the present invention includes the following steps:

[0030] (1) Raw material allocation

[0031] The raw materials for the preparation of nano-(Ti, M)C solid solution whiskers include (Ti, M)C component precursors, halogenating agents and catalysts required for the whisker synthesis reaction; wherein the component Ti precursor raw materials are metatitanic acid The precursor material of component C is glucose; the precursor material of component M is a soluble salt of at least one metal element among W, Mo, V, Cr, Ta, and Nb; the halogenating agent is sodium chloride , Potassium chloride, calcium chloride, barium chloride, lithium chloride, or any two mixtures. The catalyst is one of soluble nickel salt, soluble cobalt salt and soluble iron salt.

[0032] The quality of the precursor raw materials of the components Ti, C, and M is calculated and weighed according to the weight percentage of Ti, M and C in cla...

Embodiment 1

[0040] Dissolve 19.2g of metatitanic acid, 5.02g of ammonium metatungstate, 18.94g of glucose, 4.79g of sodium chloride and 2.05g of cobalt chloride in 250ml of distilled water and stir to obtain a precursor solution; 2) Combine the precursors The solution was placed in a blast drying oven and dried at 60°C for 5 hours to obtain a fluffy precursor mixture; 3) The precursor mixture was placed in a tube furnace, under Ar gas protection, at 1100°C Carbothermic reaction was carried out after holding for 4h to obtain unpurified nano-(Ti, 40W)C whiskers; 4) The unpurified nano-(Ti, 40W)C whiskers were burnt in the air at 400℃ for 4h to decarburize, and then passed Washing, centrifugation to separate and remove the particulate residue, and finally drying to obtain nano-(Ti, 40W)C whiskers with a whisker diameter of less than 100nm.

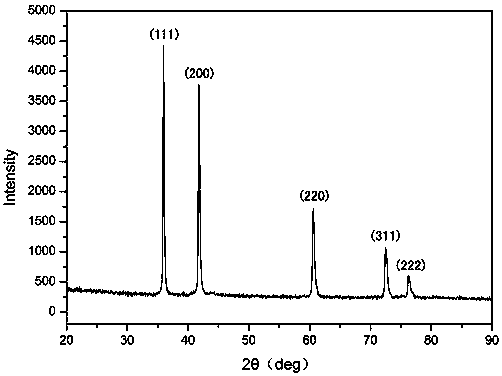

[0041] figure 1 This is the XRD pattern of the (Ti, 40W)C whisker prepared in Example 1. The prior art shows that in the range of 20-90°, pure TiC has typ...

Embodiment 2

[0044] Dissolve 18.4g of metatitanic acid, 0.13g of ammonium metavanadate, 14.92g of glucose, 9.17g of potassium chloride and 7.38g of nickel chloride in 250ml of distilled water, and stir to obtain a precursor solution; 2) Combine the precursors The solution was placed in a blast drying box and dried at 80°C for 4 hours to obtain a fluffy precursor mixture; 3) The precursor mixture was placed in a carbon tube furnace, under Ar gas protection, at 1300°C Carbothermic reaction is carried out after holding for 1h to obtain unpurified nano-(Ti, 0.1V)C whiskers; 4) The unpurified nano-(Ti, 0.1V)C whiskers are burnt in the air at 350℃ for 6h to decarburize, Then the granular residues are separated and removed by washing and centrifugation, and finally dried to obtain nano-(Ti, 0.1V)C whiskers with a whisker diameter of less than 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com