Preparation method of polylactic acid/epoxy soybean oil resin alloy and product

A technology of epoxy soybean oil and polylactic acid, applied in the field of bio-based polymer materials, can solve the problems of non-thermoplastic molding, limited improvement of elongation at break, poor mechanical properties of epoxy soybean oil resin, etc. Tensile toughness, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

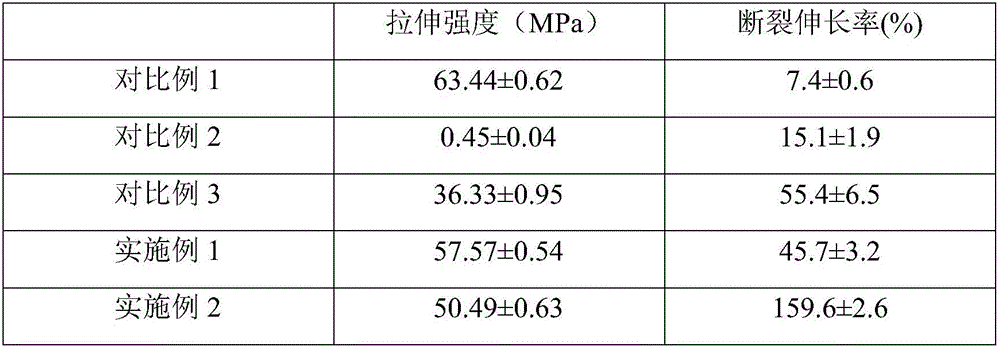

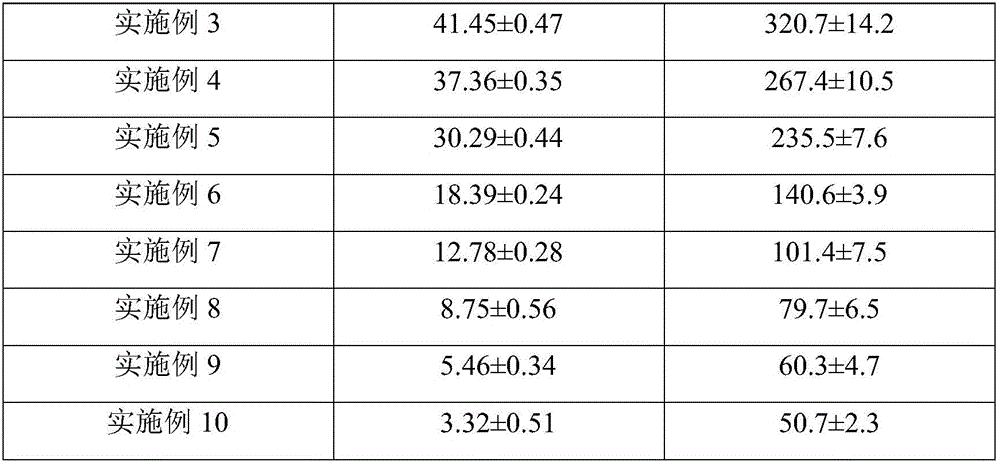

Embodiment 1

[0020] Add polylactic acid, epoxidized soybean oil, succinic acid and catalyst 4-dimethylaminopyridine into an internal mixer at 200°C, react and blend for 3 minutes, and discharge to obtain polylactic acid / epoxy soybean oleoresin alloy 1. Among them, the ratio of polylactic acid to the total mass of epoxy soybean oil and succinic acid is 19:1, the molar ratio of epoxy soybean oil to succinic acid is 1:0.5, and the content of 4-dimethylaminopyridine is polylactic acid, epoxy 0.05% of the total mass of soybean oil and succinic acid.

Embodiment 2

[0022] Add polylactic acid, epoxy soybean oil, adipic acid and catalyst 2-ethyl-4-methylimidazole into the internal mixer at 170°C, react and blend for 10 minutes, and then discharge to obtain polylactic acid / epoxy soybean oleoresin alloy 2. Wherein, the ratio of polylactic acid to the total mass of epoxy soybean oil and adipic acid is 9:1, the molar ratio of epoxy soybean oil to adipic acid is 1:0.8, and the content of 2-ethyl-4-methylimidazole is poly 0.1% of the total mass of lactic acid, epoxidized soybean oil and adipic acid.

Embodiment 3

[0024] Add polylactic acid, epoxidized soybean oil, pimelic acid and catalyst 1,8-diazabicyclo[5.4.0]undec-7-ene into an internal mixer at 180°C, react and blend for 20 minutes, and then discharge. Polylactic acid / epoxy soybean oleoresin alloy 3 was obtained. Among them, the ratio of polylactic acid to the total mass of epoxidized soybean oil and pimelic acid is 4:1, the molar ratio of epoxidized soybean oil to pimelic acid is 1:1.2, 1,8-diazabicyclo[5.4.0 ] Undec-7-ene content is 0.3% of the total mass of polylactic acid, epoxy soybean oil and pimelic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com