Carbide slag fly ash stabilized soil material for roads and preparation method thereof

A technology of calcium carbide slag and fly ash, which is applied in the field of calcium carbide slag fly ash stabilized soil materials and its preparation, can solve the problems of soil and water pollution, land occupation, and damage to the surrounding environment, and achieve simple preparation process, good strength and Water stability, choose reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

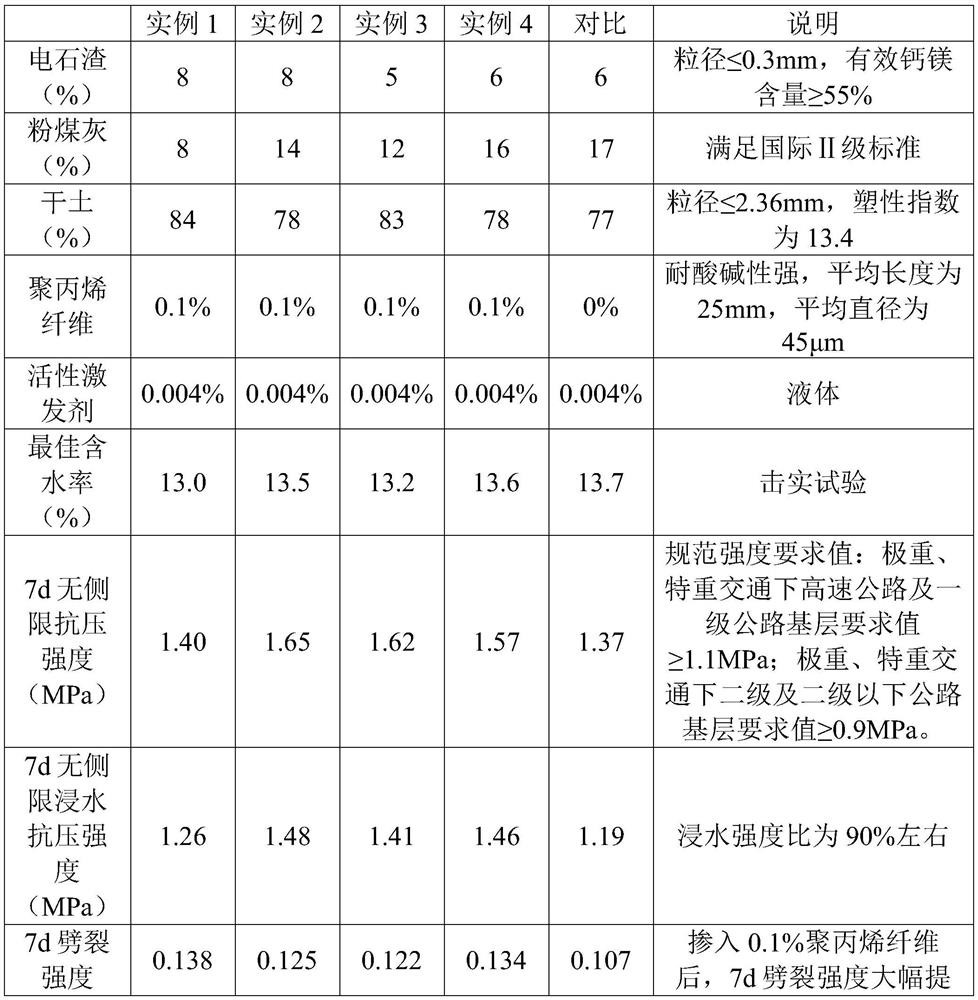

Examples

preparation example Construction

[0031] A preparation method for a calcium carbide slag fly ash stabilized soil material for roads, comprising the following steps:

[0032] Step 1. First fully mix carbide slag, fly ash and active activator, then add dispersed polypropylene fiber and mix evenly, and finally mix the mixed slag powder-fiber cement and dry soil sample evenly to obtain Mixture A ;

[0033] Step 2, sampling the mixture A to determine the optimum water content of the mixture A;

[0034] Specifically, the optimum moisture content is determined according to the compaction method in the "Test Regulations for Inorganic Binders for Highway Engineering" (JTG E51-2009).

[0035] The sample taken out is divided into 5-6 parts by quartering method, and 5-6 different water contents (with a difference of 0.5%-1.5% in turn) are added to the sample to prepare the sample. Measure the dry density of the sample under different water contents through the compaction test, draw the water content and dry density curv...

Embodiment 1

[0038] The present embodiment prepares the calcium carbide slag fly ash stabilized soil as road base, subbase filler according to the following steps:

[0039] Step 1. Sieve the pellets for the test respectively, wherein the calcium carbide slag passes through a 0.15mm sieve, the fly ash passes through a 0.075mm sieve, and the soil sample particles pass through a 2.36mm sieve, and the carbide slag, fly ash and soil sample particles are drying;

[0040] Step 2. According to mass percentage, take 8% carbide slag, 8% fly ash, 84% dry soil, 0.1% polypropylene fiber and 0.004% active activator, first fully mix the carbide slag, fly ash and active activator , then add dispersed polypropylene fibers and stir evenly, and finally mix the mixed slag powder-fiber cement with dry soil and mix evenly to obtain the mixture A;

[0041] Step 3, sample the mixture A, determine the best moisture content of the mixture A sample to be 13.0% according to the compaction method in "Highway Engineer...

Embodiment 2

[0045] The present embodiment prepares the calcium carbide slag fly ash stabilized soil as road base, subbase filler according to the following steps:

[0046] Step 1. Sieve the test materials respectively, among them, calcium carbide slag passes through a 0.15mm sieve, fly ash passes through a 0.075mm sieve, and soil sample particles pass through a 2.36mm sieve, and the carbide slag, fly ash and soil sample particles are dried ;

[0047] Step 2, according to the mass percentage, take sieved carbide slag 8%, fly ash 14%, dry soil 78%, polypropylene fiber 0.1%, active activator 0.004%, firstly carbide slag, fly ash and active excitation Mix well with the agent, then add dispersed polypropylene fibers and mix evenly, finally mix the mixed slag powder-fiber cement and dry soil evenly to obtain Mixture A;

[0048] Step 3, sample the mixture A, determine the best moisture content of the mixture A sample to be 13.6% according to the compaction method in "Highway Engineering Inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com