Preparation process of recyclable coffee residue plant fiber polypropylene particles

A plant fiber and preparation process technology is applied in the field of preparation technology of coffee grounds plant fiber polypropylene particles, and can solve the problems of not using plant fibers, complex preparation methods of polypropylene particles, poor environmental protection performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

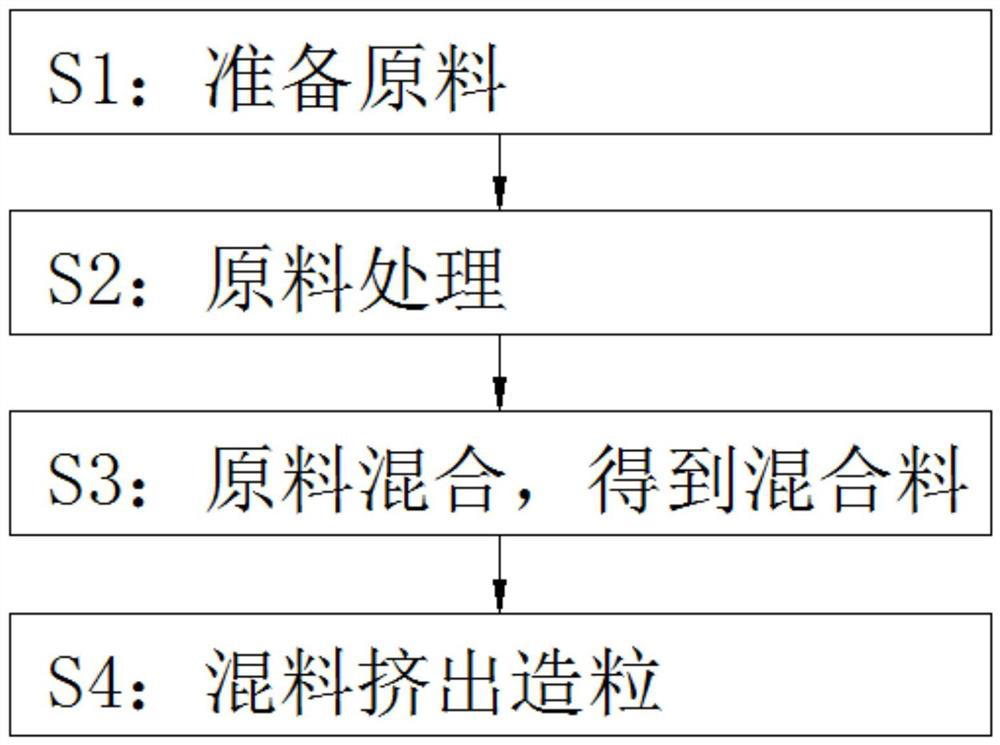

[0036] refer to figure 1 , the preparation process of recyclable coffee grounds plant fiber polypropylene particles, comprising the following preparation steps:

[0037] S1: Prepare raw materials: raw materials include 35 parts of coffee grounds powder, 60 parts of polypropylene resin, 2 parts of phase solvent, 4 parts of toughening agent component, 1 part of diffusing agent, 1 part of maleic anhydride, 0.7 parts of anti-uv agent, 3 parts of oxygen agent component, 1 part of white oil, 0.1 part of lubricant, toughening agent component includes polypropylene, expanded polystyrene, chlorinated polyethylene; antioxidant component includes phenolic toughening agent component , trinonylphenyl phosphite, polyphosphate;

[0038] S2: raw material processing: raw material crushing and screening;

[0039] S3: mixing raw materials: mixing the coffee grounds powder and polypropylene resin for the first time, and intermittently adding a phase solvent to obtain the first mixture A, and mi...

Embodiment 2

[0060] refer to figure 1, the preparation process of recyclable coffee grounds plant fiber polypropylene particles, comprising the following preparation steps:

[0061] S1: Prepare raw materials: raw materials include 38 parts of coffee grounds powder, 70 parts of polypropylene resin, 3.5 parts of phase solvent, 6 parts of toughening agent components, 2 parts of diffusing agent, 2 parts of maleic anhydride, 0.9 parts of anti-UV agent, 4.5 parts of oxygen agent components, 1.5 parts of white oil, 0.3 parts of lubricants, toughening agent components include polypropylene, expanded polystyrene, chlorinated polyethylene; antioxidant components include phenolic toughening agent components , trinonylphenyl phosphite, polyphosphate;

[0062] S2: raw material processing: raw material crushing and screening;

[0063] S3: mixing raw materials: mixing the coffee grounds powder and polypropylene resin for the first time, and intermittently adding a phase solvent to obtain the first mixt...

Embodiment 3

[0084] refer to figure 1 , the preparation process of recyclable coffee grounds plant fiber polypropylene particles, comprising the following preparation steps:

[0085] S1: Prepare raw materials: raw materials include coffee grounds powder 40kg, coffee shell 10kg, phase solvent 5kg, toughening agent component 8kg, diffusing agent 3kg, maleic anhydride 3kg, anti-uv agent 1.6kg, antioxidant component 6kg, white Oil 2kg, lubricant 0.5kg, toughener components include polypropylene, expanded polystyrene, chlorinated polyethylene; antioxidant components include phenolic toughener components, trinonylphenyl phosphite, polyphosphate;

[0086] S2: raw material processing: raw material crushing and screening;

[0087] S3: mixing raw materials: mixing the coffee grounds powder and polypropylene resin for the first time, and intermittently adding a phase solvent to obtain the first mixture A, and mixing the first mixture A with the rest of the raw materials;

[0088] S4: compounding e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com