Cable troughs used in earthquake areas and loose soil areas

A technology for loose soil and cable troughs, applied in the field of cable troughs, can solve the problems of not meeting construction requirements, low impact resistance, affecting the safety of cables or optical cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

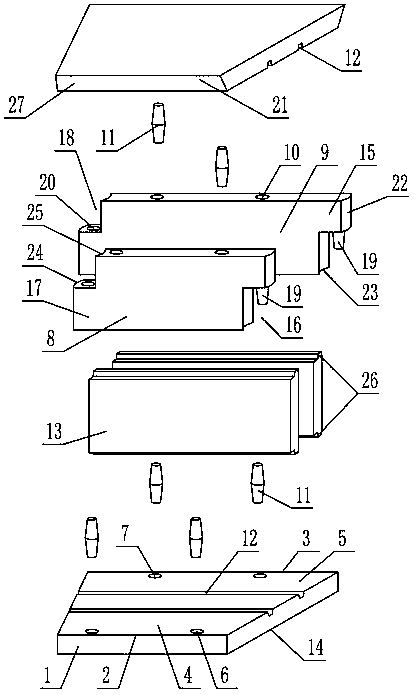

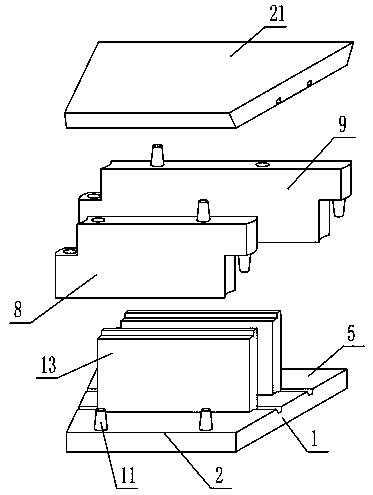

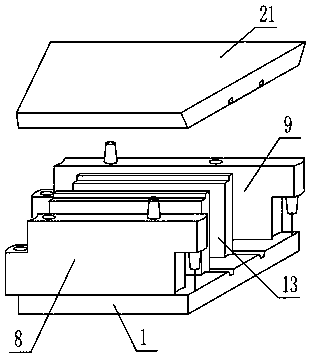

[0052] As shown in the figure, the cable trough used in the earthquake area and the loose soil area includes a bottom plate 1, and the four sides of the bottom plate 1 are isosceles trapezoids including parallel short sides 2 and long sides 3, and two equal-length waist sides 14. Two short side holes 6 are arranged on the short side part 4 close to the short side, and two long side holes 7 are arranged on the long side part 5 close to the long side on the bottom plate. and the middle line between the long sides are arranged symmetrically; when two bottom plates are butted according to the short side of one bottom plate and the long side of the other bottom plate, the two sides of the butt joint correspond to the adjacent short side holes and long side holes. The spacing is equal to the spacing between the two short-side holes on the same base plate. Columns are inserted in the short-side holes and the long-side holes. The short-side board 8 is provided on the short-side part 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com