Powder coating bonding machine

A powder coating and bonding machine technology, applied in mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve problems such as easy shutdown, affect work efficiency, viscosity enhancement, etc., and improve the powder mixing rate. , Good cooling effect and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

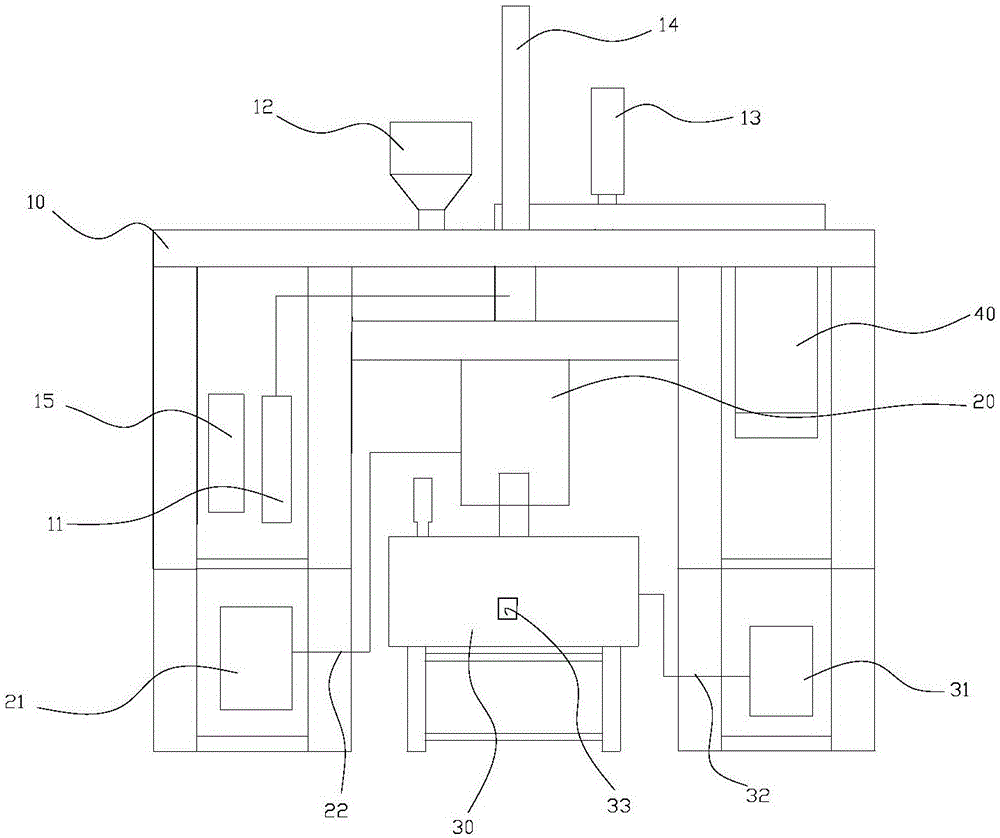

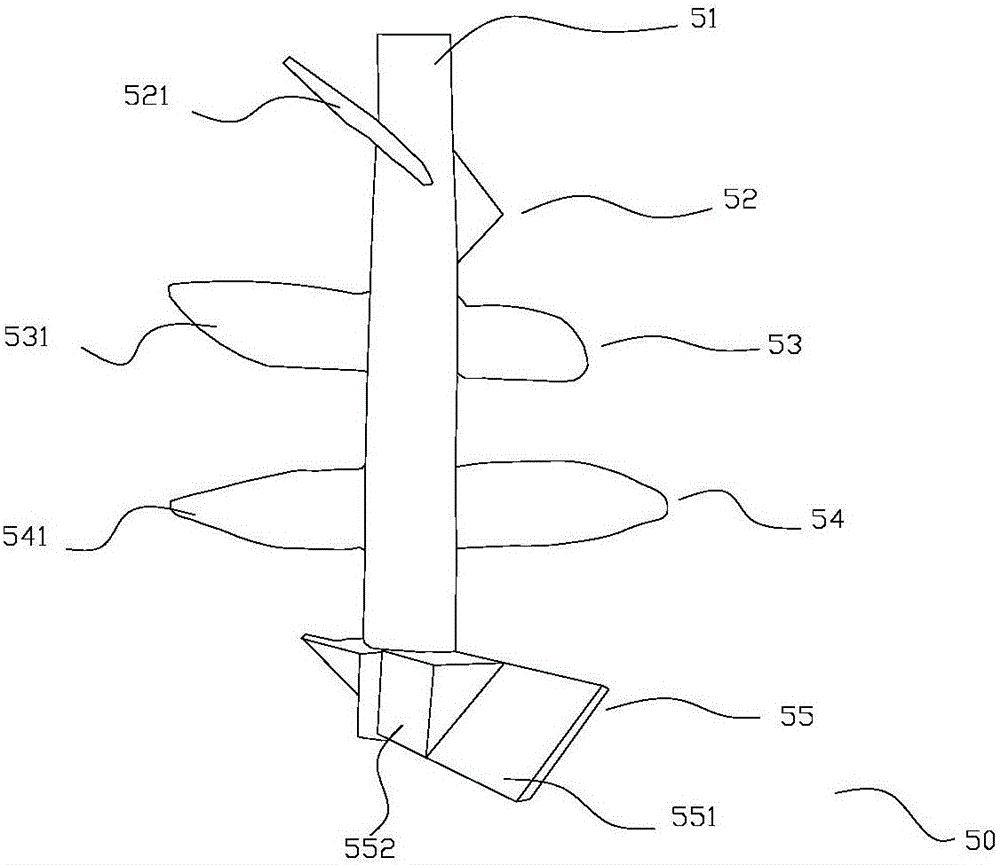

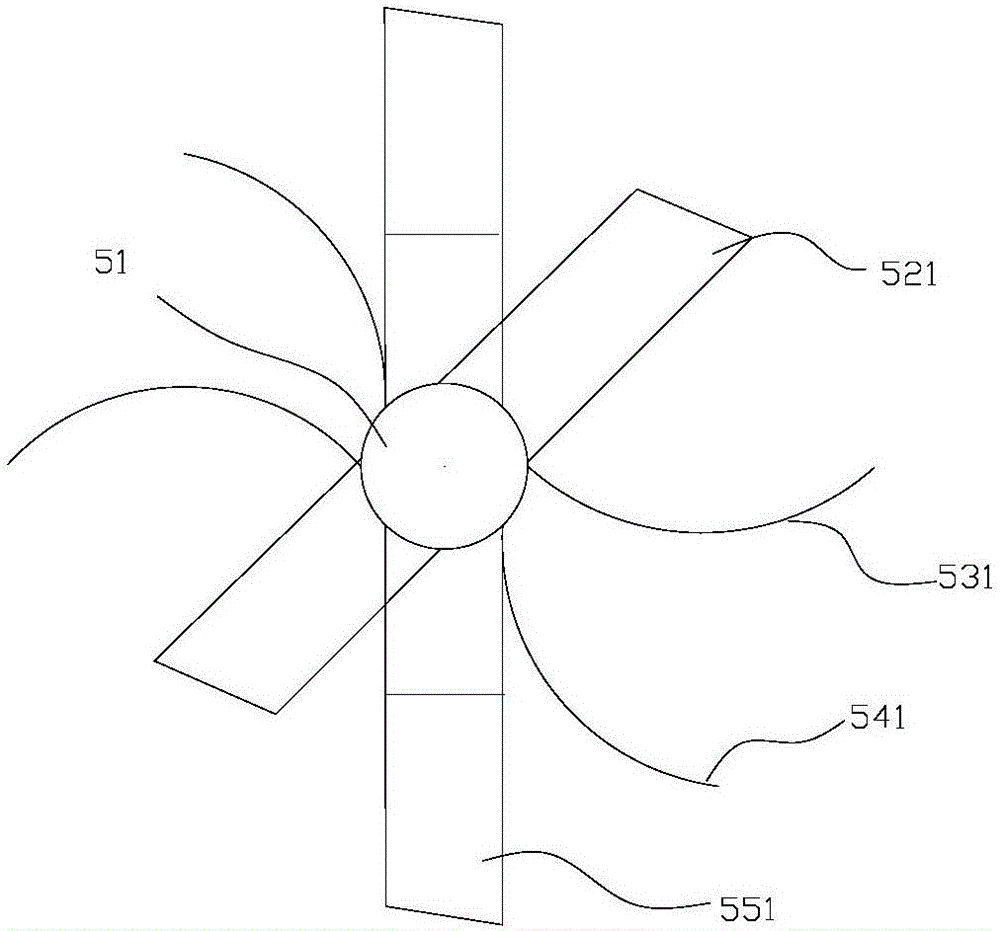

[0030] Such as Figure 1-3 As shown, a powder coating bonding machine includes a frame 10, a stirring paddle 50, a bonding cylinder 20, a lower hopper 12, a driving device 40, a nitrogen generating device 11, a first cooling device and a controller (not shown in the figure) ;

[0031] One end of the stirring paddle 50 is fixed on the frame 10, and the other end extends into the bonding cylinder 20 for stirring the powder in the bonding cylinder 20, and the driving device 40 is used to drive the stirring paddle 50 to rotate; the lower hopper 12 and the Bonding cylinder 20 is connected, and is used for adding powder in bonding cylinder 20; Nitrogen making device 11 is connected with bonding cylinder 20, is used for delivering nitrogen in bonding cylinder 20, prevents powder from being oxidized at high temperature;

[0032] The first cooling device compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com