Automatic peg welding machine

An automatic welding machine and welding head technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of long preparation time, high labor intensity, welding effect, and large influence on forming quality, etc., and achieve the degree of automation High, good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

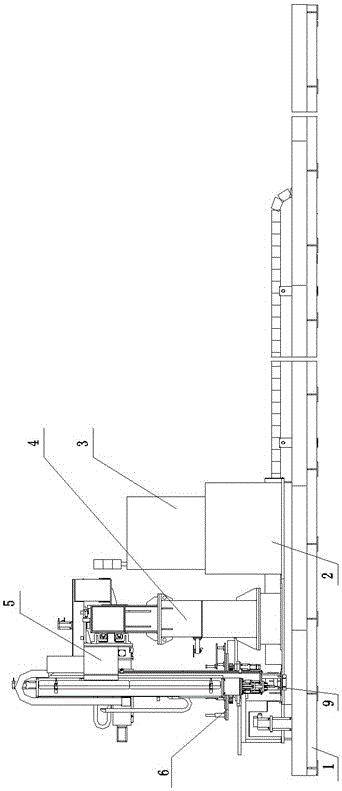

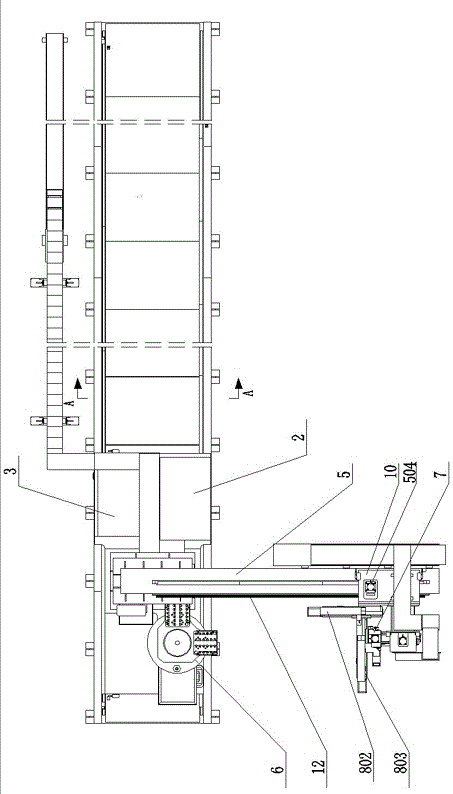

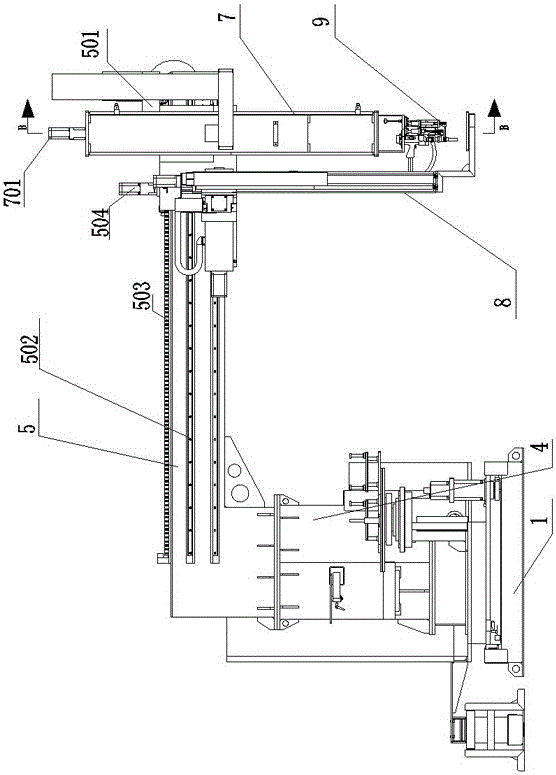

[0041] A kind of stud automatic welding machine, see attached figure 1 to attach Figure 24 , in the figure: base 1, welding power supply 2, electrical control system 3, column 4, cantilever support assembly 5, cantilever connecting frame 501, cantilever linear guide rail 502, cantilever rack 503, rotary code disc assembly 6, welding head vertical Adjust slide seat 7, automatic conveying screw assembly 8, automatic welding head assembly 9, horizontally moving slide plate 10, travel motor 11, travel gear 12, travel rack 13, bottom slide seat 14, bottom linear guide rail 15.

[0042] In the rotary code disc assembly 6, the rotary support 601, the rotary drive servo motor 602, the tapered roller bearing 603, the rotary spindle 604, the large gear 605, the sensing rod positioning seat 606, the sensing rod 607, the platform 608, the square code Disk 609, peg 610, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com