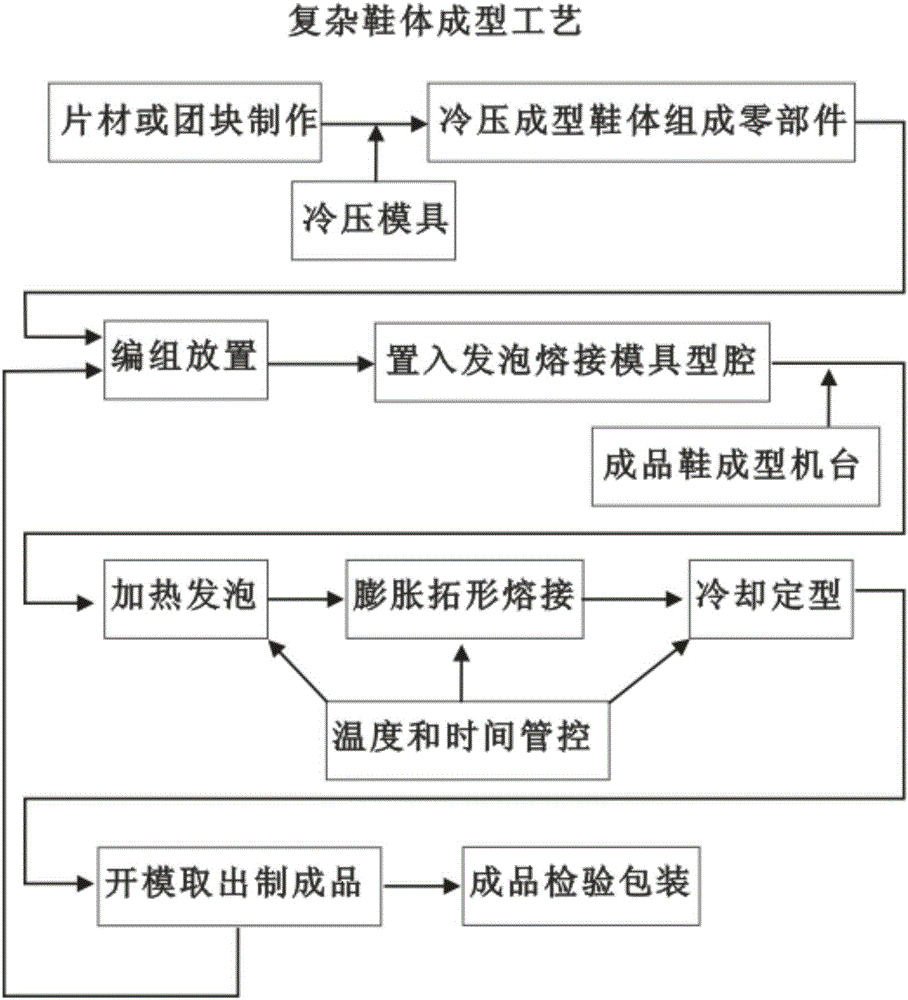

Foaming, welding, forming and manufacturing process of complex shoe body

A manufacturing process and shoe body technology, which is applied to footwear, other household appliances, household appliances, etc., can solve the problems of complex production of shoe soles, fragile molds, and difficult production, and achieve simple and reliable structure, low cost, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

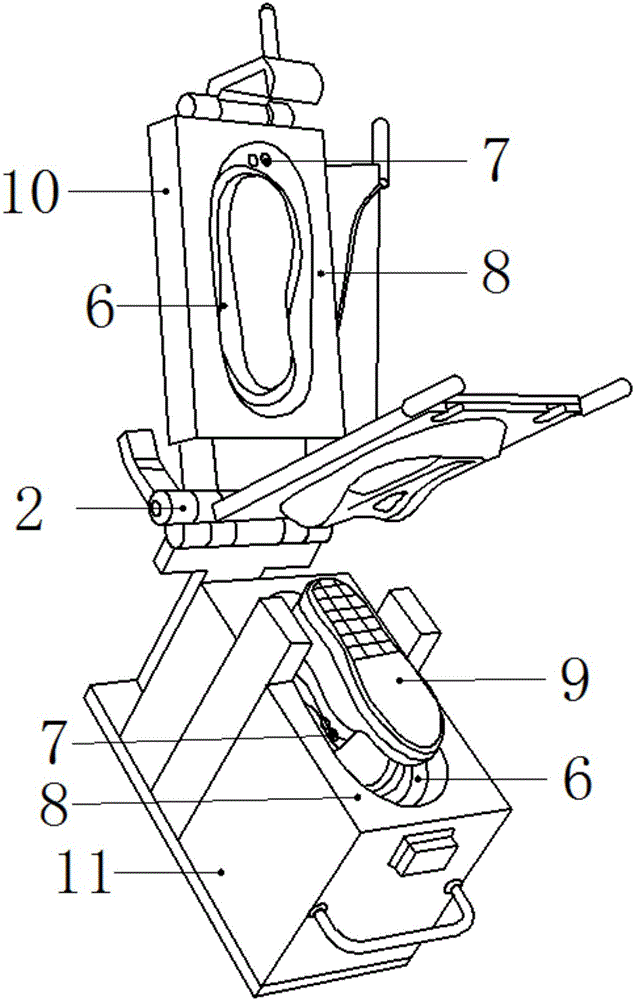

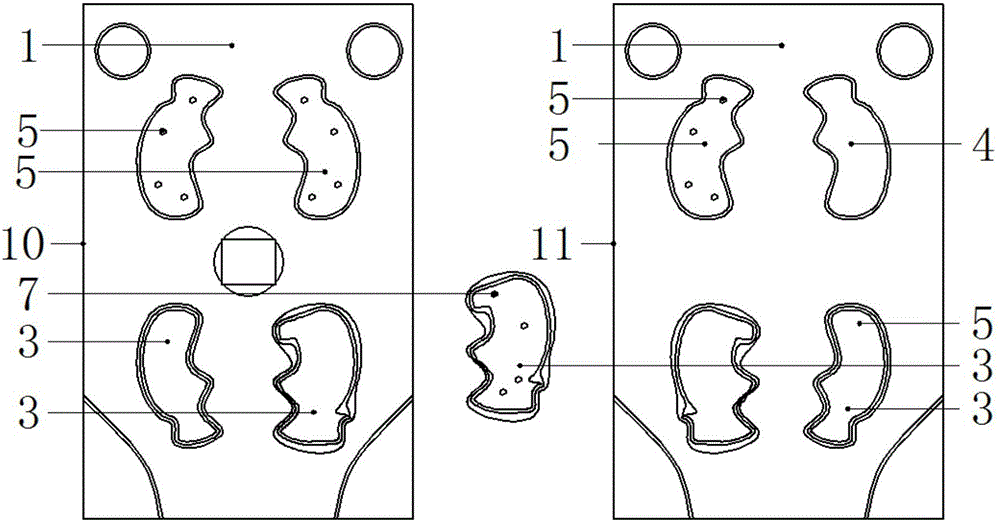

[0034] refer to Figure 1-Figure 3 As shown, a complex shoe body foam welding molding manufacturing process, the complex shoe body formed by the target has more complex convex-concave textures or holes or color blocks, and the molding process materials include shoe materials containing unexcited block foaming agents, Cold pressing mold, foam welding mold and finished shoe molding machine, including the following molding operation steps:

[0035] Step 1). Make the shoe material of unactivated block foaming agent into a sheet or agglomerate;

[0036] Step 2). Put the sheet or agglomerate of the unactivated block foaming agent shoe material into a cold pressing mold, press the sheet or agglomerate and cut it into a plurality of miniature shoe body components;

[0037] Step 3). Put the reduced version of the shoe body components togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com