High-speed rail unballasted double-track pavement multifunctional intelligent vehicle

A smart car and multi-functional technology, applied in the field of automation, can solve the problems of low engine power, time-consuming and labor-intensive operation, and confusion on the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

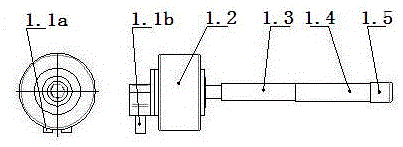

[0026] Depend on figure 1 As shown in: the present invention implements the structure of "automatic tightening and dismounting device for four elastic fasteners": the features include oil inlet joint (1.1a), oil outlet joint (1.1b), hydraulic motor (1.2), torque pressure sensor (1.3 ), a telescopic oil cylinder (1.4), and a sleeve wrench (1.5); there is a through hole in the middle of the hydraulic motor (1.2), and a torque and pressure sensor (1.3) and a telescopic oil cylinder (1.4) are installed in the middle of the through hole. Bolt sleeve wrench (1.5) is installed at the lower end of the telescopic oil cylinder (1.4), and they are connected end to end to form a "spring bolt tightening and dismounting device";

[0027] After starting up: the program controller outputs two commands successively to open the respective hydraulic valves, one is to fill oil to the lower nozzle of the telescopic cylinder (1.4), and the other is to fill oil to the forward rotation nozzle of the...

Embodiment approach 2

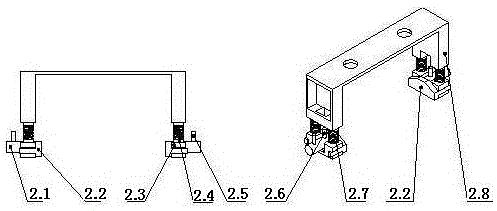

[0030] Depend on figure 2 As shown in the figure: the present invention installs the structure of "four spring fasteners pushing in place device" inside and outside the two rails at the front end of the smart car. The device will automatically push the four spring fasteners on the ballastless concrete sleeper to the pressure The design position of the tight rail, wherein the device consists of a cylinder (2.1), a push block (2.2), a cylinder support (2.3), a shaft (2.4), a forward oil port (2.5), a backward oil port (2.6), a spring (2.7 ), body (2.8) composition;

[0031] Elastic strip push upper device installs oil cylinder (2.1), push block (2.2), shaft (2.4) and spring (2.7) on the oil cylinder support (2.3) to form a single body, and then install the four single bodies on the two bodies (2.8) constitutes a "four-bar push-up device";

[0032] Its working principle is: when the "four elastic strips push the upper position device" moves to the pre-positioned position of th...

Embodiment approach 3

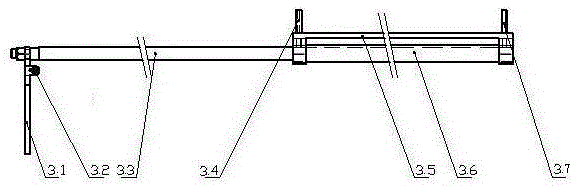

[0034] Depend on image 3 Shown in: the present invention implements and installs "smart car automatic stepping device" in the two rails below the smart car chassis, and the work of this device makes the smart car automatically step forward according to the program; Ratchet mechanism (3.2), oil cylinder shaft (3.3), oil inlet (3.4), mounting base (3.5), stepping oil cylinder (3.6), oil outlet (3.7);

[0035] When the "automatic stepping device" works, the program controller instructs to open the A hydraulic valve, and the A hydraulic valve fills the oil inlet (3.7) of the stepping oil cylinder (3.6), so that the oil cylinder shaft (3.3) is stretched out, and the oil cylinder shaft ( 3.3) It drives the ratchet wheel mechanism (3.2) and soles of the feet (3.1), and waits for the order after stretching out a set distance; when the bolts are tightened and the gauge locking device is finished, the system sends an instruction to open B hydraulic valve, B hydraulic valve fills the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com