LVDS (Low Voltage Differential Signaling) connector

A technology of connectors and connecting parts, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve problems such as easy separation of line boards and board ends, unstable performance, hidden dangers of product quality, etc., to improve firmness , Structural stability, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

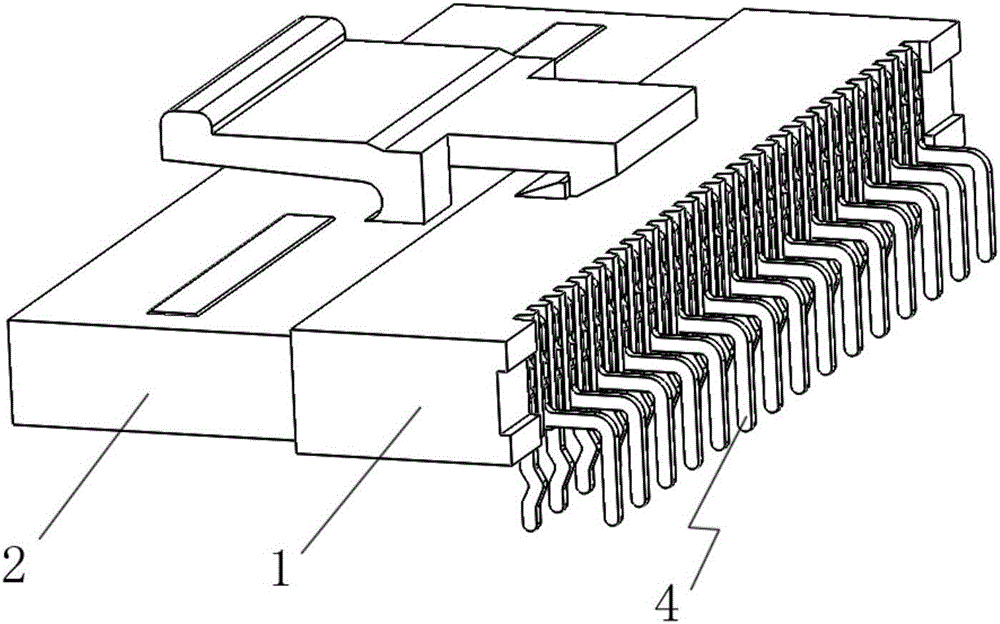

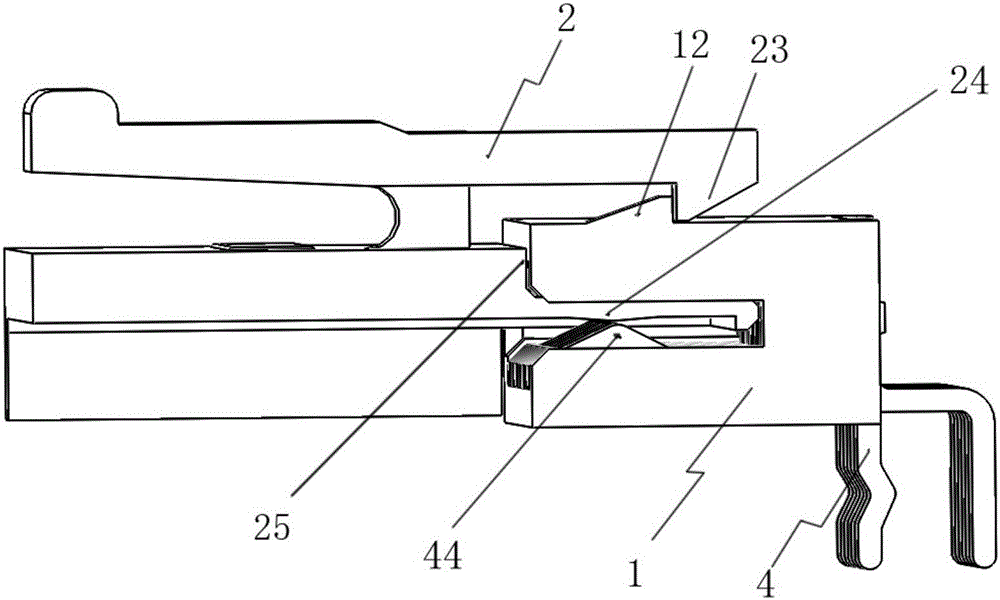

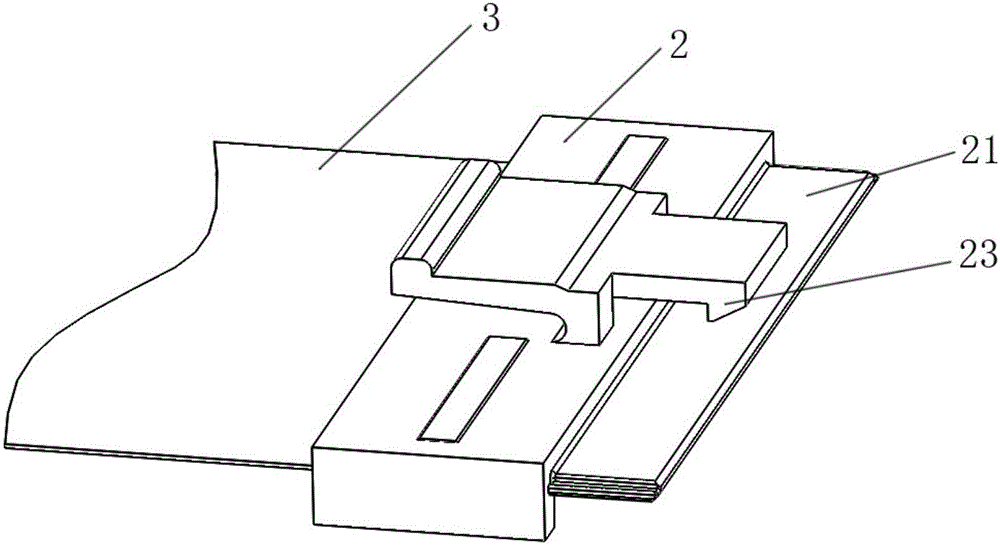

[0060] This embodiment provides as Figure 1-11 The illustrated LVDS connector includes an FFC line end and an LVDS board end, the LVDS board end shown and the FFC line end mated with it, wherein the FFC line end includes a cover body and an FFC line row, and the The cover body 2 has a mounting surface 21, and a limiting edge 22 formed by extending outward from one end of the mounting surface 21; the FFC line row 3 is horizontally installed on the mounting surface 21 through a mounting structure, and the FFC line The line end 31 of the row 3 is flush with the limit edge 22; further, the LVDS board end includes a base and a terminal part, and the base 1 is provided with a mounting groove for accommodating the FFC line row 3 and The terminal grooves 11 of several connection terminals arranged at intervals in the length direction of the installation groove, the terminal grooves extend outward from the front end of the base 1 where the installation groove is located to the rear en...

Embodiment 2

[0071] An LVDS connector provided in this implementation includes the FFC terminal described in Embodiment 1. Also includes such as Figure 7-8 An LVDS board header shown.

[0072] The LVDS board end includes a base and a third terminal, wherein the base 1 is provided with an accommodating space and several terminal slots 11 connected to the accommodating space, and at both ends of the base 11 in the length direction The fixing piece 13 is installed and fixed for fixing and maintaining the stability of the base; the third terminal 45 is arranged in the terminal slot 11 and extends straight out of the terminal slot 11 .

[0073] Further preferably, the third terminal 45 includes pin ends extending out of the base 1 and aligned horizontally. In this embodiment, the installation method of the third terminal adopts the board-end horizontal SMT specification (SMT is a mounting technology), and automatic assembly can be used when assembling with the base 1, which is convenient for...

Embodiment 3

[0075] An LVDS connector provided in this implementation includes the FFC terminal described in Embodiment 1. Also includes such as Figure 9-10 An LVDS board header shown.

[0076] The LVDS board end includes a base and a fourth terminal, wherein the base 1 is provided with an accommodating space and several terminal grooves 11 connected to the accommodating space, and the two ends in the length direction of the base are used For a fixed snap-in structure; specifically, the snap-in structure includes slots at both ends of the base, and two connectors 14 that are suitable for insertion into the slots, and the connectors are preferably snap-in slots. The hook can be used to fix the supporting base in different installation positions.

[0077] Further preferably, the fourth terminal 46 is disposed in the terminal groove 11 and extends straight out of the terminal groove 11 , including pin ends extending bidirectionally in the height direction of the base 1 . In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com