Synthesis method of solid waste multi-stage hole block body ECR-1 zeolite

A technology of ECR-1 and hole blocks, which is applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of not using seed crystal guidance, not finding crystal seed guidance, long crystallization cycle, etc. Achieve low cost, realize high value-added utilization, and shorten crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

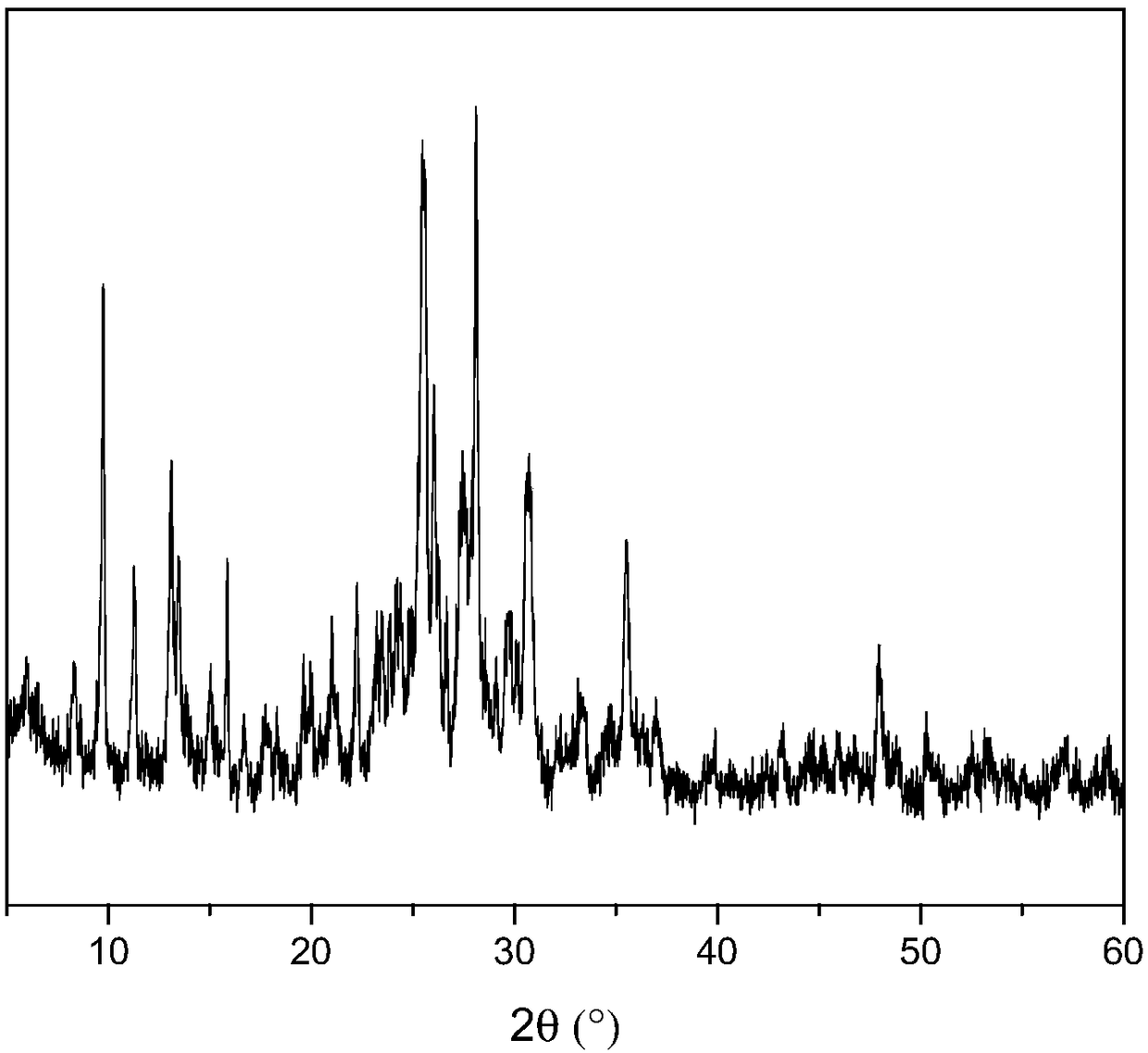

[0071] Accurately weigh silica fume, metakaolin, mordenite seed crystals, sodium hydroxide, and deionized water in a mass ratio of 2.3:1:0.2:0.5:1.57. Put the silica fume, metakaolin and mordenite seeds into the mixer and stir to form a mixture; dissolve the solid sodium hydroxide into deionized water, then pour the sodium hydroxide aqueous solution into the mixer containing the mixture and then stir , to form a uniformly mixed slurry; put the slurry into a 2cm×2cm×2cm six-joint steel mold, and vibrate it on a plastic sand vibrating table; seal the mold with a plastic film sealing bag, and place it in a constant temperature box at 50°C Cured for 24 hours, then removed from the mold to obtain a block test piece, put the block test piece into the reaction kettle, added 75mL deionized water, and sealed the kettle; 180°C hydrothermal reaction for 24 hours, took it out, washed it, dried it, and obtained a multi-level hole Bulk ECR-1 zeolite molecular sieve. figure 1 Figure a shows...

Embodiment 2

[0076] Accurately weigh silica fume, metakaolin, mordenite seed crystals, sodium hydroxide, and deionized water in a mass ratio of 2.3:1:0.2:0.5:1.57. Put the silica fume, metakaolin and mordenite seeds into the mixer and stir to form a mixture; dissolve the solid sodium hydroxide into deionized water, then pour the sodium hydroxide aqueous solution into the mixer containing the mixture and then stir , to form a uniformly mixed slurry; put the slurry into a 2cm×2cm×2cm six-joint steel mold, and vibrate it on a plastic sand vibrating table; seal the mold with a plastic film sealing bag, and place it in a constant temperature box at 50°C Cured for 24 hours, then removed from the mold to obtain a block test piece, put the block test piece into the reaction kettle, added 75mL deionized water, and sealed the kettle; 180°C hydrothermal reaction for 48 hours, took it out, washed it, and dried it to obtain a multi-level hole Bulk ECR-1 zeolite molecular sieve. figure 1 Figure b shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com