Method for extracting natural gas hydrate by using gas mixture of CO2 and H2

A technology of mixed gas and mixed gas, which is applied in the development of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of low CH4 content, low industrial application value, and increase the overall cost, so as to improve the production efficiency. , Overcome the effect of low methane mole fraction and reduce mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

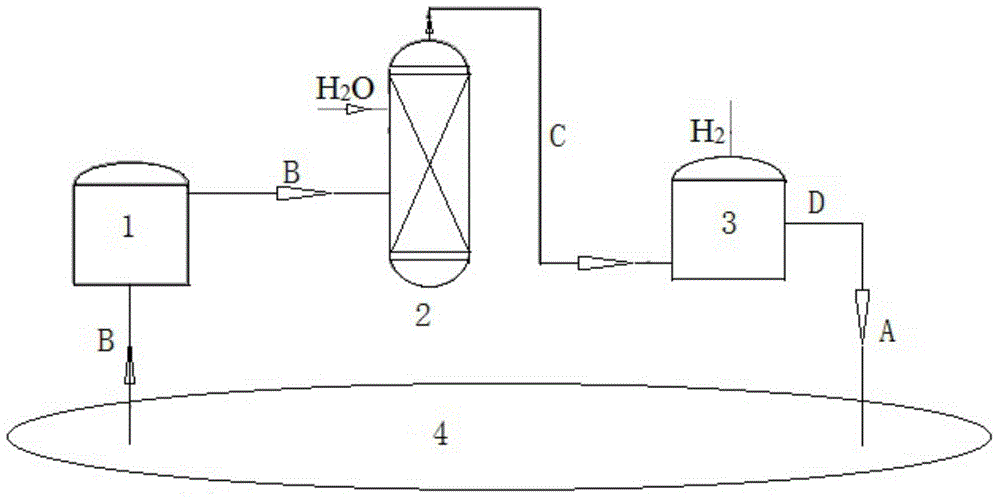

[0046] This embodiment provides a CO 2 and H 2 The method of gas hydrate recovery with mixed gas, using such as figure 1 Shown device, this device comprises gas-liquid separation device 1, CH 4 Steam reforming device 2, mixed gas separation device 3. The device communicates with the natural gas hydrate reservoir 4 . The gas-liquid separation device 1 is connected with the natural gas hydrate reservoir 4 through conventional methods, and the gas-liquid separation device 1 is connected with the CH 4 Steam reforming unit 2-phase communication, CH 4 The steam reforming device 2 is connected with the mixed gas separation device 3 through conventional methods, and the mixed gas separation device 3 is connected with the natural gas hydrate reservoir 4 through conventional methods.

[0047] The use of CO provided by this example 2 and H 2 The method for recovering natural gas hydrate with mixed gas comprises the following steps:

[0048] Firstly, the conventional decompression...

Embodiment 2

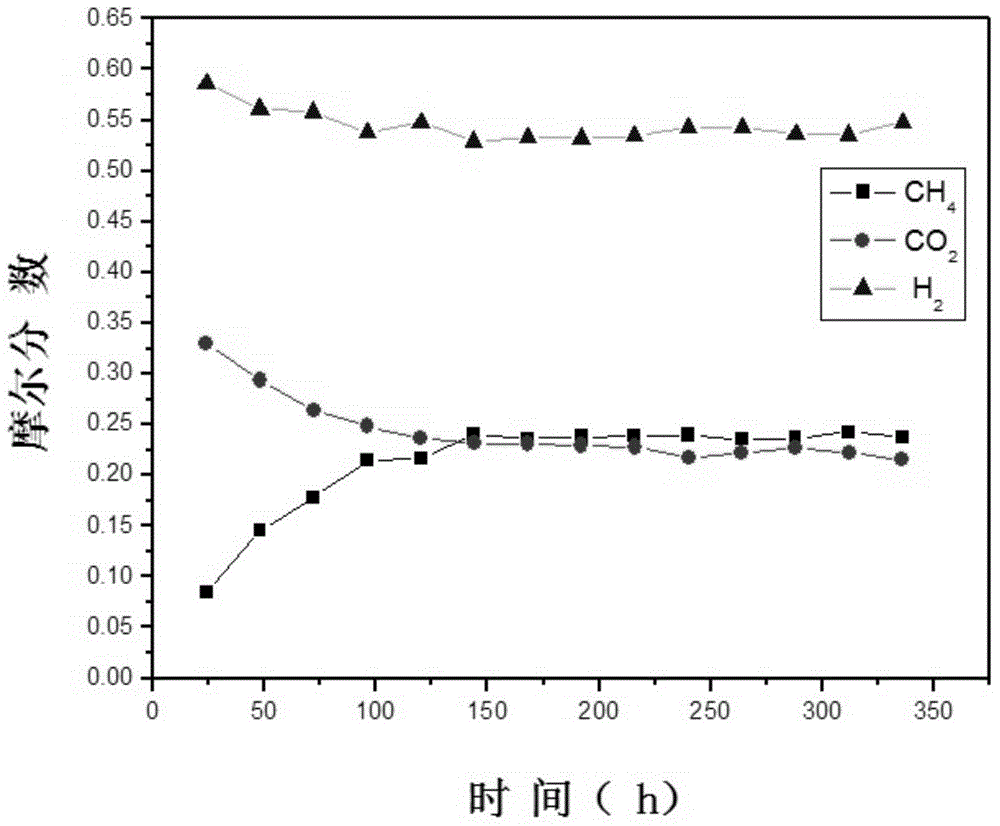

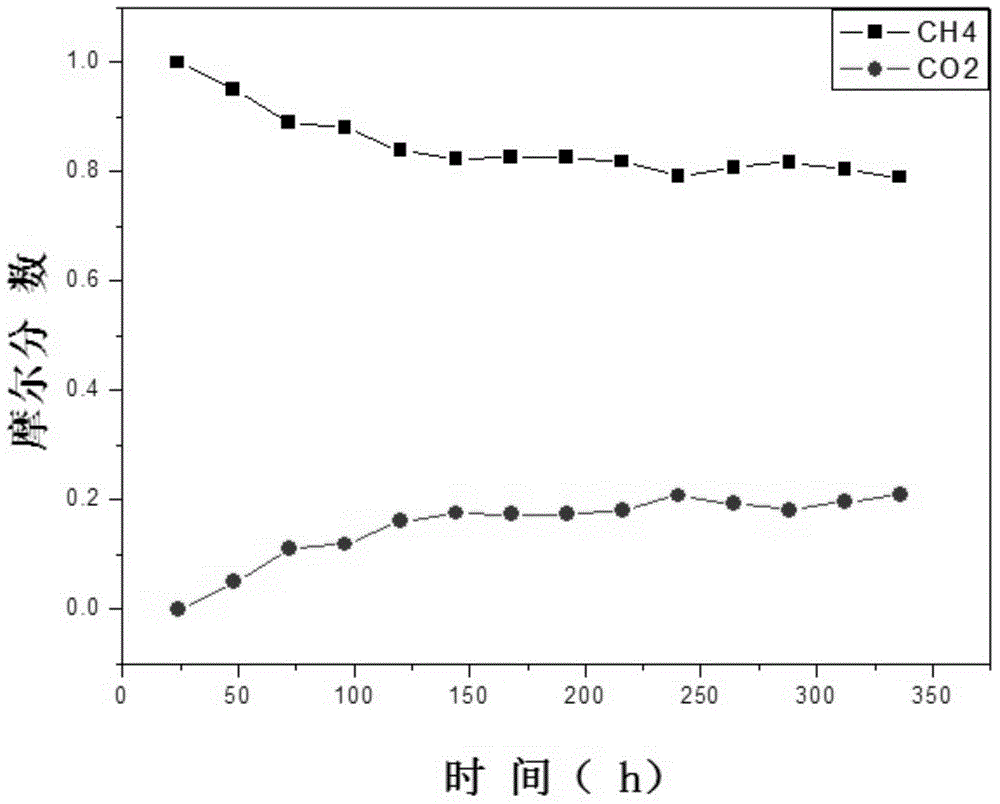

[0055] This example uses CO 2 and H 2 Experiments were carried out on the method of exploiting natural gas hydrate with mixed gas, and the effect of each mixed gas on CH was calculated. 4 The optimal recovery rate of hydrate and the H 2 highest recovery rate. The method mainly consists of three parts: hydrate sample preparation, depressurization gas injection, and displacement mining, and specifically includes the following steps:

[0056] Hydrate sample preparation: prepare CH at 271.2K to 273.2K, 8.0-10.0MPa 4 Hydrate samples;

[0057] Pressure-reducing gas injection: reduce the pressure to 3.0MPa (above the stable pressure of hydrate) through slow exhaust, keep the pressure constant, and inject the mixed gas (CO 2 and H 2 ) continuous injection of CH 4 In hydrate samples, to CH 4 Free CH in hydrate samples 4 The content is less than 2%;

[0058] Replacement mining: continue to inject the mixed gas to 5.0MPa, and start to enter the replacement stage; the mixed gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com