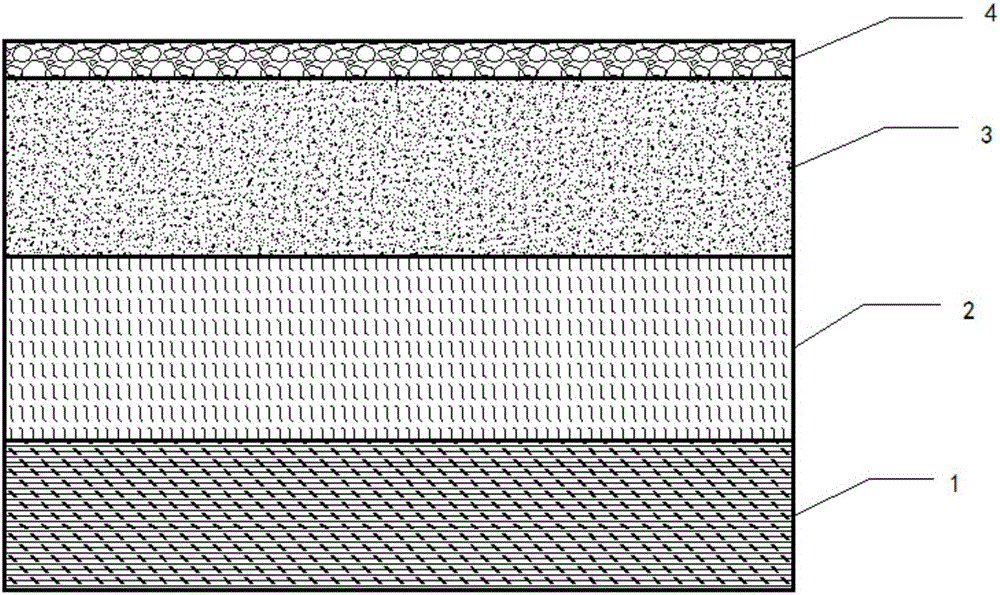

Organic fertilizer brick of four-layered structure and preparation method of organic fertilizer brick

A technology of organic fertilizer and layer structure, applied in the direction of organic fertilizer, inorganic fertilizer, botanical equipment and methods, etc., can solve the problems of changing soil structure, unfavorable seed growth, troubles, etc., to strengthen and consolidate plant root system, long-term and effective repellent Insect bacteriostatic effect and the effect of improving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] 1. Preparation of aquifers

[0053] Dry the leaves of the conventional broad-leaved forest and cut them into multiple leaves; dry the algae and cut them into 2 mm long algae segments; dry the moss and cut it into pieces to obtain moss powder; dry and grind 2 g of tangerine peel and 1 g of ginger Then mix with 5g of camphor wood powder to obtain powder; mix 40g of leaves, 30g of algae segment, 10g of moss powder and the powder, pave and press evenly to obtain the aquifer;

[0054] 2. Preparation of fiber layer

[0055] Mix and grind 30g of mango inner shell fiber and 10g of loofah to obtain mixed fiber, then mix the obtained mixed fiber with 10g of sand to obtain a fiber mixture; 20g of clay and water are obtained in a ratio of 1:1 to obtain mud; the obtained mud mixed with a fiber mixture and shaped into a brick structure to obtain said fiber layer;

[0056] 3. Preparation of organic fertilizer layer

[0057] Mix 30g of mango inner shell fragments, 20g of discarded t...

example 2

[0060] 1. Preparation of aquifers

[0061] Dry the leaves of the conventional broad-leaved forest and cut them into multiple leaves; dry the algae and cut them into 5 mm long algae segments; dry the moss and cut it into pieces to obtain moss powder; dry and grind 5 g of tangerine peel and 3 g of ginger Then mix with 10g of camphor powder to obtain powder; mix 60g of leaves, 50g of algae segment, 15g of moss powder and the powder, pave and press evenly to obtain the aquifer;

[0062] 2. Preparation of fiber layer

[0063] Mix and grind 45g of mango inner shell fiber and 15g of loofah to obtain mixed fiber, then mix the obtained mixed fiber with 20g of sand to obtain a fiber mixture; 30g of clay and water are obtained in a ratio of 2:1 to obtain mud; the obtained mud mixed with a fiber mixture and shaped into a brick structure to obtain said fiber layer;

[0064] 3. Preparation of organic fertilizer layer

[0065] Mix 50g of mango inner shell fragments, 30g of discarded tea l...

example 3

[0068] 1. Preparation of aquifers

[0069] Dry the leaves of conventional broad-leaved forest and eucalyptus leaves and cut them into multiple leaves; dry the algae and cut them into 2-5mm long algae segments; dry the moss and cut it into pieces to obtain moss powder; 2 g of orange peel and Ginger 3g is dried and ground and mixed with the camphor powder to obtain a powder; 60g of the leaves (including 56g of conventional broad-leaved forest leaves and 4g of eucalyptus leaves), 50g of algae segments, 15g of moss powder and the powder are mixed After the pavement is evenly pressed together to obtain the aquifer;

[0070] 2. Preparation of fiber layer

[0071] Mix and grind 45g of mango inner shell fiber and 15g of loofah to obtain mixed fiber, then mix the obtained mixed fiber with 20g of sand to obtain a fiber mixture; 30g of clay and water are obtained in a ratio of 2:1 to obtain mud; the obtained mud mixed with a fiber mixture and shaped into a brick structure to obtain sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com