Conductive paste for high-performance solar cell and preparation method thereof

A technology for solar cells and conductive paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of restricting the performance of solar cells, poor comprehensive performance, and low conversion efficiency, etc. Achieve excellent conversion efficiency, excellent performance, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

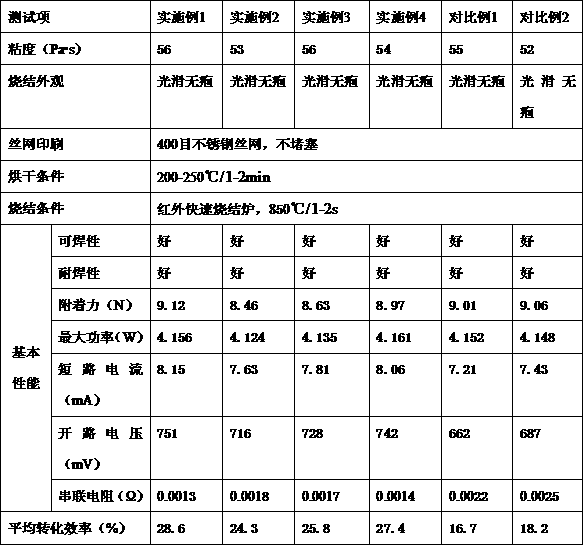

Examples

Embodiment 1

[0025] A high-performance conductive paste for solar cells, prepared from the following raw materials in parts by weight: 70 parts of lauric acid modified conductive nano powder, 9 parts of glass powder, 10 parts of long-oil alkyd resin, and 11 parts of polystyrene resin 4.5 parts of carboxylated nitrile rubber, 7 parts of propylene glycol methyl ether acetate, 5.5 parts of rosin maleate, 8 parts of dihydroxyethyl methacrylate, 3.5 parts of propylene glycol monobutyl ether, trioctyl trimellitate 2 parts of ester, 4 parts of zinc naphthenate, 2.5 parts of lubricant, 3 parts of coalescent, 2 parts of thickener;

[0026] The composition of described glass powder is: Al 2 o 3 , ZrO 2 , TeO 2 , MnO, SiO 2 , and its mass ratio is 5:9:5:10:18.

[0027] The film-forming aid is pentaerythritol fat.

[0028] Described lubricant is vinylbisstearamide.

[0029] The thickener is sodium carboxymethylcellulose.

[0030] The preparation method of high-performance conductive paste of t...

Embodiment 2

[0035] A high-performance conductive paste for solar cells, prepared from the following raw materials in parts by weight: 60 parts of lauric acid modified conductive nano powder, 6 parts of glass powder, 5 parts of long oil alkyd resin, 7 parts of polystyrene resin 3 parts of carboxylated nitrile rubber, 5 parts of propylene glycol methyl ether acetate, 3 parts of rosin maleate, 6 parts of dihydroxyethyl methacrylate, 2 parts of propylene glycol monobutyl ether, trioctyl trimellitate 1 part of ester, 2 parts of zinc naphthenate, 1 part of lubricant, 1 part of coalescent, 1 part of thickener;

[0036] The composition of described glass powder is: Al 2 o 3 , ZrO 2 , TeO 2 , MnO, SiO 2 , and its mass ratio is 2:5:3:6:12.

[0037] The film-forming aid is polyvinyl alcohol.

[0038] The lubricant is lanolin.

[0039] The thickener is hydroxypropyl methylcellulose.

[0040] The preparation method of high-performance conductive paste of the present invention, comprises the foll...

Embodiment 3

[0045] A high-performance conductive paste for solar cells, prepared from the following raw materials in parts by weight: 65 parts of lauric acid modified conductive nano powder, 8 parts of glass powder, 7 parts of long oil alkyd resin, 10 parts of polystyrene resin 4 parts of carboxylated nitrile rubber, 6 parts of propylene glycol methyl ether acetate, 5 parts of rosin maleate, 7 parts of dihydroxyethyl methacrylate, 3 parts of propylene glycol monobutyl ether, and trioctyl trimellitate 1.5 parts of ester, 3 parts of zinc naphthenate, 2 parts of lubricant, 2 parts of coalescent, 1.5 parts of thickener;

[0046] The composition of described glass powder is: Al 2 o 3 , ZrO 2 , TeO 2 , MnO, SiO 2 , and its mass ratio is 3:7:4:8:15.

[0047] The film-forming aid is pentaerythritol fat.

[0048] The lubricant is silicone oil.

[0049] The thickener is polyacrylamide.

[0050] The preparation method of high-performance conductive paste of the present invention, comprises t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com