Production method of W/O blueberry anthocyanin micro-emulsion

A blueberry anthocyanin, water-in-oil type technology, applied in the field of production of water-in-oil blueberry anthocyanin microemulsion, can solve the problems of low solubility and low stability, and achieve good fat solubility and stability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

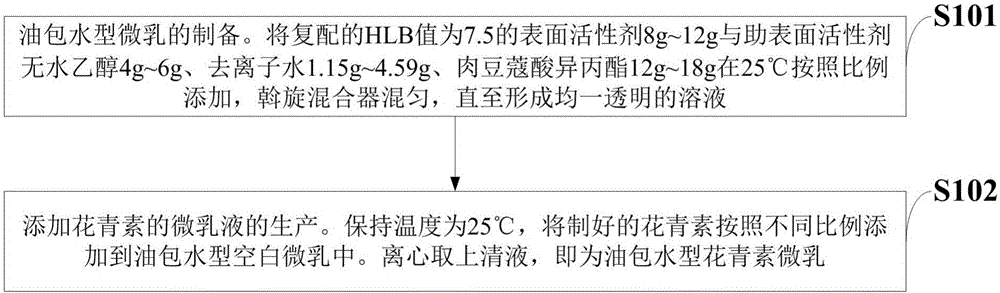

[0029] Step 1, preparation of water-in-oil microemulsion. Add 8g of the compounded surfactant with an HLB value of 7.5, 4g of co-surfactant anhydrous ethanol, 1.15g of deionized water, and 18g of isopropyl myristate at 25°C in proportion, and mix well with a mediation mixer until Form a homogeneous and transparent solution;

[0030] Step 2, adding the production of anthocyanin microemulsion. Keeping the temperature at 25°C, the prepared anthocyanins were added to the water-in-oil blank microemulsion in different proportions. Centrifuge to get the supernatant, which is the water-in-oil type anthocyanin microemulsion.

Embodiment 2

[0032] Step 1, preparation of water-in-oil microemulsion. Add 10 g of the compounded surfactant with an HLB value of 7.5, 5 g of co-surfactant anhydrous ethanol, 2.73 g of deionized water, and 15 g of isopropyl myristate at 25°C in proportion, and mix well with a mediation mixer until Form a homogeneous and transparent solution;

[0033] Step 2, adding the production of anthocyanin microemulsion. Keeping the temperature at 25°C, the prepared anthocyanins were added to the water-in-oil blank microemulsion in different proportions. Centrifuge to get the supernatant, which is the water-in-oil type anthocyanin microemulsion.

Embodiment 3

[0035] Step 1, preparation of water-in-oil microemulsion. Add 12g of the compounded surfactant with an HLB value of 7.5, 6g of co-surfactant anhydrous ethanol, 4.59g of deionized water, and 12g of isopropyl myristate at 25°C in proportion, and mix well with a mediation mixer until Form a homogeneous and transparent solution;

[0036] Step 2, adding the production of anthocyanin microemulsion. Keeping the temperature at 25°C, the prepared anthocyanins were added to the water-in-oil blank microemulsion in different proportions. Centrifuge to get the supernatant, which is the water-in-oil type anthocyanin microemulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com