Method for ultrasonic alkali treatment-based dual-enzyme degradation of bagasse

A technology of ultrasonic and alkali treatment, applied in the field of bagasse resource utilization, can solve the problem that the effect is not obvious, and achieve the effects of low cost, less by-products, and improved degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

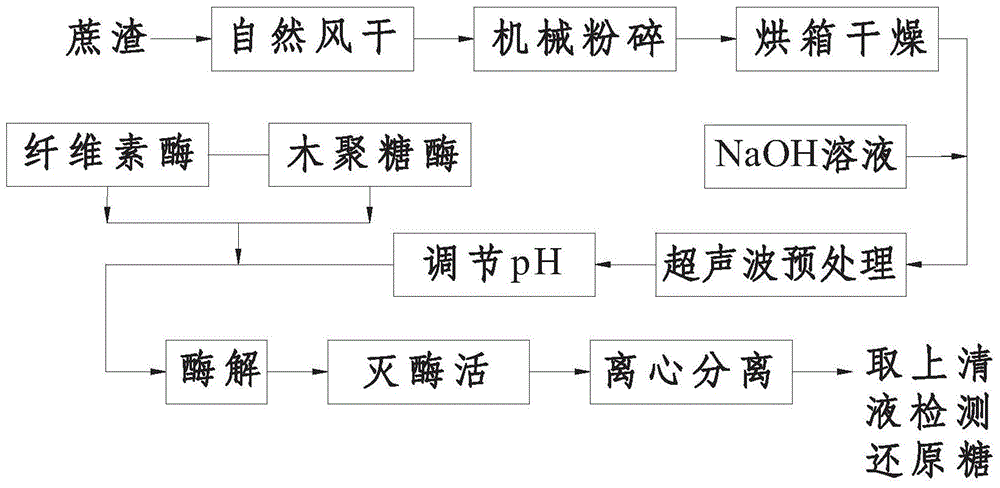

Method used

Image

Examples

Embodiment 1

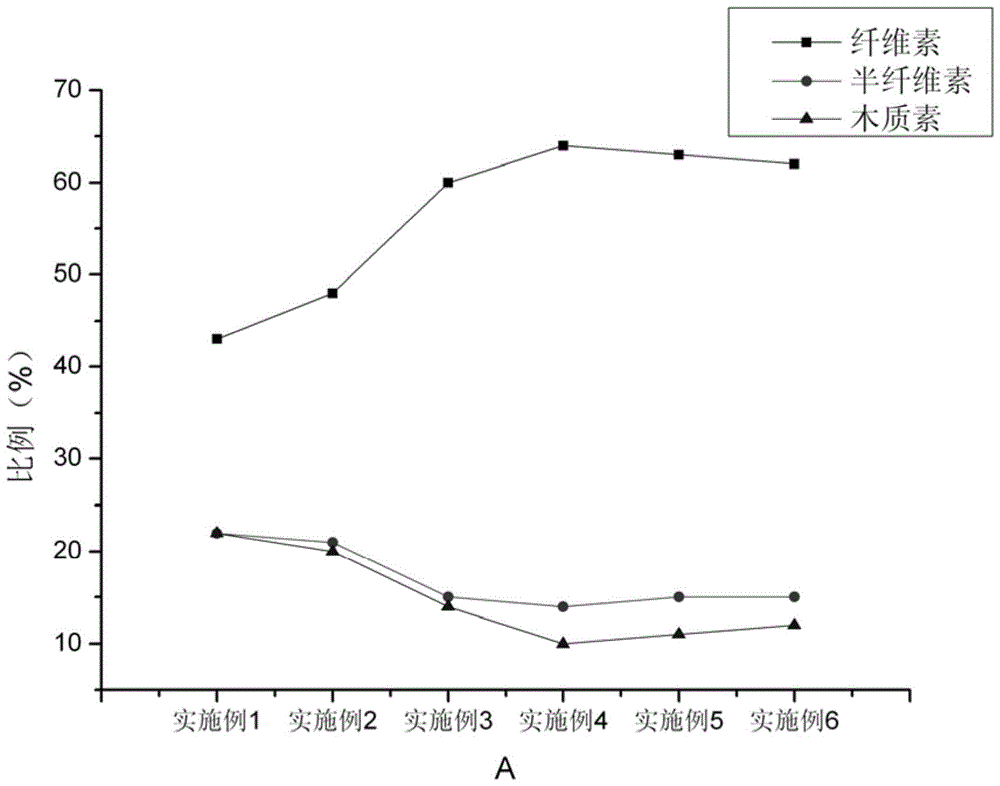

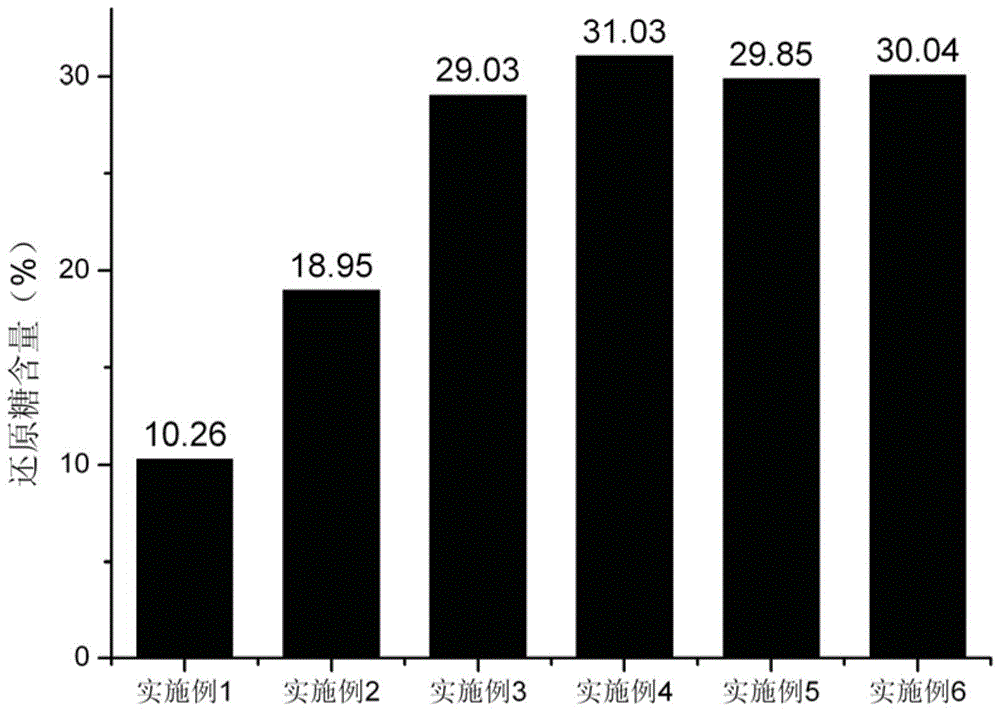

[0026] Place the bagasse in a dry and ventilated condition to air-dry, crush the air-dried bagasse with a mechanical mixer and sieve (60 mesh), put the sieved bagasse in an oven at 105°C to dry to remove its moisture to constant Re-obtain bagasse powder; in the bagasse powder after drying, pour NaOH solution (mass concentration is 2%) by the solid-to-liquid mass volume ratio 1: 12 of bagasse powder and NaOH solution, and carry out pretreatment with ultrasonic cleaner (power 200W, time 40min); use 10-20ml of sodium citrate buffer to adjust the pH of the system to 4 and add cellulase (0.05g / g bagasse) and xylanase (0.1g / g bagasse) for enzymolysis reaction for 32h (The reaction temperature is 50° C.), and the enzymolysis solution after enzymolysis was treated at 95° C. for 3 hours to inactivate the enzyme. Afterwards, centrifuge with a centrifuge (rotating speed 3000 rap, time 15 min), take the supernatant and use the DNS method to measure the reducing sugar content.

[0027] Re...

Embodiment 2

[0029] Place the bagasse in a dry and ventilated condition to air-dry, crush the air-dried bagasse with a mechanical mixer and sieve (60 mesh), put the sieved bagasse in an oven at 105°C to dry to remove its moisture to constant Re-obtain bagasse powder; in the bagasse powder after drying, pour NaOH solution (mass concentration is 3%) by the solid-to-liquid mass volume ratio 1: 13 of bagasse powder and NaOH solution, and carry out pretreatment with ultrasonic cleaner (power 300W, time 50min); use 10-20ml of sodium citrate buffer to adjust the pH of the system to 5 and add cellulase (0.07g / g bagasse) and xylanase (0.2g / g bagasse) for enzymolysis reaction for 32h (The reaction temperature is 50° C.), and the enzymolysis solution after enzymolysis was treated at 95° C. for 3 hours to inactivate the enzyme. Afterwards, centrifuge with a centrifuge (rotating speed 4000 rap, time 15 min), take the supernatant and use the DNS method to measure the reducing sugar content.

[0030] Re...

Embodiment 3

[0032] Place the bagasse in a dry and ventilated condition to air-dry, crush the air-dried bagasse with a mechanical mixer and sieve (80 mesh), put the sieved bagasse in an oven at 105°C to dry to remove its moisture to constant Re-obtain bagasse powder; in the bagasse powder after drying, pour NaOH solution (mass concentration is 5%) by the solid-to-liquid mass volume ratio 1: 14 of bagasse powder and NaOH solution, and carry out pretreatment with ultrasonic cleaner (power 300W, time 60min); use 10-20ml of sodium citrate buffer to adjust the pH of the system to 6 and add cellulase (0.08g / g bagasse) and xylanase (0.2g / g bagasse) for enzymolysis reaction for 35h (The reaction temperature is 50° C.), and the enzymolysis solution after enzymolysis was treated at 95° C. for 3 hours to inactivate the enzyme. Afterwards, centrifuge with a centrifuge (rotating speed 3000 rap, time 15 min), take the supernatant and use the DNS method to measure the reducing sugar content.

[0033] Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com