Degradable polypropylene plastic as well as preparation method and application thereof

A technology of polypropylene plastic and polypropylene, which is applied in the field of degradable polypropylene plastic and its preparation, can solve the problems of the use restriction of polypropylene plastic products, achieve the purpose of enhancing the bonding force, reducing the possibility of falling off, and reducing voids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] Preparation Example 1: A degradation agent. In this preparation example, each part of the degradation agent is made of raw materials with the particle size shown in Table 1 and the parts by weight shown in Table 2. The mode of preparation degradation agent is:

[0037] Add epoxy resin as a binder to the cellulose, stir evenly to form agglomerates of cellulose and epoxy resin, and ball-mill the agglomerates after natural drying to make the agglomerates larger in particle size, which is convenient for the activated carbon to densely wrap the cellulose. Mix the epoxy resin as the adhesive, the cobalt naphthenate as the accelerator, and the particles of the agglomerate, stir evenly, spray the agglomerate with the adhesive and accelerator on the outer layer into the hydrophobic activated carbon, and shake Stir, dry, and gently shake to remove the activated carbon that is not combined with the adhesive, and sieve with a sieve with a mesh number of 100. The degradant is on the...

preparation example 2-7

[0039] A degradation agent differs from Example 1 in that it is made from raw materials including the particle size shown in Table 1 and the weight shown in Table 2.

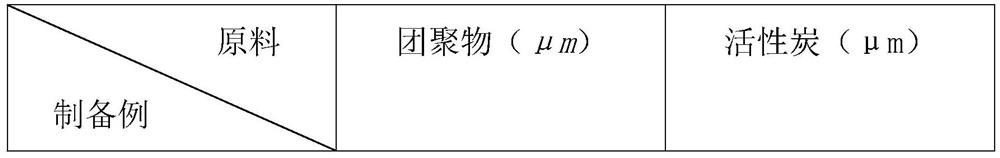

[0040] Raw material particle size in table 1 preparation example 1-7

[0041]

[0042]

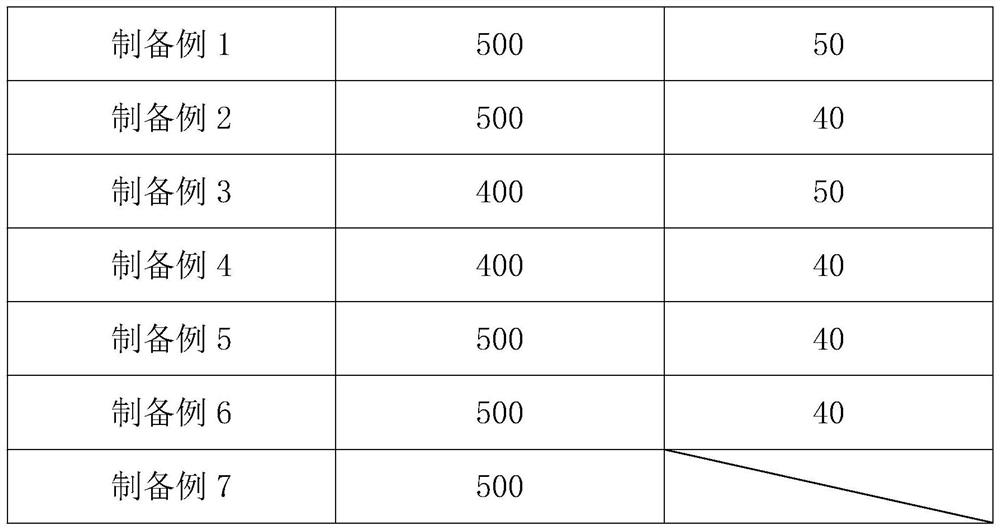

[0043] Raw materials and weight in table 2 preparation example 1-7

[0044]

preparation example 8

[0046] A degradation agent, the difference from Comparative Example 2 is that the activated carbon coated with cellulose is ordinary activated carbon.

[0047] Take 5cm 3The degradation agent prepared in Preparation Examples 1-8 was soaked in water for 8 hours at room temperature and then taken out for measurement.

[0048] Volume after degradation agent immersion in table 3 preparation example 1-8

[0049] Preparation example Degradant volume (cm 3 )

[0050] Test results and analysis: in conjunction with Preparation Examples 1-8 and Table 3, it can be seen that the volume of the degradation agent of Preparation Examples 1-6 does not increase significantly, and the volume of the degradation agent of Preparation Example 7 increases. Therefore, the outer coating of the aggregate is made of hydrophobic activated carbon. Compared with the uncoated hydrophobic activated carbon outside the agglomerate, the degradant has a reduced possibility of absorbing water and har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com