Quasi gradient-color ion enhanced secondary light source high-light-transmittance and photocorrosion-resistant concealed display composite material and preparation method thereof

An ion-enhanced, anti-light corrosion technology, applied in the field of polymers, can solve the problems of non-integrated parts, high cost of transparent materials, and expensive painting, and achieve low preparation costs, excellent anti-light corrosion, and transparent The effect of sharpness and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

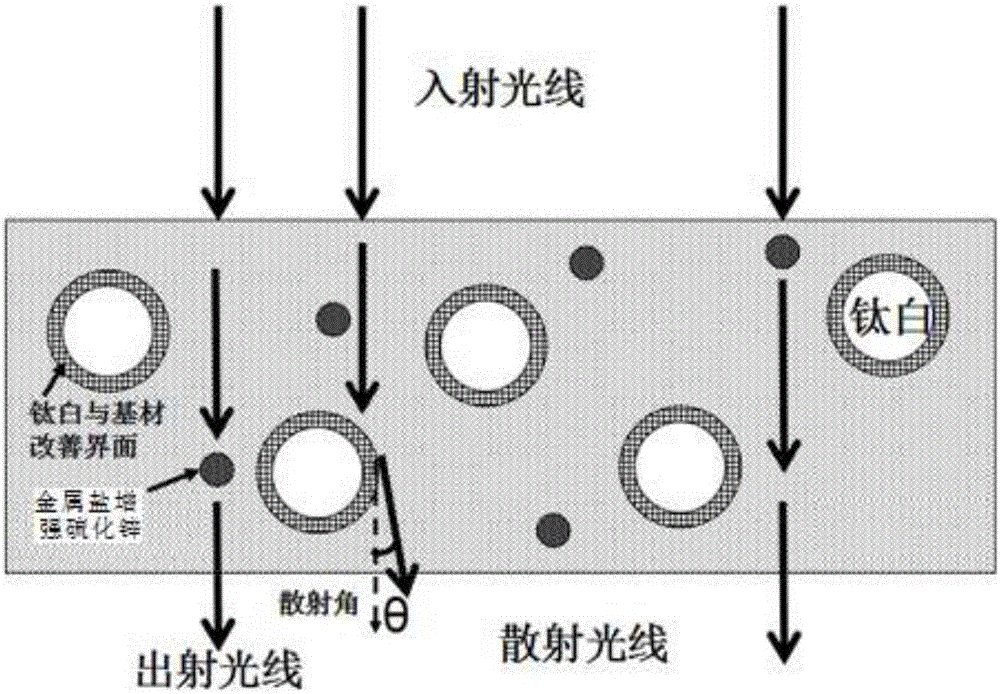

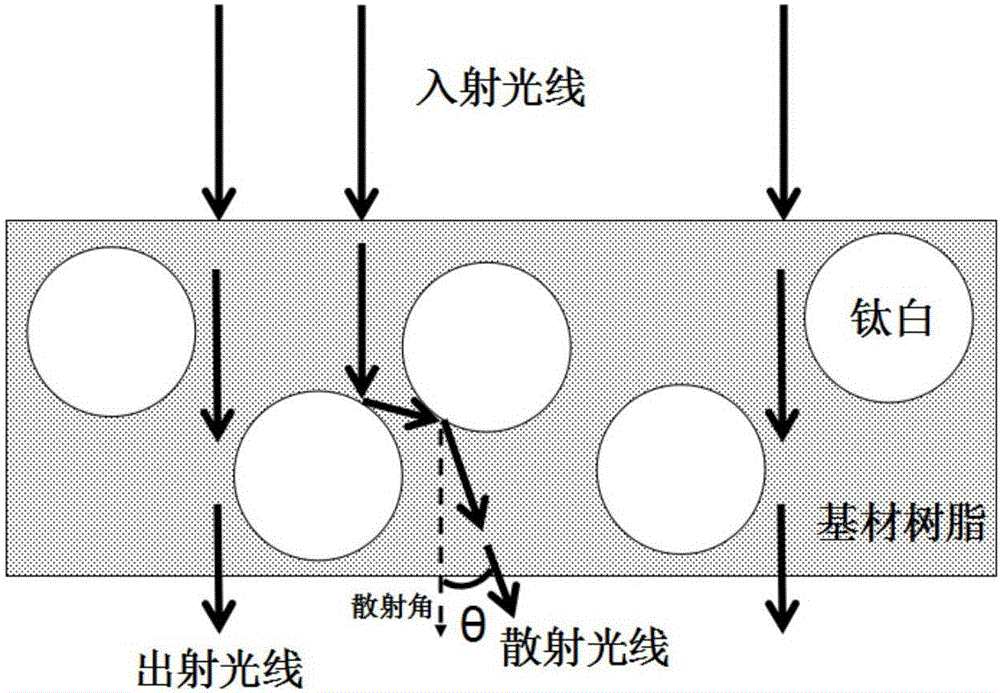

Method used

Image

Examples

Embodiment 1

[0034] The quasi-gradient color ion-enhanced secondary light source in this embodiment is composed of the following raw materials in parts by weight:

[0035]

[0036] Concrete preparation method comprises the following steps:

[0037] (1) Add the zinc sulfide raw material with micro-nano particle size into the deionized aqueous solution of Cu salt with a mass concentration of 0.1%, mix evenly, then put it into a box furnace for baking at 120°C, and ball mill for 48 hours after drying, and Put the ground powder into a quartz tube, burn at 900°C for 1 hour under a helium or nitrogen protective atmosphere, and sieve through a 8000-mesh sieve after natural cooling to prepare Cu 2+ Reinforced micronano particle size zinc sulfide powder.

[0038] (2) According to the proportion, 1 part of rutile titanium dioxide, 0.5 part of benzotriazole and hindered amine compound light stabilizer, 0.8 part of hindered phenol and phosphite compound antioxidant and 0.5 part of fatty acid amide...

Embodiment 2

[0042] The quasi-gradient color ion-enhanced secondary light source in this embodiment is composed of the following raw materials in parts by weight:

[0043]

[0044] Concrete preparation method comprises the following steps:

[0045] (1) The zinc sulfide raw material with micronano particle size is added to the deionized aqueous solution of Cu salt with a mass concentration of 0.05%, mixed evenly, then put into a box furnace for baking at 110°C, and ball milled for 50 hours after drying. Put the ground powder into a quartz tube, burn at 850°C for 80 minutes under a helium or nitrogen protective atmosphere, and sieve through a 8000-mesh sieve after natural cooling to prepare Cu 2+ Reinforced micronano particle size zinc sulfide powder.

[0046] (2) According to the ratio, 1 part of rutile titanium dioxide, 0.8 part of benzotriazole and hindered amine compound light stabilizer, 0.5 part of hindered phenol and phosphite compound antioxidant and 0.5 part of fatty acid amide ...

Embodiment 3

[0050] The quasi-gradient color ion-enhanced secondary light source in this embodiment is composed of the following raw materials in parts by weight:

[0051]

[0052] Concrete preparation method comprises the following steps:

[0053] (1) Add the zinc sulfide raw material with micro-nano particle size into the deionized aqueous solution of manganese salt with a mass concentration of 0.15%, mix evenly, then put it into a box furnace for baking at 130°C, and ball mill it for 40 hours after drying. Put the ground powder into a quartz tube, burn at 950°C for 1 hour under a protective atmosphere of helium or nitrogen, and sieve through a 8000-mesh sieve after natural cooling to prepare Cu 2+ Reinforced micronano particle size zinc sulfide powder.

[0054] (2) According to the proportion, 1 part of rutile titanium dioxide, 0.8 part of benzotriazole and hindered amine compound light stabilizer, 0.5 part of hindered phenol and phosphite compound antioxidant and 1 part of fatty ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com