High-temperature accumulation box and accumulation process

A high-temperature stacking and process technology, which is applied in the field of high-temperature stacking boxes and stacking processes, can solve the problems of affecting the fermentation effect, limited fermentation amount, and low work efficiency, and achieve the effects of ensuring the stacking effect, simple equipment structure, and increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

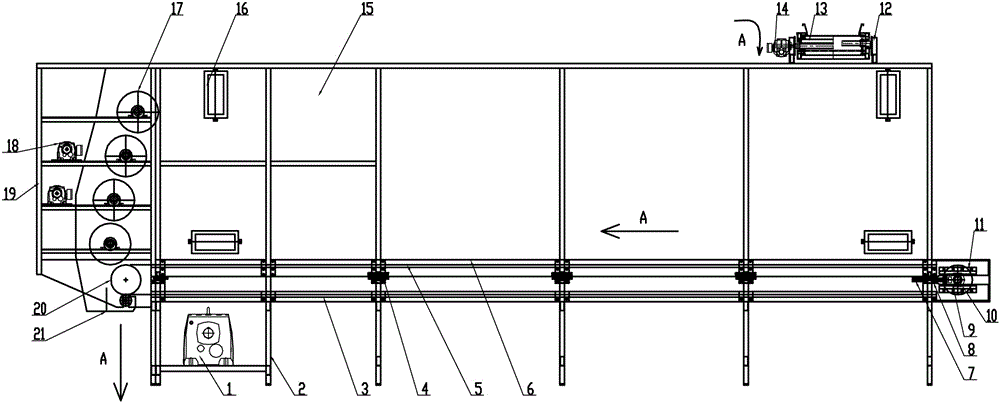

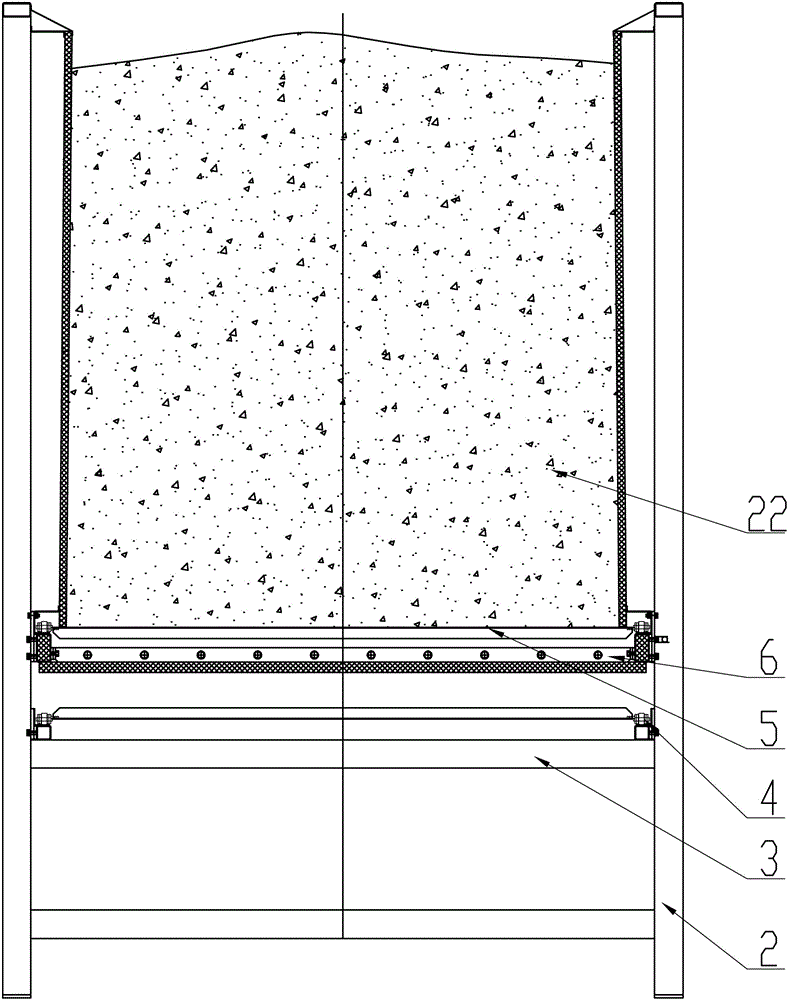

[0036] Such as Figure 1-3 As shown, the high-temperature stacking box includes a frame 2, an integral stacking translation device is installed in the middle of the frame 2, and stacking tank side plates 15 are installed on both sides of the integral stacking translation device, and the stacking tank side plates One end of the top of 15 is equipped with a uniform feeding device, and the other end is equipped with a rolling brush discharging device, and the end of the integral stacking translation device close to the rolling brush discharging device is equipped with a discharge hopper 21 . The material can be moved as a whole through the overall stacking translation device.

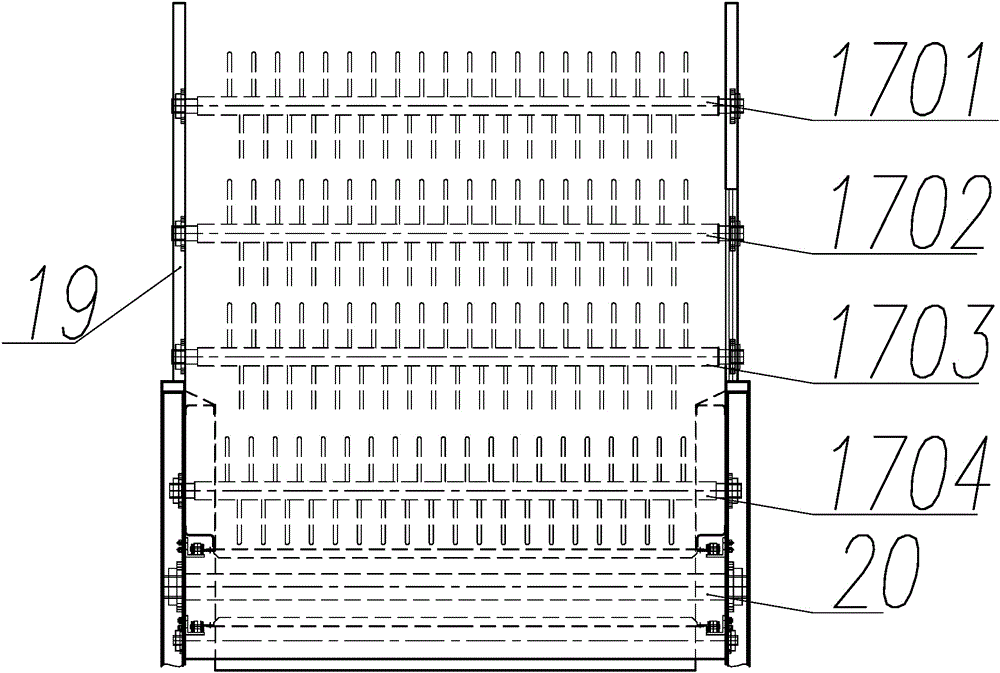

[0037] Further, the rolling brush discharge device includes a plurality of multi-stage stirring shaft devices 17, the main shaft of the multi-stage stirring shaft device 17 is supported and installed on the discharge bracket 19, and the discharge bracket 19 is fixedly installed on the overall pile At the ...

Embodiment 2

[0043] The operation method for high-temperature accumulation of distiller's grains by using a high-temperature accumulation box includes the following steps:

[0044] The first step is to scatter the material through the uniform unloading device so that it falls evenly inside the material accumulation box. By controlling the speed of the unloading motor 14, the speed of unloading is ensured, thereby ensuring the uniformity of accumulation. The control of the accumulation thickness is guaranteed, and after a certain amount of accumulation, the accumulated materials are transported forward as a whole;

[0045] In the second step, during the uniform unloading process, the moving speed of the conveying steel belt 5 can be adjusted by controlling the rotating speed of the main driving motor 1, thereby ensuring the control of the accumulation thickness and ensuring that the entire material bin is fully accumulated;

[0046] The third step is to pile up the materials inside the stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com