Self-circulation energy saving device of critical particle size for separating tailing sand bed loads from suspended loads

An energy-saving device and tailings sand technology, applied in hydraulic models, etc., can solve the problems that other rivers cannot be used, and achieve the effect of low price and convenient purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

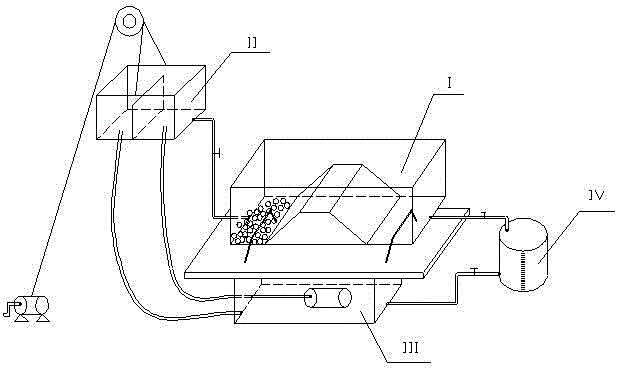

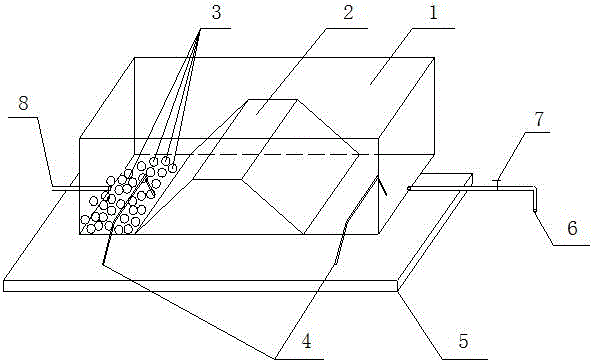

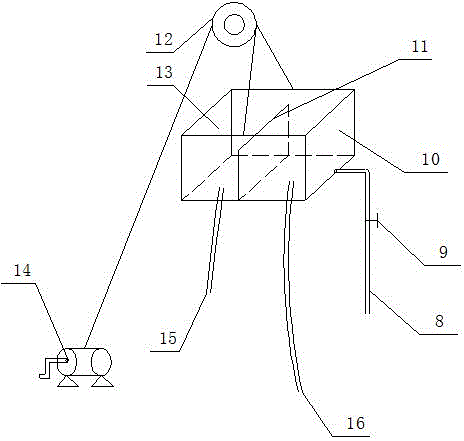

[0036] A self-circulation energy-saving device for dividing the critical particle size of tailings sand moving matter and suspended matter, including a simulated tailings starting system I, a water head control system II, a water circulation system III, and a flow measurement device IV; the simulated tailings starting system I is placed on the water circulation system III through the lifting bracket 4 and the base 5 to reduce the space occupied by the equipment; the water head control system II is connected to the simulated tailings starting system I through the model box water supply pipe 8, and is fed through the water head tank The pipe 16 and the return pipe 15 of the overflow tank are connected with the water circulation system III, and can move up and down in the vertical direction at the same time, and the moving range is from the horizontal position of the model box to 2m in the vertical direction; And the circulation return pipe 19 is connected with the simulated taili...

Embodiment 2

[0050] This embodiment adopts the same device as that of Embodiment 1. Controlled compacted dry density in embodiment 1 at 1.63g / cm 3 Left and right, in view of the fact that the dam dry density of the actual tailings dam is different, this embodiment will control the median particle size d of the tailings sand particles measured in the laboratory 50 = 0.14mm unchanged, change the measured dry density value of the tailings dam, and divide the different measured dry density values into the test of dividing the critical particle size of the drift mass and the suspended mass. The specific test steps are described as follows:

[0051] 1) Lower the head water tank 10 to the same level as the model tank 1 by the manual winch 14, inject 2 / 3 of water into the circulating water tank 17, open all the brake valves 7, 9, 20, and turn on the small submersible pump 18 Trial run, check each system for faults.

[0052] 2) After the system runs smoothly, close the small submersible pump 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com