Electrical-closed decelerator accelerated life test system

An accelerated life test, reducer technology, applied in the testing of machine/structural components, machine gear/transmission mechanism testing, instruments, etc., can solve the problems of harsh working conditions, long life time, etc. The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

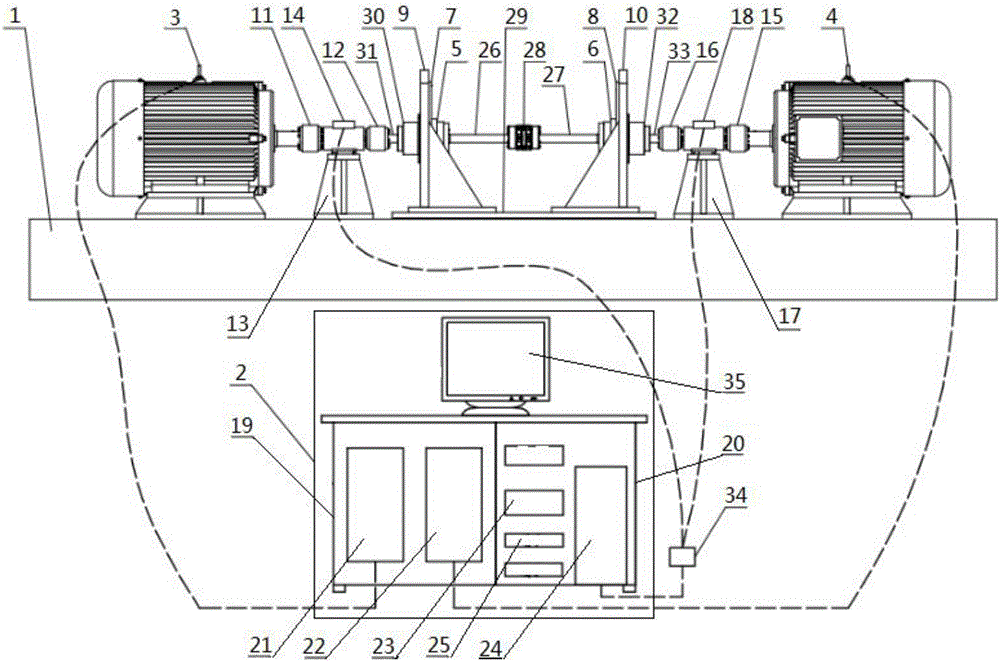

[0021] An accelerated life test system for electrically enclosed reducers, such as figure 1 As shown, the base platform 1 and the control center 2 are included, the base platform 1 is provided with a drive motor 3, and the base platform 1 is also provided with a load motor 4, a first reducer 5 and a second reducer 6, and the drive motor 3. The axis of the output shaft and the axis of the output shaft of the load motor 4 are on the same straight line. The first reducer 5 and the second reducer 6 in this embodiment are both RV reducers, and the driving motor 3 and the load motor 4 are frequency-controlled AC An asynchronous motor, the drive motor 3 is connected to the first reducer 5, the drive motor 3 is used to drive the first reducer 5, the load motor 4 is connected to the second reducer 6, the load motor 4 is used to drive the second reducer 6, and the load motor 4 is used to drive the second reducer 6. A reducer 5 is connected to the second reducer 6, and the drive motor 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com