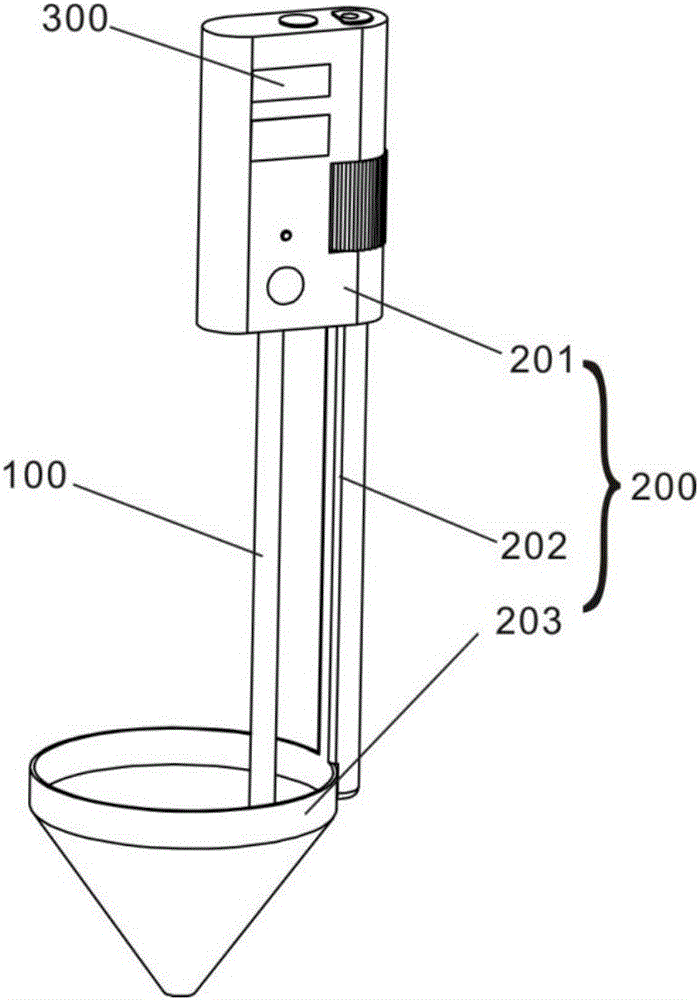

Frying oil quality fast-evaluation method and device

A frying oil, quality technology, applied in the direction of surface tension analysis, DC flow characteristic measurement, etc., can solve the problems of large amount of organic solvent, long analysis time, complicated operation, etc., to avoid interference, reduce use cost, and portable measurement equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

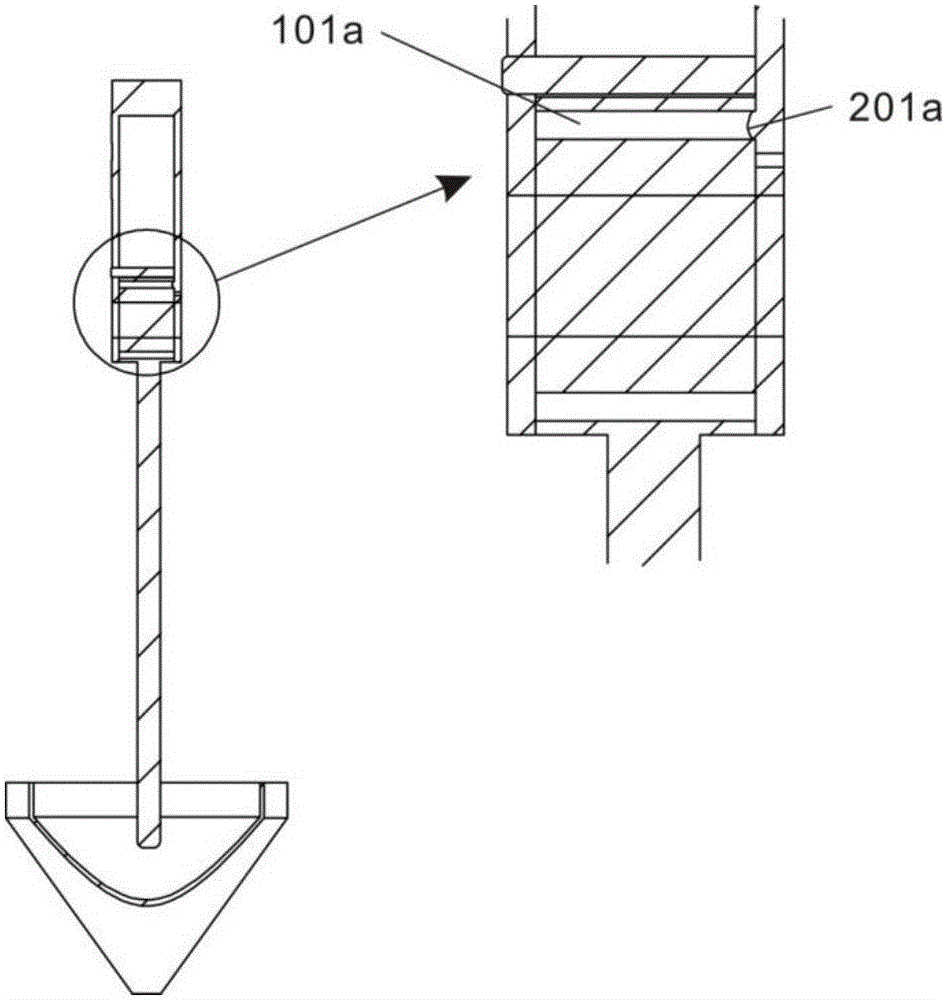

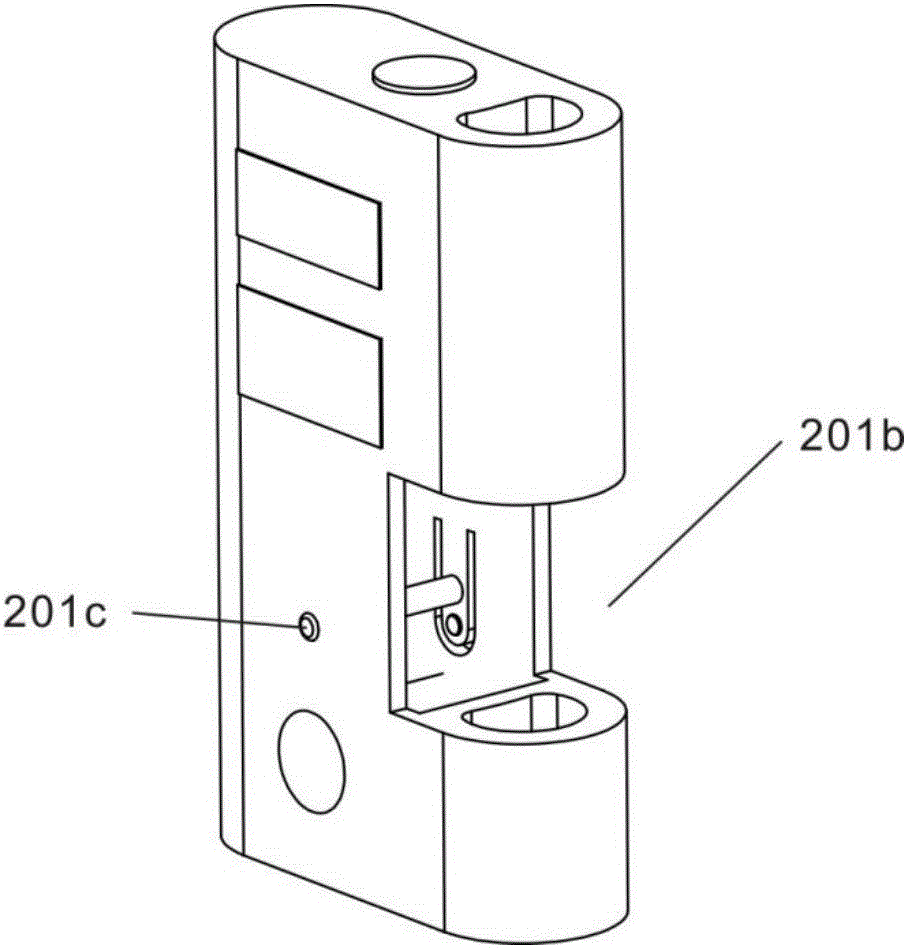

Method used

Image

Examples

Embodiment 1

[0039] Pour 5L of soybean oil into the pot, put French fries of set size and equal quality into the pot for frying, and fry for 8 hours a day for 10 days, sampling every 4 hours. Transfer the collected samples to a beaker and cool to 30°C, immerse the equipment in the oil and let it stand for 2 minutes, observe the temperature indication to ensure that the oil temperature is at 30°C. Lift the funnel until it is completely free from the oil surface and start timing. The oil in the equipment will fall naturally, keep the equipment vertical and stable, and record the total time when the oil is completely drained as the end point.

[0040] Compared with the oil type discrimination table, the falling time of the waste oil of the selected soybean oil is 60(±3)s, and the oil sample obtained after frying for 48 hours, the measured falling time at 30°C is 65s, which has exceeded the limit value, and it is judged that the frying time is 60 seconds. Frying oil should be discarded.

[0041...

Embodiment 2

[0043] Use 5L of palm oil to fry chicken nuggets continuously, heating to 182.5°C and maintaining 182.5±5°C. Put chicken nuggets of set size and equal quality into the pan for frying, frying for 8 hours a day for 6 days, and sampling every 4 hours. Transfer the collected samples to a beaker to cool to room temperature, and control the oil temperature to maintain at 30°C, immerse the equipment in the oil and let it stand for 2min, observe the temperature indication to ensure that the oil temperature is at 30°C. Lift the funnel until it is completely free from the oil surface and start timing. The oil in the equipment will fall naturally, keep the equipment vertical and stable, and record the total time when the oil is completely drained as the end point.

[0044] Compared with the oil type discrimination table, the falling time of the waste oil of the selected palm oil is 68(±3)s.

[0045] The oil sample was obtained after frying for 12 hours, and the falling time at 30°C was ...

Embodiment 3

[0049] Transfer commercially available blended oil to a beaker, and keep the oil temperature at 30°C. Immerse the equipment in the oil and let it stand for 1min. Observe the temperature reading to ensure that the temperature is kept at 30°C. Lift the funnel until it is completely free from the oil surface and start timing. The oil in the equipment will fall naturally, keep the equipment vertical and stable, and record the total time when the oil is completely drained as the end point.

[0050] Use 5L of the blended oil to fry fish fillets continuously, heat to 182.5°C and maintain 182.5±5°C. Fish fillets with a set size and equal quality were put into a pan for frying, and they were fried for 8 hours a day for 10 days, and samples were taken every 4 hours. Transfer the collected samples to a beaker to cool to room temperature, and control the oil temperature to maintain at 30°C, immerse the equipment in the oil and let it stand for 1min, observe the temperature indication to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com