Visual observation device for dissolution and separation of trace soluble impurities in cryogenic liquid

A cryogenic liquid, dissolution and separation technology, applied in the direction of measuring devices, analytical materials, thermal analysis of materials, etc., can solve the problems of visual observation of impurity crystal grain precipitation and accumulation growth characteristics, etc., to achieve convenient and reliable piping system design, Easy to test and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

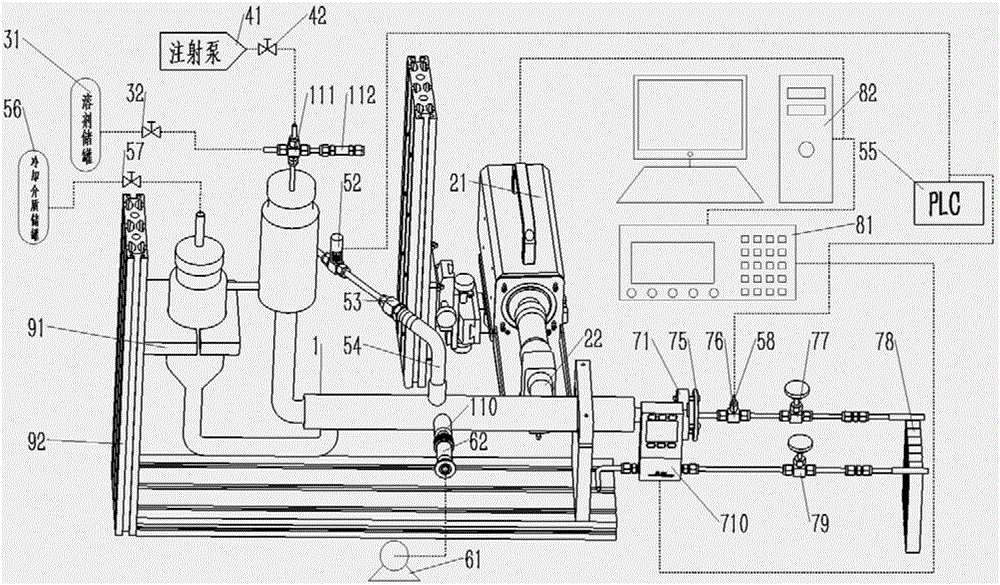

[0034] The observation system includes an integrated glass test unit 1, a high-speed microscopic camera unit 2, a cryogenic solvent filling unit 3, a soluble impurity filling unit 4, a cooling medium temperature measurement and control unit 5, a vacuum unit 6, and a gasification discharge pipe Road unit 7 is used to study the characteristics of the dissolution of soluble impurities in various low-temperature liquids, the supercooled precipitation of impurity grains, and the accumulation and growth of impurity grains.

[0035] Such as figure 1 As shown, the integrated glass test unit 1 is installed on the aluminum profile plate 92 through two hoops 91 in the horizontal and vertical directions, and the high-speed camera 21 equipped with the microscope lens 22 is also installed on the aluminum profile plate 92 through the three-dimensional direction adjustable support. profile plate.

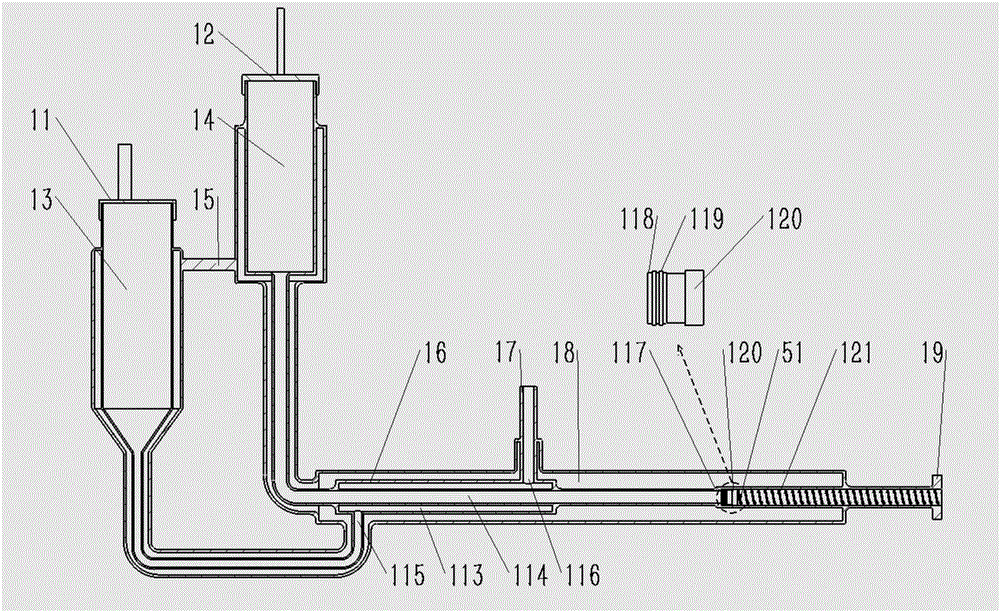

[0036] Such as figure 1 with figure 2 As shown, the outermost layer of the integrated glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com