RFID-based key point supervision method and system for vegetable production process

A production process and key point technology, which is applied in the field of RFID-based supervision of key points in the vegetable production process, can solve problems such as low accuracy, low safety level, and poor traceability, so as to improve quality safety level, correctness and authenticity Accurate, efficient and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

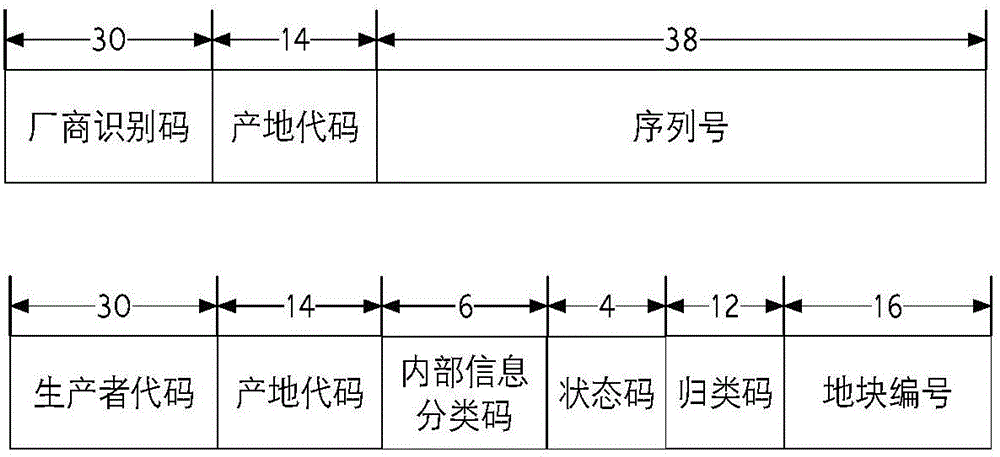

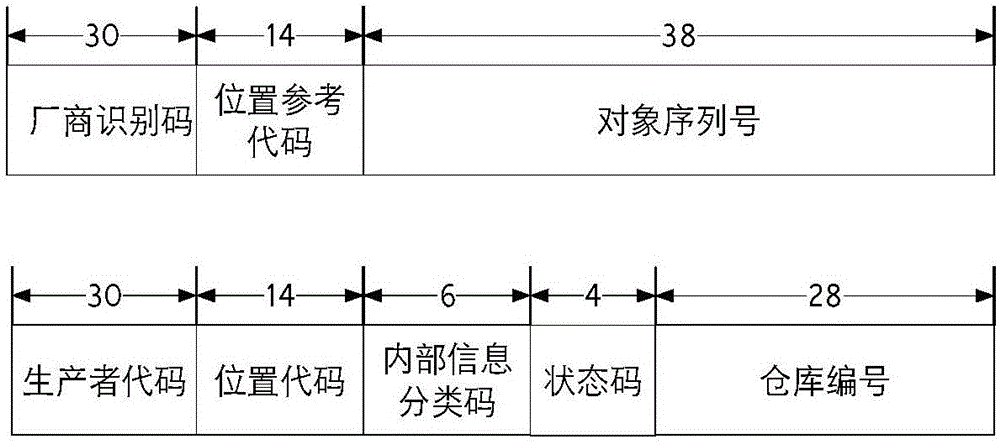

[0051] S1, based on the design of agricultural product production management identification system

[0052] S11 key object identification

[0053] Use the EPC code to code the related objects in the vegetable production process, so that they can be managed through a unified identification. These objects include: planting plots / working areas, material / planting product warehouses, staff, non-recyclable equipment / materials, recyclable equipment / materials.

[0054] (1) Planting plot identification

[0055] In this paper, EPC-96 is used to code the land parcels, and the specific coding scheme adopts the Global Location Reference Number (SGLN). SGLN consists of Header, Filter Value, Partition, Company Prefix and Individual Asset Reference. The value of the header is 00110100, and the filter value can be 000 (indicating "other" type).

[0056]

[0057] Table 1GIAI-96 encoding format

[0058]

[0059] Table 2 SGLN-96 partition value table

[0060] As shown in Table 1 and T...

Embodiment 2

[0146] The specific steps of using the present invention to supervise the vegetable production process are as follows:

[0147] (1) Production site equipment deployment. Since only the "access control" type RFID system or EPC tags need to be set at key positions, the readable distance of EPC tags does not need to be too large, so Class 1Gen2 EPC tags (or Gen2 for short) are selected. Gen2 is an open standard, and the corresponding parameters are shown in Table 10. Small size, large storage capacity and special password can be set, the application of Gen2 can ensure the compatibility between different manufacturers, and ensure the coordination between different components (including hardware parts) in the EPCglobal network system.

[0148]

[0149] Table 10 EPC Class 1Gen2 label parameters

[0150] Such as Figure 20 Shown is the deployment diagram of the hardware equipment in the production area. RFID equipment or EPC tags are installed in each work area. Whenever a work...

Embodiment 3

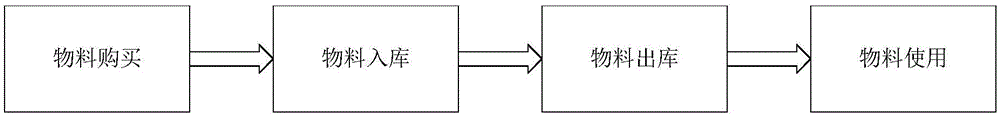

[0158] (1) Use EPC to identify key objects. Use EPC codes to code related objects in the vegetable production process (such as inputs, planting plots, staff, planting products, etc.), so that they can be managed through a unified identification. Based on the Internet of Things technology, all objects in the entire vegetable production process are managed in a unified manner.

[0159] (2) Use network video technology to monitor the production process of the plot. Cameras are installed on each plot to collect videos of the vegetable production process in each plot, upload and save them on the server, and users and staff can retrieve and view them according to their geographic location.

[0160] (3) Use the EPCIS information service framework to realize the collection of event data. After the terminal reads the RFID tag, it will generate corresponding event data according to the local configuration context, embed key data into these event data formats, and use the data collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com