Bottomless paper RFID label based on conductive ink printed antenna

A technology of RFID tags and conductive inks, applied in the field of labels, can solve the problems of high cost of raw materials and equipment, waste of self-adhesive label bottom paper, large production investment, etc., so as to save raw material costs, promote popularization and use, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

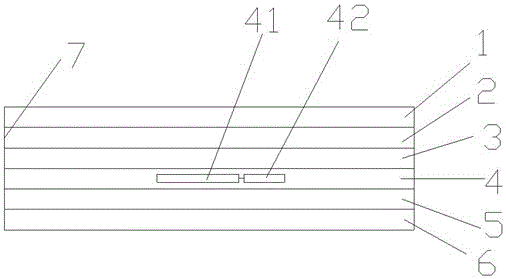

[0031] Such as figure 1 As shown, a kind of bottomless RFID label based on conductive ink printed antenna provided by the present invention includes a release agent coating 1, an anti-seepage layer 2, a thermal paper layer 3, an antenna 41 printed by conductive ink and an RFID label. The RFID label layer 4, the bottom layer 5, the glue layer 6, and the tear line 7 composed of chips 42, wherein the RFID label layer 4 is bonded between the lower surface of the thermal paper layer 3 and the upper surface of the bottom layer 5, and the glue layer 6 Coated on the lower surface of the bottom layer 5, the anti-seepage layer 2 is coated on the upper surface of the thermal paper layer 3, the release agent coating 1 is coated on the anti-seepage layer 2, and the tear line 7 is processed on each adjacent Between two linerless RFID labels.

[0032] The bottom layer 5 is an insulating substrate composed of PET film. The bottom layer is used to encapsulate and fix the RFID label layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com