VCSEL laser tube core packaging method

A packaging method and laser technology, applied in the field of lasers, can solve the problems of difficult welding between ceramics and metals, unreasonable die structure, and low heat dissipation efficiency, and achieve the effects of improved heat dissipation performance, convenient maintenance, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

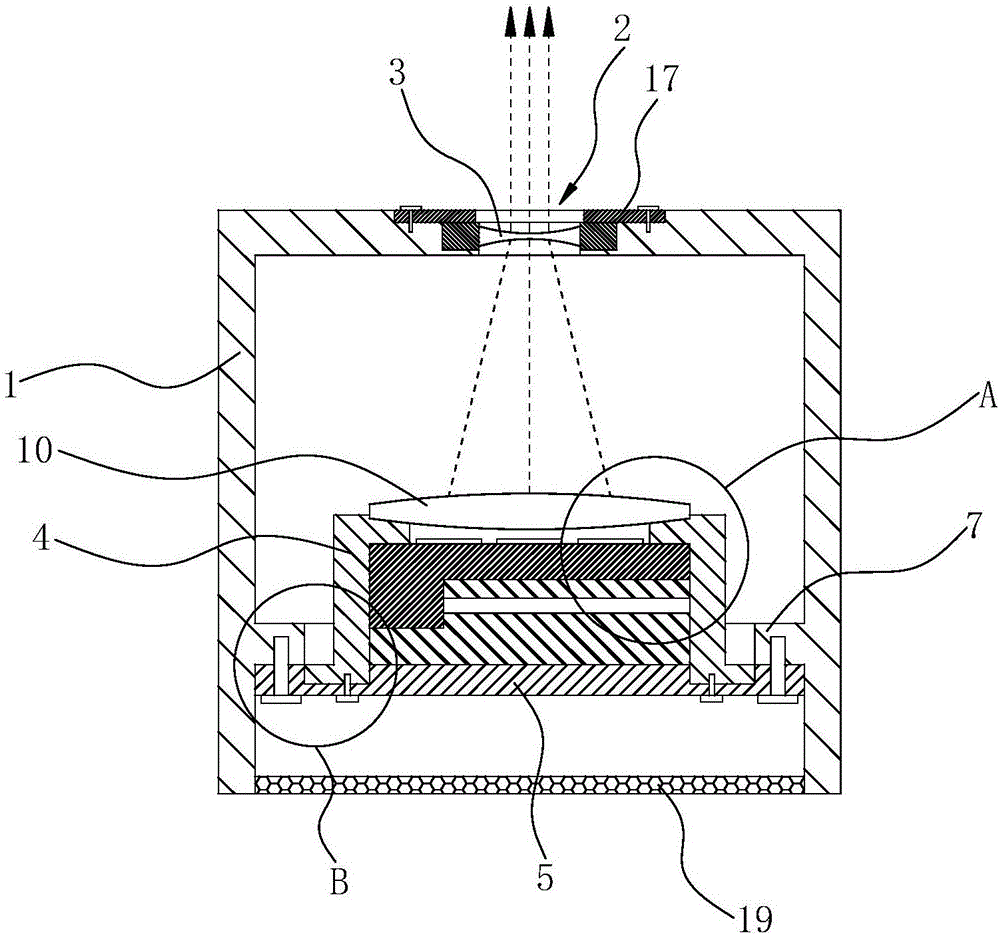

[0032] combine Figure 1-5 A VCSEL laser tube core packaging method shown, the tube core includes a tube body 1, one end of the tube body 1 is a closed end, and the other end is an open end, as figure 1 As shown in , the upper end of the pipe body 1 is a closed end, and the lower end is an open end. An injection port 2 is provided on the end surface of the closed end of the tube body 1 , and a concave lens 3 is provided in the injection port 2 .

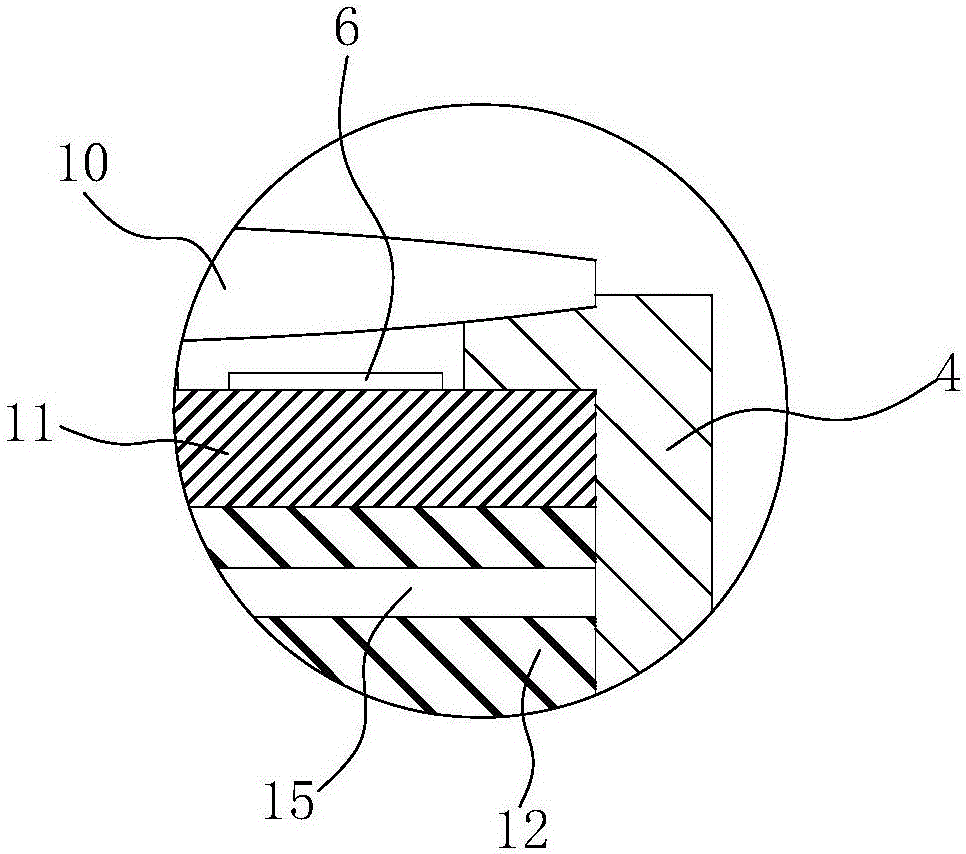

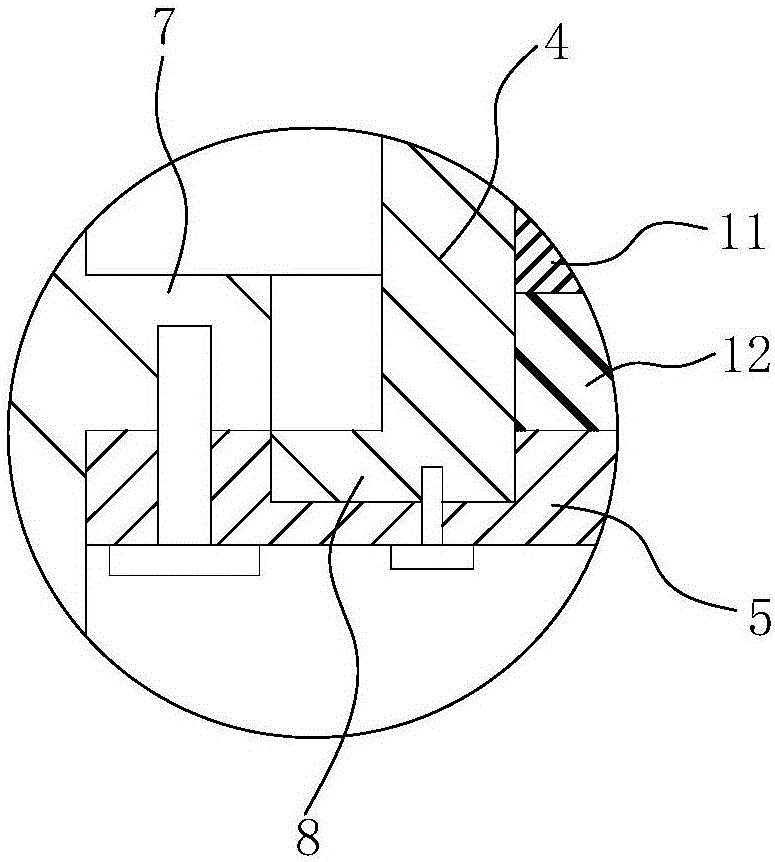

[0033] A laser emitting assembly is arranged inside the tube body 1 , and the laser emitting assembly includes a mounting cover 4 , an outer cooling plate 5 , an inner cooling plate and a VCSEL chip array 6 . The connection relationship between the outer cooling plate 5 and the pipe body 1 of the present invention is as follows: a ring-shaped resisting portion 7 is arranged on the inner wall of the pipe body 1 near the opening end, and the resisting portion 7 is formed on the inner wall of the pipe body 1 toward the pipe body. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com