An inspection robot system and method for an overhead ground wire that is barrier-free throughout the whole process

A technology for inspection robots and overhead ground wires, which is applied in the direction of overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of low obstacle clearance efficiency, low safety factor, and difficult control, so as to ensure online safety and improve The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] A full-range inspection robot for overhead ground wires and a barrier-free ground wire passage, including a full-range inspection robot and a barrier-free ground wire passage suitable for the robot;

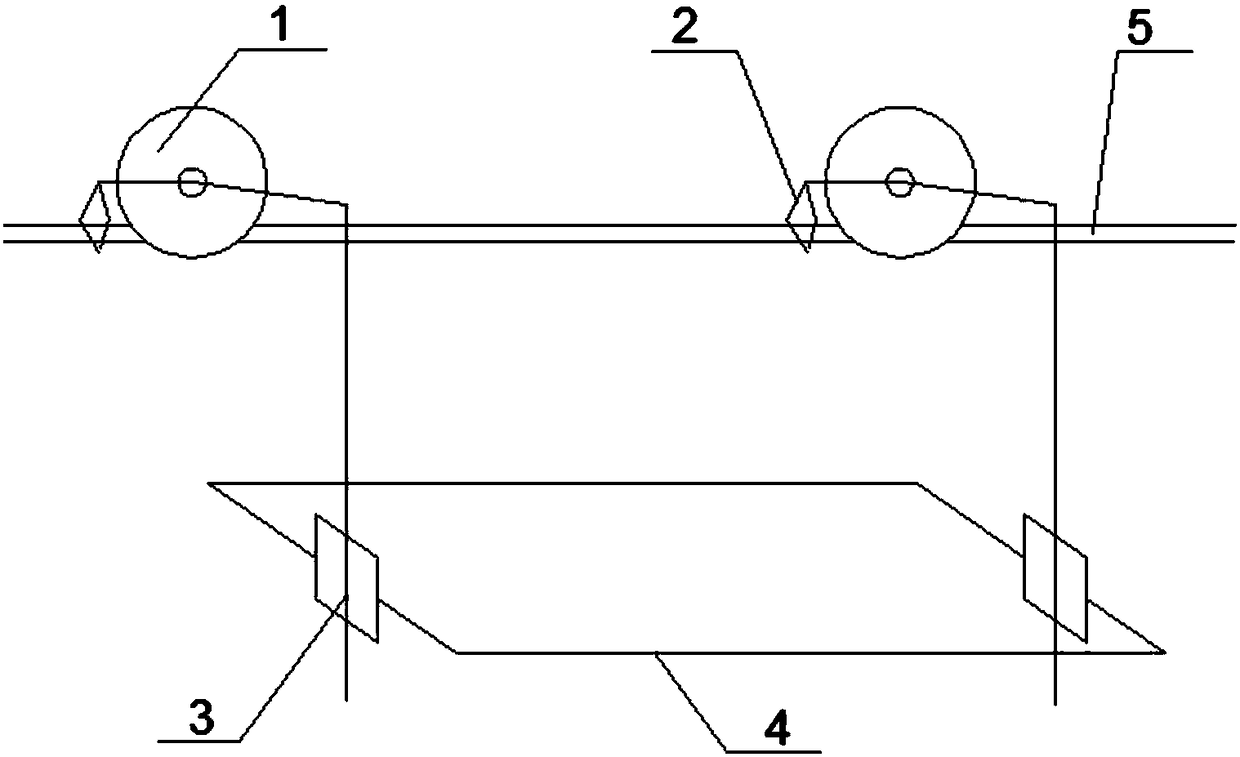

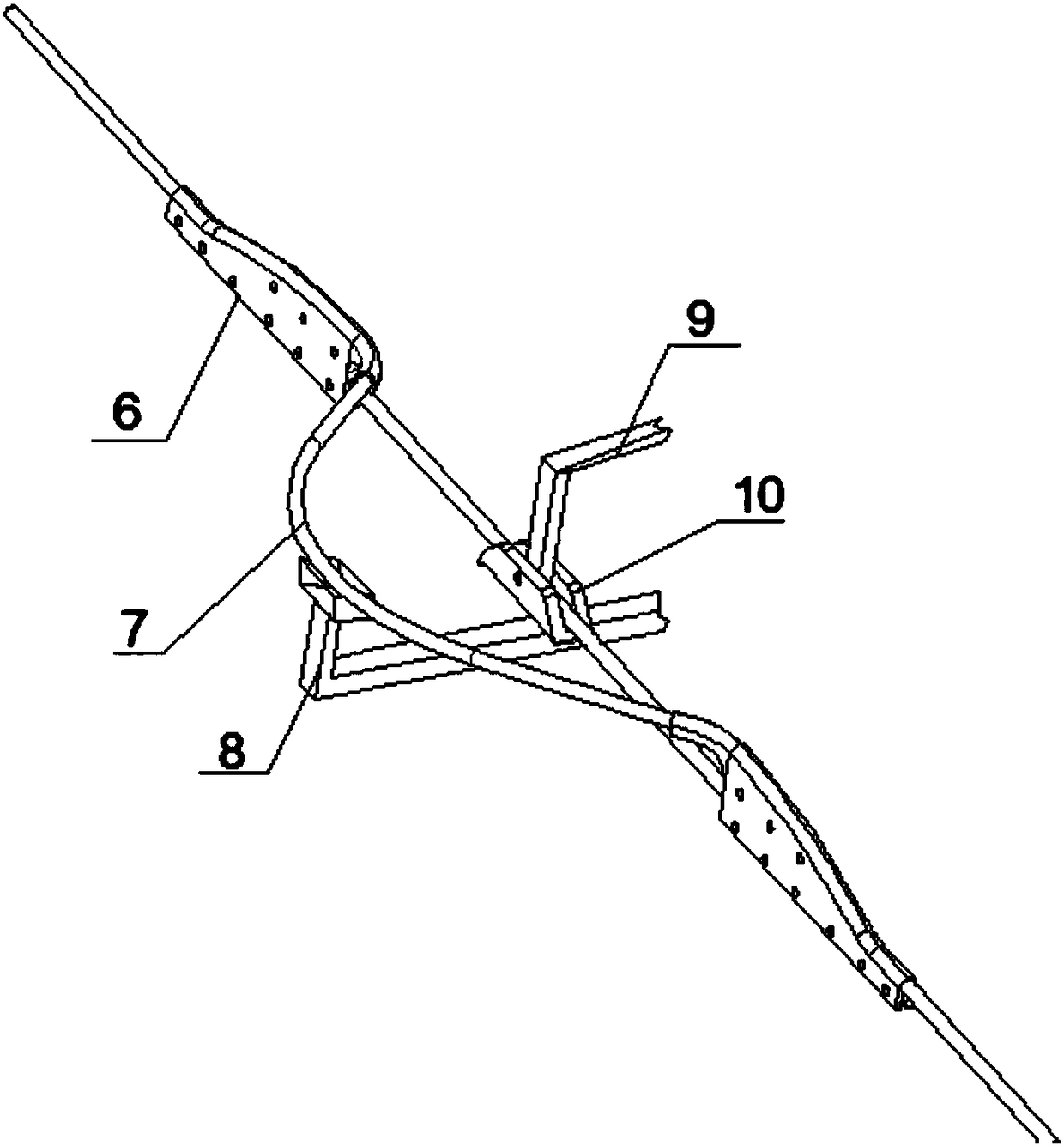

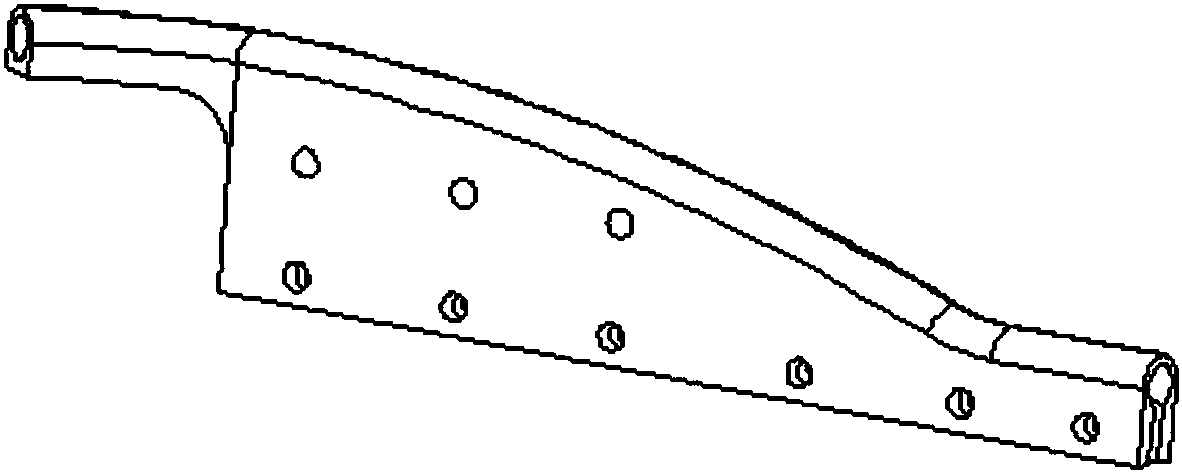

[0039] The overhead ground wire full inspection robot and the barrier-free ground wire channel adapt to each other and complement each other. The full inspection robot includes a driving wheel, a clamping wheel, a rotary joint and a frame. There are two driving wheels, which ride on the ground wire respectively; There are two clamping wheels, which are respectively installed and fixed on the front part of the driving wheel; a rotary joint is connected below each driving wheel, and the rotary joint is fixed on the frame.

[0040] The barrier-free ground passage includes the transformation of the barrier-free passage on the straight pole tower and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com