Spray tower filler for absorbing waste gas in olive leaf extract production

An olive leaf extract, spray tower technology, applied in gas treatment, chemical/physical process, chemical/physical/physical-chemical process, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

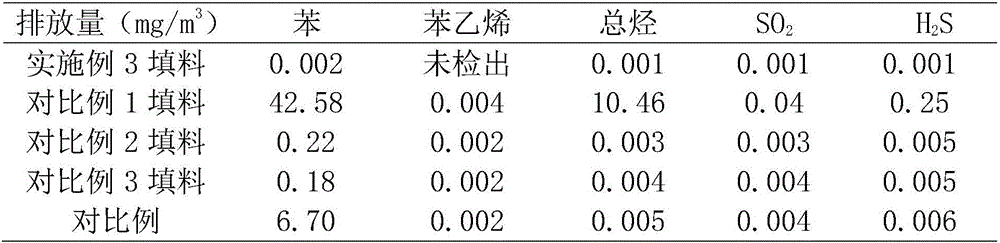

Examples

Embodiment 1

[0023] A kind of spray tower packing used for absorbing waste gas in the production of olive leaf extract is prepared through the following steps:

[0024] 1) Raw material preparation: prepare 90kg of fiber silk and 10kg of lychee skin;

[0025] 2) Processing of lychee skin:

[0026] ① Grinding treatment: After crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with a high-speed shear emulsifier for 10 minutes, and the speed is 12000r / min, and then use high-pressure micro-jet ultrafine grinding equipment at 25 ℃, the treatment pressure is 50MPa, and the number of treatments is 2-3 times to obtain a paste slurry;

[0027] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.0Mpa, and the pressure holding time is maintained at 200s;

[0028] ③Decoction: Add the material obtained in step ② into pure water of equal weight and decoct twice, each time for 1 hour, to obtain the extrac...

Embodiment 2

[0033] A kind of spray tower packing used for absorbing waste gas in the production of olive leaf extract is prepared through the following steps:

[0034] 1) Raw material preparation: prepare 92kg of fiber filaments and 8kg of lychee skin;

[0035] 2) Processing of lychee skin:

[0036] ① Grinding treatment: After crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with a high-speed shear emulsifier for 20 minutes, and the speed is 8000r / min, and then use high-pressure micro-jet ultrafine grinding equipment at 25 ℃, the treatment pressure is 55MPa, and the number of treatments is 2-3 times to obtain a paste slurry;

[0037] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the holding time is maintained at 150s;

[0038] ③Decoction: Add the material obtained in step ② into pure water of equal weight and decoct twice, each time for 1 hour, to obtain the extract, fil...

Embodiment 3

[0043] A kind of spray tower packing used for absorbing waste gas in the production of olive leaf extract is prepared through the following steps:

[0044] 1) Raw material preparation: prepare 95kg of fiber filaments and 5kg of lychee skin;

[0045] 2) Processing of lychee skin:

[0046] ① Grinding treatment: after crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with a high-speed shear emulsifier for 15 minutes, and the speed is 10000r / min, and then use high-pressure micro-jet ultrafine grinding equipment at 25 ℃, the treatment pressure is 60MPa, and the number of treatments is 2-3 times to obtain a paste slurry;

[0047] ②Steam explosion: put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the holding time is maintained at 180s;

[0048] ③Decoction: Add the material obtained in step ② into pure water of equal weight and decoct twice, each time for 1 hour, to obtain the extract, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com