A kind of preparation method of wood nanofiber

A nanofiber and wood fiber technology, which is applied to artificial filaments made of cellulose derivatives, pulping with organic solvents, pulping with acid salts/acid anhydrides, etc., can solve the problem of low catalytic activity of TEMPO and easy generation of nanofibers. Agglomeration, uneven distribution of wood nanofibers diameter, etc., to achieve the effect of low degree of mutual aggregation, good separation treatment, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

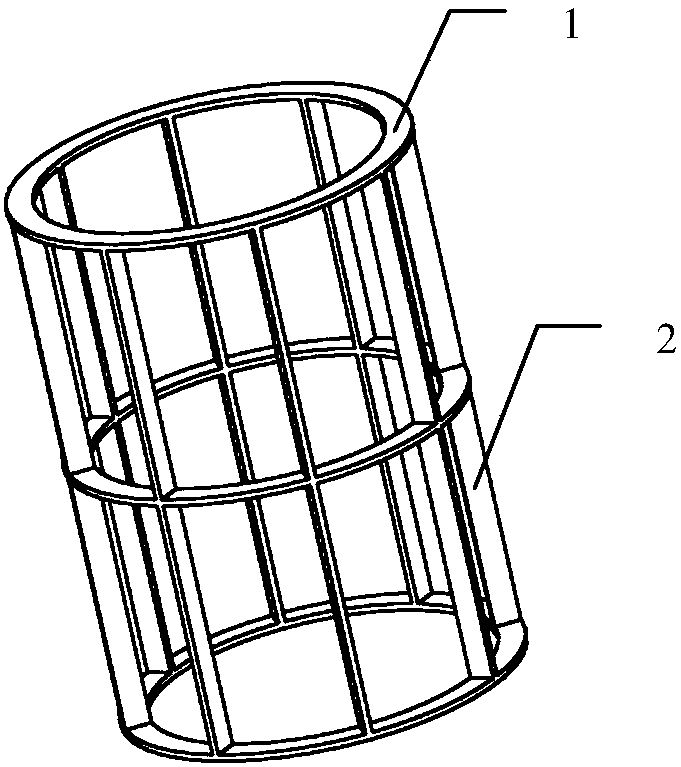

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] refer to figure 1 , a preferred embodiment of the present invention provides a method for preparing wood nanofibers, comprising the steps of:

[0031] S1. Using a mixture of sulfurous acid and acidic sulfite as a cooking agent to cook wood fibers to obtain pulp;

[0032]S2. Weigh the pulp and the benzene alcohol solution according to the mass ratio of the pulp and the benzene alcohol solution at a ratio of 1:80, mix the two under agitation, and extract at a temperature of 90°C for 8 hours to obtain the extracted wood fiber;

[0033] S3. prepare the sodium chlorite solution that mass concentration is 1.5%, and adjust its pH value to 4~5 with glacial acetic acid, add some polyethylene friction blocks in the sodium chlorite solution, the volume of the added polyethylene friction blocks accounts for 1 / 3rd of the volume of sodium chlorit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com