Detachable assembly type splicing node for reinforced concrete columns

A reinforced concrete column and reinforced concrete technology, which is applied in the direction of construction and building construction, can solve the problems of low degree of industrialization, extensive design and construction, large resource and energy consumption, etc., to reduce on-site welding work and formwork work, and repair And the cost of replacement is small, and the effect of ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

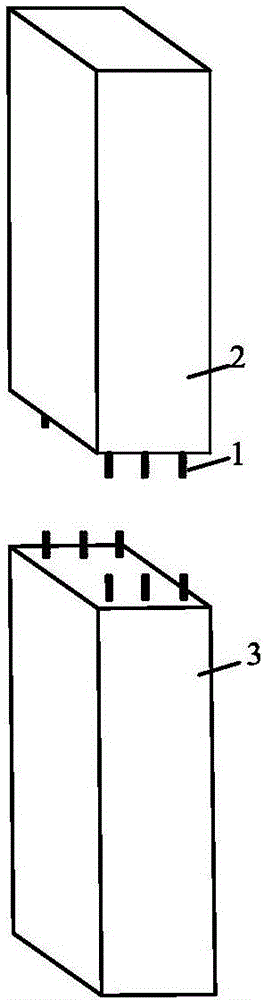

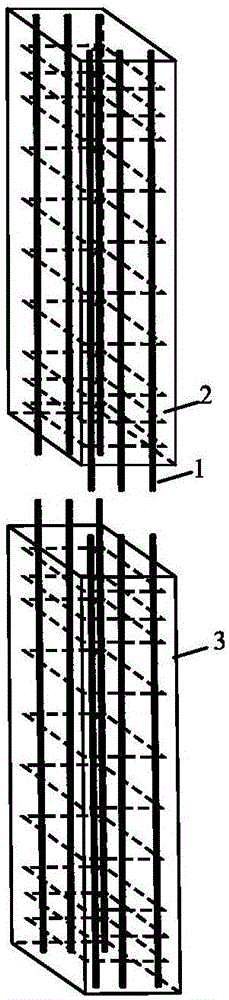

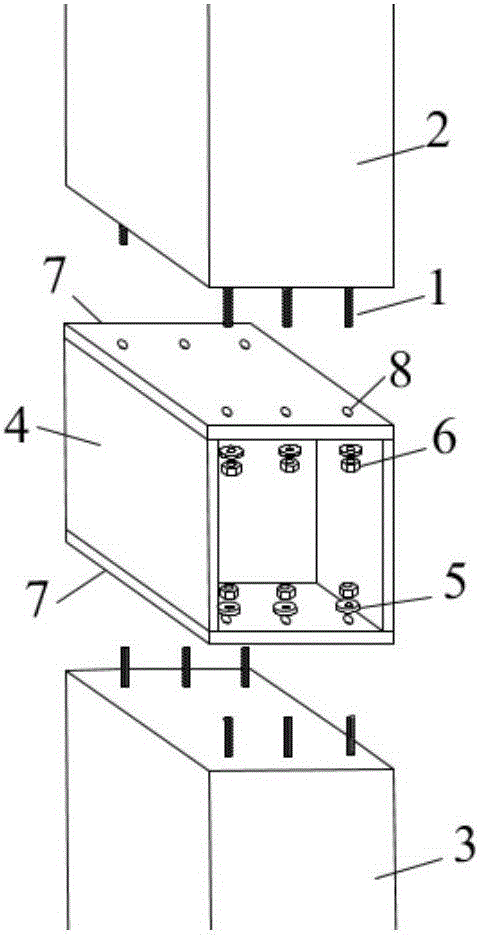

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific installation methods. The main components of the structural system include extended longitudinal reinforcement 1, reinforced concrete upper column 2, reinforced concrete lower column 3, H-shaped steel 4, 2 steel plates 7 with bolt holes and 2 sealing plates 10 with grouting holes. The construction sequence of the structure of the present invention As follows:

[0030] 1. In addition to on-site extended longitudinal reinforcement 1, use gasket 5 and nut 6 to tighten on steel plate 7 with bolt holes, and both sides of H-shaped steel 4 are sealed with steel sealing plates 10 with grouting holes, and then grouting through grouting holes 11 In addition, all components are prefabricated in the factory, and the size and spacing of bolt holes 8 reserved on the extended longitudinal bars 1 and steel connectors should meet the structural requirements. The rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com