Oxygen-enriched molten pool melting furnace

A technology for smelting and smelting zone in an oxygen-enriched molten pool, applied in furnaces, charge materials, crucible furnaces, etc., can solve problems such as large cooling energy loss, large water consumption, and easily damaged water jackets, achieve a high degree of mechanical automation, and reduce consumption. , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

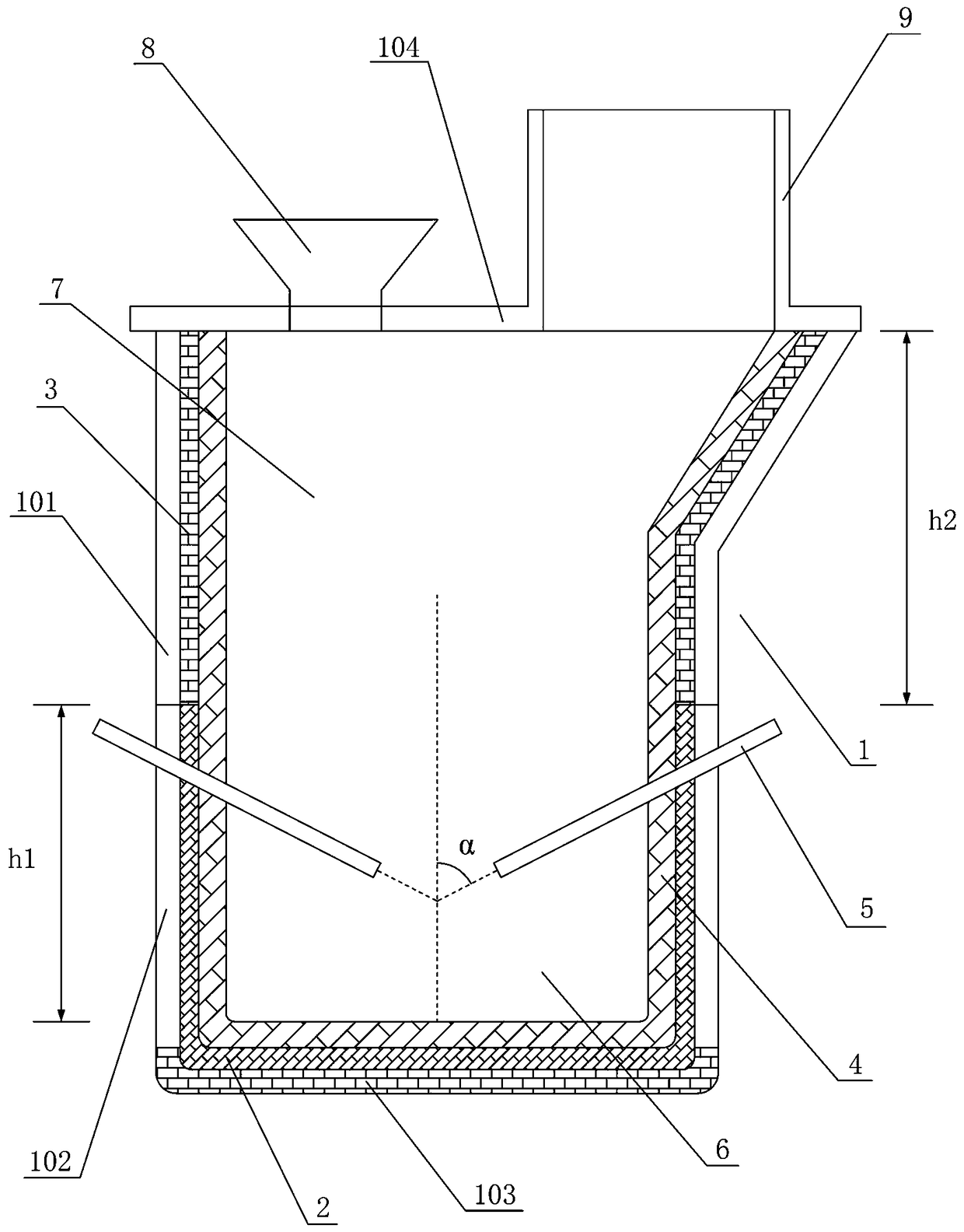

[0028] An embodiment of the oxygen-enriched molten pool smelting furnace of the present invention, the oxygen-enriched molten pool smelting furnace is mainly used for processing various non-ferrous metal materials, such as copper, lead, zinc, nickel, tin, bismuth, indium and gold and silver materials, copper, lead, zinc, tin, bismuth, nickel and other non-ferrous metals and gold, silver, platinum, palladium and other rare and precious metals are recovered through treatment. The reduction furnace is used. The structure of the oxygen-enriched molten pool melting furnace is as follows: figure 1 shown by figure 1 Visible, it mainly comprises furnace body 1, and the vertical cross-section of this furnace body 1 is rectangular or circular, has furnace chamber in furnace body 1, and the top of furnace body 1 is provided with furnace cover 104, and furnace cover 104 is provided with feeding port. 8 and straight up flue 9. The furnace wall of the furnace body 1 is divided into two p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com