Laying method for lining of reduction furnace

A reduction furnace and lining technology, which is applied in the field of lead smelting, can solve the problems of short service life of refractory bricks, many spray gun specifications, and difficult replacement, and achieve the effects of avoiding shutdown, high economic benefits, and reducing the probability of reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment the present invention is described in further detail:

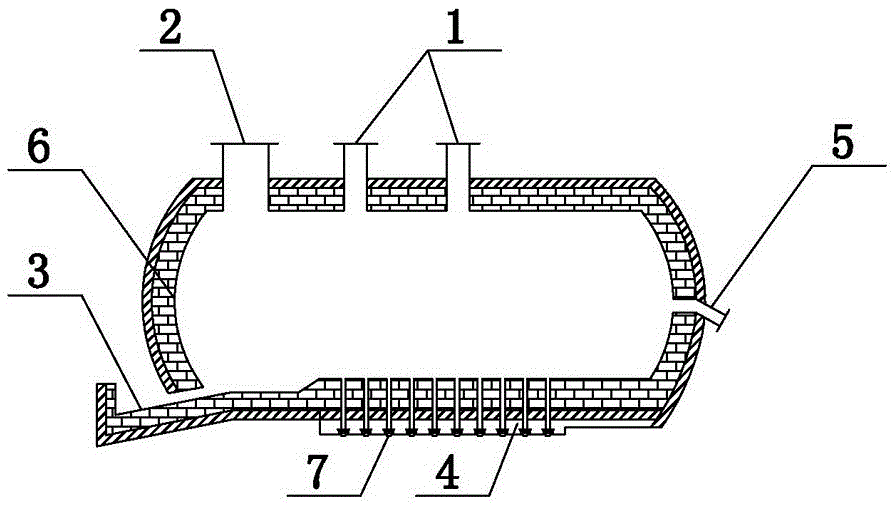

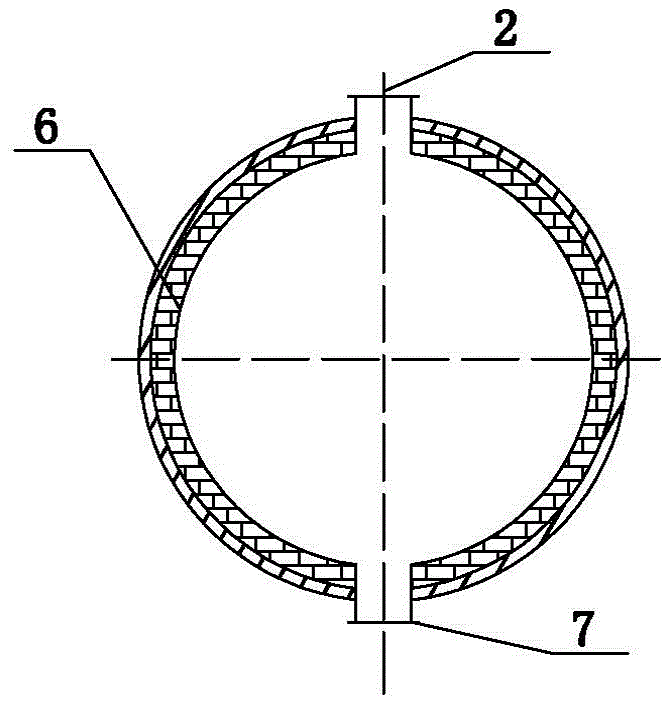

[0019] like figure 1 and figure 2 As shown, a method for building the inner lining of a reduction furnace. The reduction furnace includes a feed port 1, a flue port 2, a siphon passage 3, a spray gun area 4, a slag outlet 5, and a lining 6. The reduction furnace is a horizontal round Cylindrical, there are two feeding ports 1 above the top of the reduction furnace, the flue port 2 and the siphon channel 3 are on the same side of the reduction furnace, the flue port 2 is on the top of the reduction furnace, and the siphon channel 3 is at the lower left of the reduction furnace , the slag outlet 5 is on the other side of the reduction furnace, the spray gun area 4 at the bottom of the reduction furnace is provided with ten spray guns 7, and the spray guns 7 are arranged in a single row in the spray gun area 4, and the bottom of the reduction furnace is The inner lining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com