Preparation method of sintered neodymium-iron-boron magnet surface diffusion layer

A surface diffusion layer, neodymium iron boron technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of being unable to get rid of the dependence of rare earth elements, so as to improve the coercivity, ensure the diffusion effect, reduce the The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Cut the sintered NdFeB magnet with the brand name N35 and 33% rare earth mass percentage into a cylindrical sheet of Φ20mm×4mm; use the magnetron sputtering method to sputter the Cu-Al target with 50% Al mass percentage The power is 50W, the working pressure is 0.8Pa, the Ar gas flow is 20sccm, the time is 4.5h, and the temperature is room temperature; the surface deposition thickness is about 1 μm; -3 Pa, 1000°C for 3h, 700°C for 2h; then at 450°C, vacuum 10 -3 The surface diffusion layer of the sintered NdFeB magnet was obtained by treating for 5 hours under the condition of Pa.

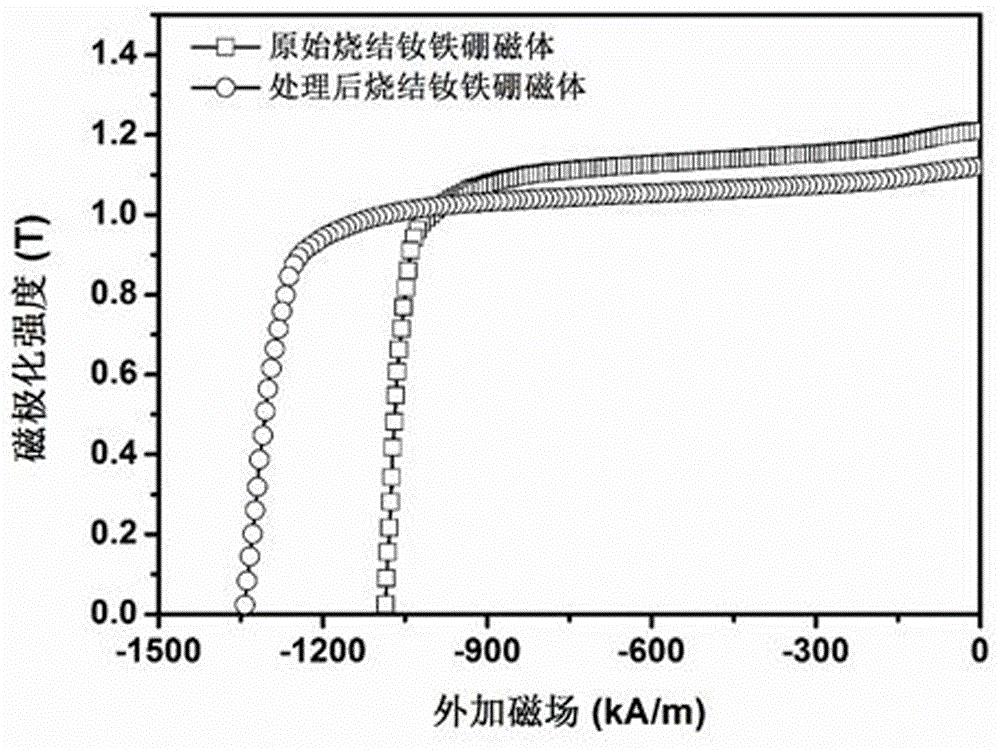

[0018] From figure 1 It can be seen that the coercive force (Hcj) of the Cu-Al surface diffusion layer of the sintered NdFeB magnet has been greatly improved compared with the original sintered NdFeB magnet, from 1085kA / m to 1370kA / m (300K) , and the reduction in remanence is not obvious, from 1.20T to 1.12T (300K).

Embodiment 2

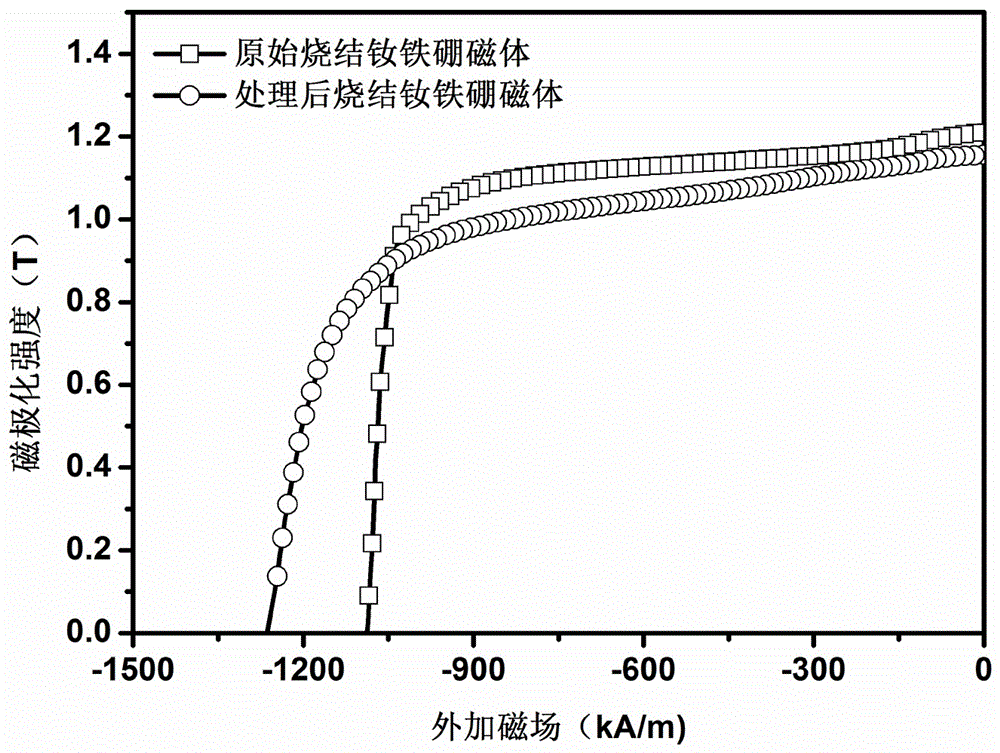

[0020] Cut the sintered NdFeB magnet with the brand name N35 and 33% rare earth mass percentage into a cylindrical sheet of Φ20mm×4mm; use the magnetron sputtering method to sputter the Cu-Zn target with 30% Zn mass percentage The power is 100W, the working pressure is 0.5Pa, the Ar gas flow is 25sccm, the time is 2h, and the temperature is room temperature; -4 Pa, 900°C for 5h, 650°C for 3h; then at 500°C, vacuum 10 -3 Treat for 2 hours under Pa condition to get the surface diffusion layer of sintered NdFeB magnet. From figure 2 It can be seen that the coercive force (Hcj) of the Cu-Zn surface diffusion layer of the sintered NdFeB magnet has been greatly improved compared with the original sintered NdFeB magnet, from 1085kA / m to 1264kA / m (300K) , and the reduction in remanence is not obvious, from 1.20T to 1.15T (300K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com