Crop special-purposed composite fertilizer application method

A technology of compound fertilizer and application method, which is applied in the field of agriculture, can solve problems such as insufficient potassium fertilizer usage and low fertilizer utilization rate, and achieve the effects of saving costs, realizing high-efficiency utilization, and maintaining the continuous supply capacity of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

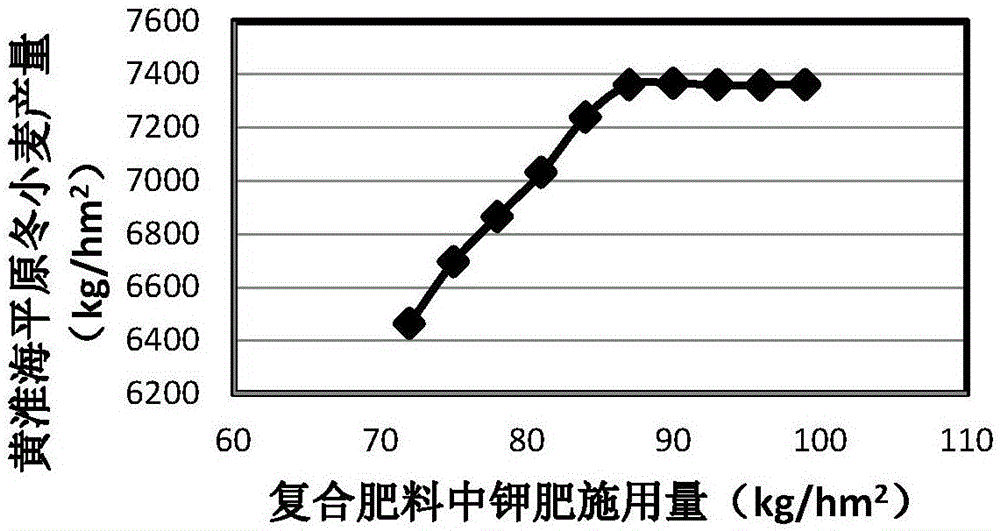

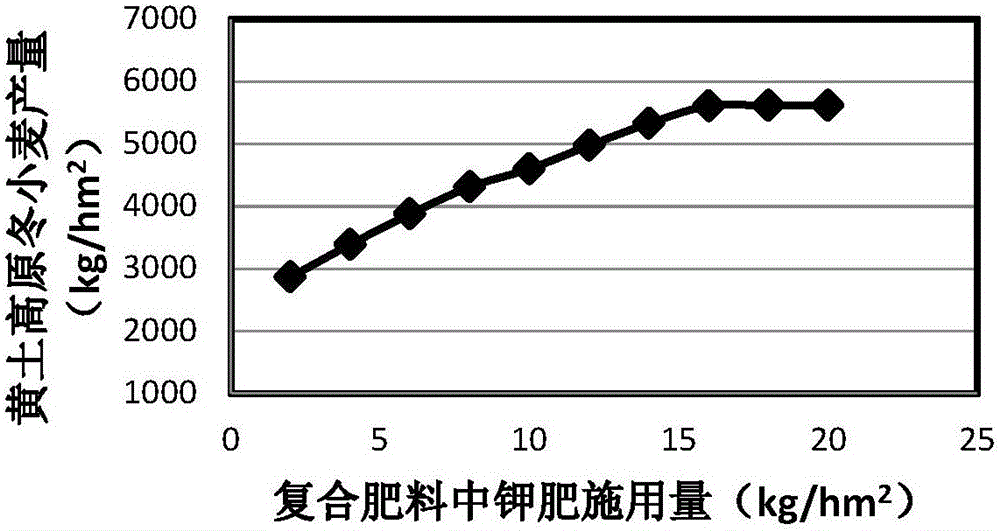

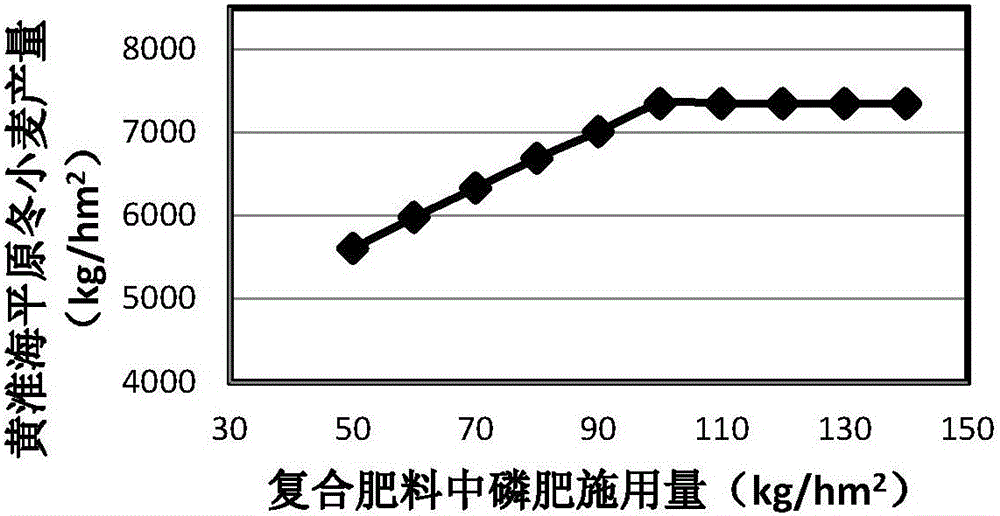

[0041] In this example, winter wheat in the Huang-Huai-Hai Plain and the Loess Plateau are taken as examples. According to the local environmental conditions and the statistical data of local winter wheat production in 2005-2010, the target yields of winter wheat in the Huang-Huai-Hai Plain and the Loess Plateau are 7355kg / hm respectively. 2 and 5614kg / hm 2 , the potassium requirements of 100kg grain are 2.69kg and 2.63kg respectively.

[0042] The straw yields of winter wheat in the Huang-Huai-Hai Plain and the actual field survey of the Loess Plateau were 7804kg / hm 2 and 7121kg / hm 2 , the straw returning rates were 71.5% and 100%, respectively, and the mass of potassium in 100kg straw was 1.92kg and 1.71kg respectively.

[0043] The available potassium content in the Huang-Huai-Hai Plain and the Loess Plateau is 104 mg / kg and 167 mg / kg. Based on the 100 mg / kg soil available potassium, the correction coefficients for potassium fertilizer application in the Huang-Huai-Hai wi...

Embodiment 2

[0085] In this embodiment, taking spring sown corn in Northeast China and summer sown corn in Huanghuaihai Plain as examples, according to the local environmental conditions and the statistical data of local corn production in 2005-2010, the target yields of spring sown corn in Northeast China and summer sown corn in Huanghuaihai Plain are respectively 9772kg / hm 2 and 9426kg / hm 2 , the potassium requirements of 100kg grain are 1.69kg and 1.80kg respectively.

[0086] The straw yields of spring-sown corn in Northeast China and summer-sown corn in Huanghuai-Hai Plain are 9401kg / hm 2 and 9068kg / hm 2 . The straw return rates were 36.7% and 85.0%. The masses of potassium in 100kg of straw are 1.60kg and 1.68kg respectively.

[0087] The content of available potassium in spring-sown corn in Northeast China and summer-sown corn in Huang-Huai-Hai Plain is 133 mg / kg and 104 mg / kg. Based on soil available potassium 100 mg / kg, the correction coefficients of potassium fertilizer app...

Embodiment 3

[0130] In this example, the late rice in the double-single-cropping rice area in the Jiangnan hilly plain is taken as an example. According to the local environmental conditions and the statistical data of local rice production in 2005-2010, the target output of late rice in the double-single-cropping rice area in the Jiangnan hilly plain is 7790kg / hm 2 , The potassium requirement of 100kg grain is 2.66kg.

[0131] The straw yield of the late rice investigation in the double-single cropping rice area in the Jiangnan hilly plain is 7194kg / hm 2 , the rate of straw returning to the field is 68.7%, and the mass of potassium in 100kg of straw is 2.66kg.

[0132] The content of available potassium in the double-single rice-cropping area of the Jiangnan hilly plain is 77.0 mg / kg. Based on the soil available potassium 100 mg / kg, the correction coefficient of potassium fertilizer application in the double-single rice-growing area of the Jiangnan hilly plain is 1.30.

[0133] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com