Non-precious metal catalyst for preparing liquefied petroleum gas and preparation method of non-precious metal catalyst for preparing liquefied petroleum gas

A technology of liquefied petroleum gas and non-precious metal, which is applied in the field of non-precious metal catalyst for dimethyl ether conversion and its preparation, can solve the problem of high preparation cost, and achieve the effects of reducing the generation of by-products, improving the selectivity, and slowing down carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 12.3871gNi(NO 3 ) 2 . 6H 2 O, 9.5043gCu(NO 3 ) 2 . 3H 2 O, add 70mL deionized water, stir to dissolve, and weigh 50g SiO 2 / Al 2 o 3 The Hβ molecular sieve with a molar ratio of 25 was placed in a beaker, and the prepared solution was slowly added into the beaker while stirring continuously. Stir and impregnate in a constant temperature water bath at 50°C for 3h, then introduce ultrasonic impregnation for 3h, the ultrasonic frequency is 22kHz, put the impregnated catalyst in an oven, dry at 120°C for 4h, and finally roast at 450°C for 4h. 20-40 mesh.

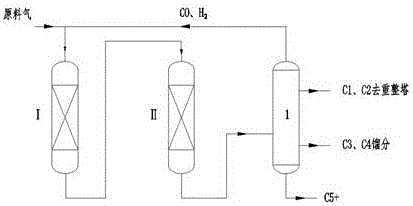

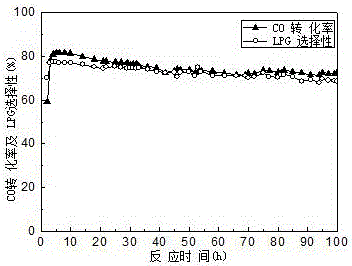

[0042] The activity of the catalyst was evaluated by using two-stage reactors connected in series. Catalyst for industrial methanol synthesis and γ-Al 2 o 3 Take 20-40 mesh by crushing and sieving, weigh 0.5g each, mix evenly and load it into the first-stage reactor; weigh 1g catalyst and load it into the second-stage reactor. The first stage catalyst uses Cu-Zn-Al 2 o 3 / γ-Al 2 o 3 Mixed catalyst,...

Embodiment 2

[0045] The specific implementation process is roughly the same as that of Embodiment 1, except that the ultrasonic frequency is 32kHz.

[0046] The reaction result in this state is recorded as Cat2, see Table 1 and Table 2 for details.

Embodiment 3

[0048] The specific implementation process is roughly the same as that of Embodiment 1, except that the ultrasonic frequency is 42kHz.

[0049] The reaction result in this state is recorded as Cat3, see Table 1 and Table 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com