Steel wire rope lifting bar and moderate-thickness plate mechanical sizing equipment and method

A steel wire rope and sizing technology, applied in the field of steel rolling, can solve the problems of low quality grade, product quality, performance and variety can not meet the requirements of variety quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

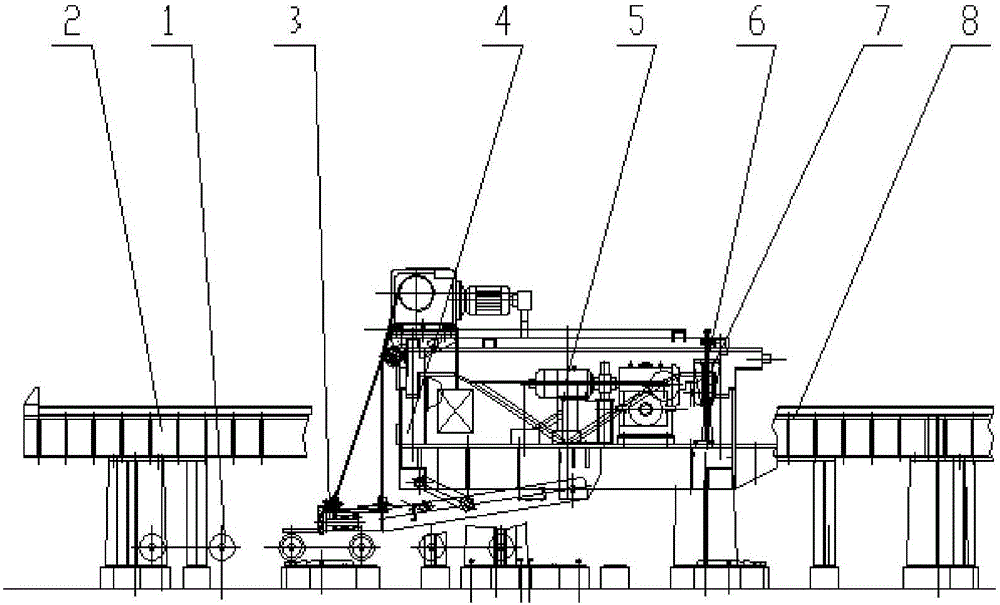

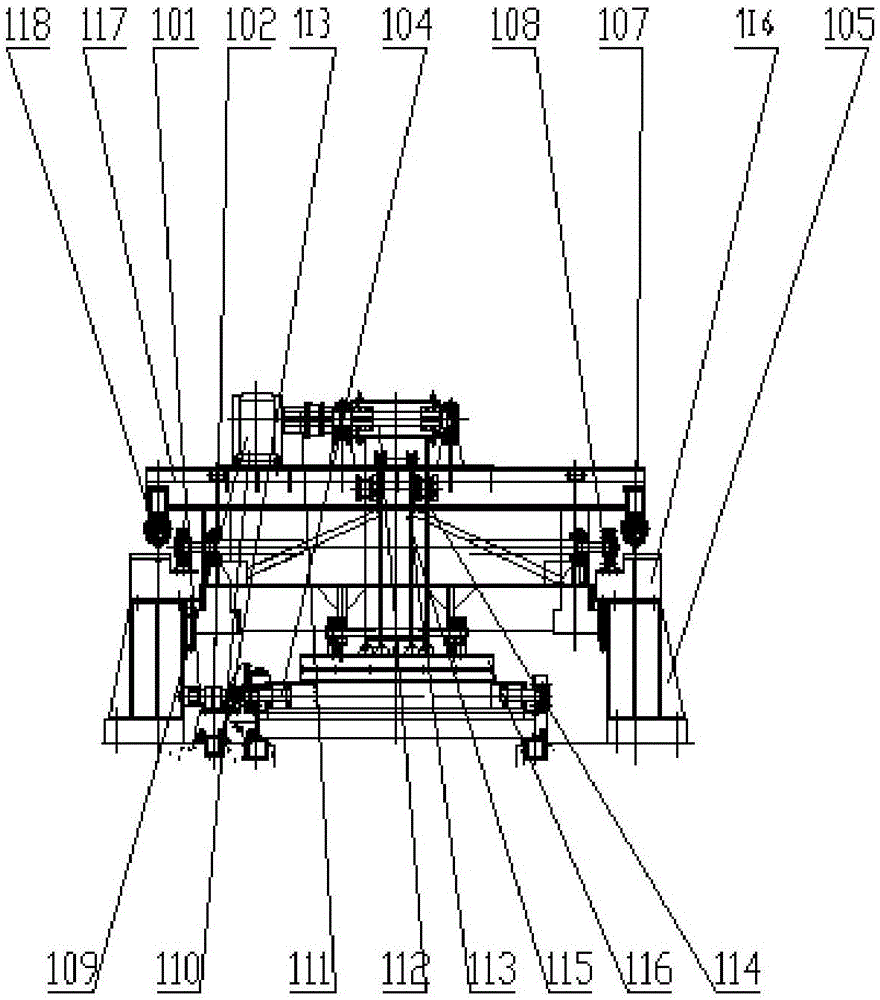

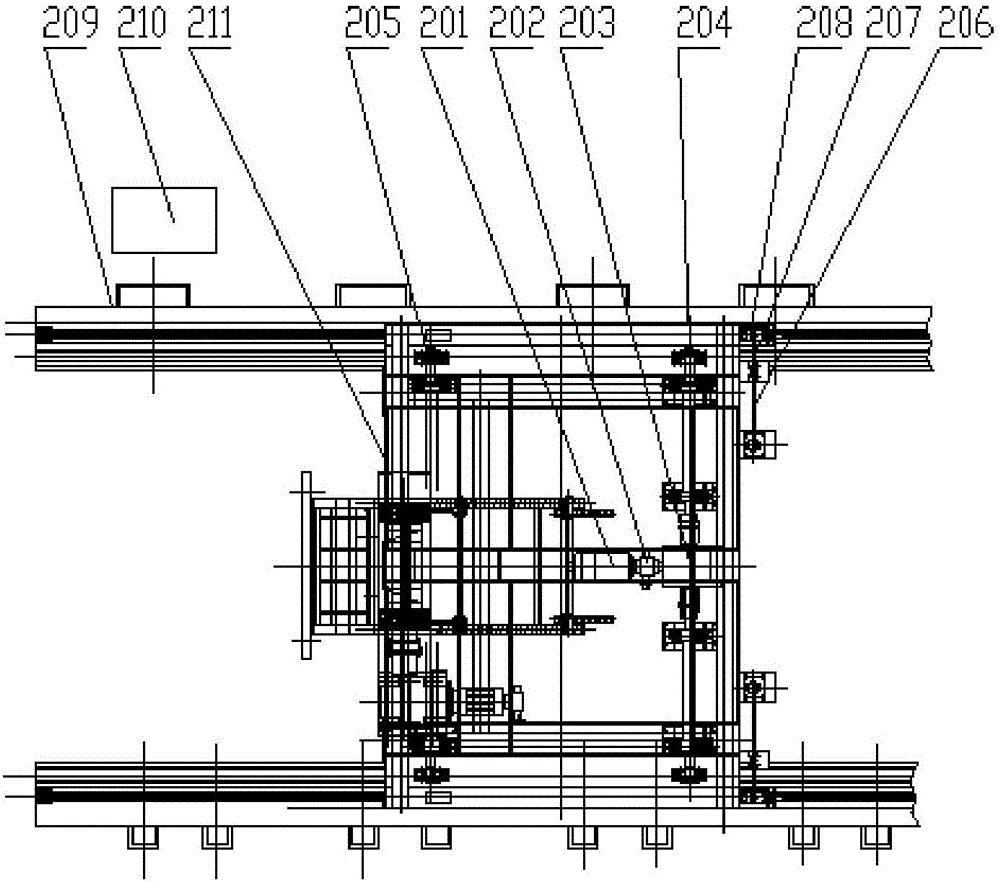

[0084] The invention provides a kind of equipment and method for mechanically sizing steel wire ropes for lifting rods and medium and thick plates, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the equipment includes a sizing roller table 1, a track device 2, a baffle lifting device 3, a sizing trolley 4, a traveling mechanism 5, a force limiting device 6, a clamping rail brake 7 and a detection control device 8, wherein the sizing The roller table 1 includes a motor one 101, a reducer 102, a shaft coupling 103 and a roller 104. The track device 2 includes a steel structure column 105, a steel structure track beam 106, a steel rail 107, and an open rack 108. The baffle lifting device 3 includes Motor two 109, reducer two 110, couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com