An equipment and control method for shearing length of aluminum alloy medium-thick plate

A control method and aluminum alloy technology, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems of high purchase cost and maintenance cost, poor measurement accuracy, etc., and achieve stable measurement, low investment cost and maintenance cost , the effect of high sizing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides an aluminum alloy medium-thick plate shearing length sizing device and a control method.

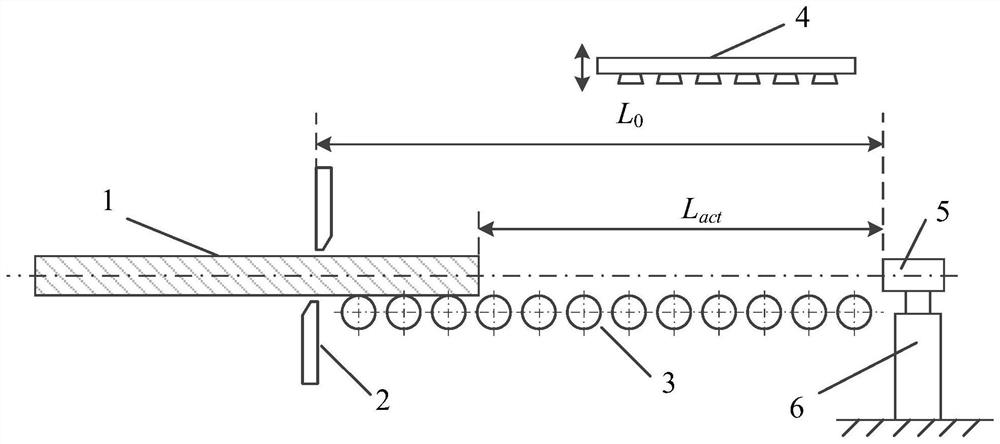

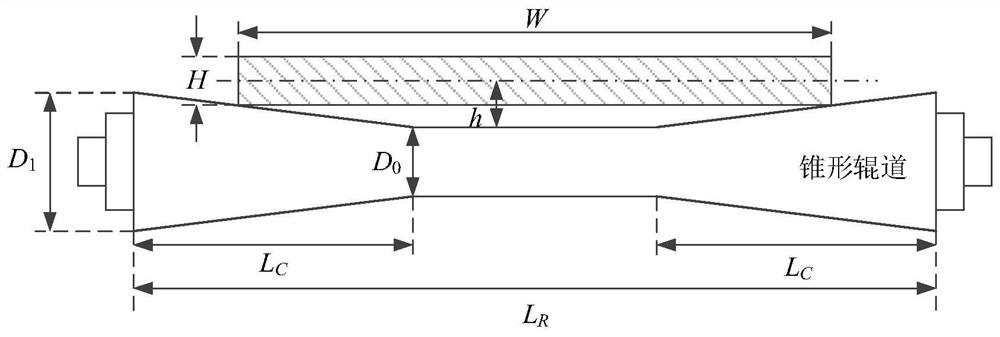

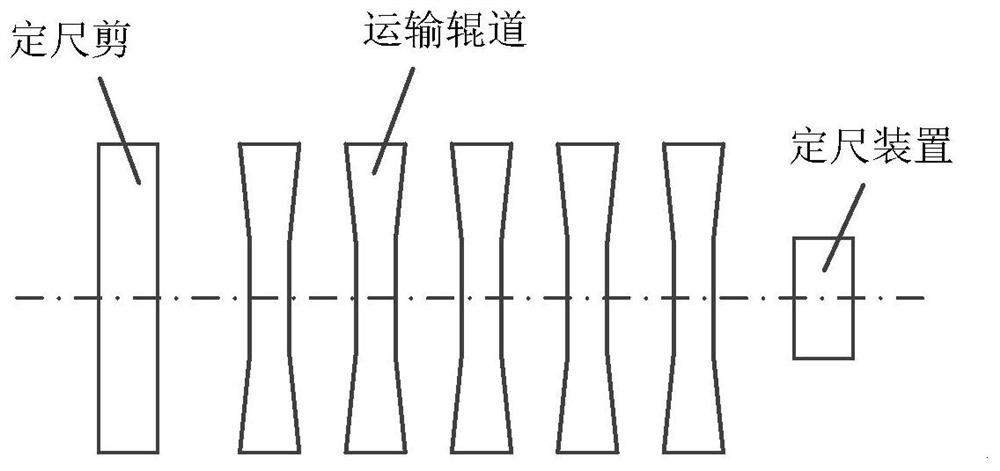

[0031] Such as figure 1 with image 3 As shown, the sizing equipment is installed at the extreme end position of the biconical conveying roller table 3, behind the aluminum plate unloading device 4, and the installation position of the sizing equipment is in the middle of the width direction of the biconical conveying roller table 3, so that The center line of the sizing equipment and the center line of the sizing scissors 2 coincide; the sizing equipment includes a hydraulic lifting device 6 and a laser rangefinder 5, the laser rangefinder 5 is installed on the lifting platform at the top of the hydraulic lifting device 6, and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com