Composite shape correction method for tooth contour of cycloidal gear of RV reducer

A technology of cycloidal wheel and reducer, which is applied in the direction of gear teeth, components with teeth, belts/chains/gears, etc. It can solve the problems of conjugated tooth profile, large force at the meshing point, and small number of tooth pairs. Achieve the effects of compensating installation errors, reducing stress concentration, improving bearing capacity and transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] This embodiment implements compound modification to the RV-40E type reducer cycloidal wheel used by the robot. The specific steps are as follows:

[0035] Step 1. Determine the tooth profile range of the working section of the cycloidal wheel

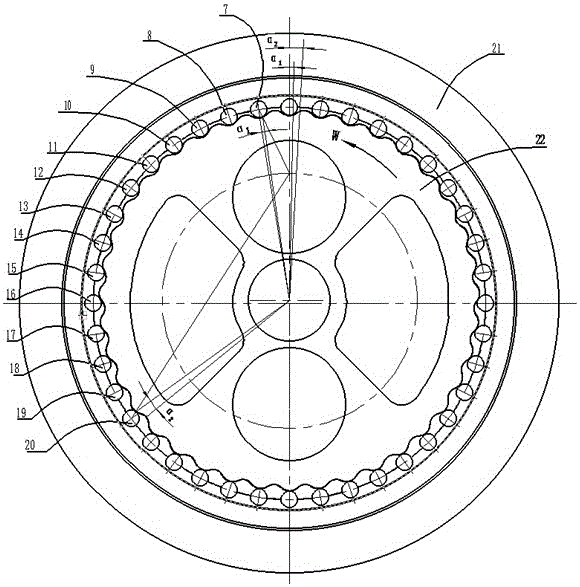

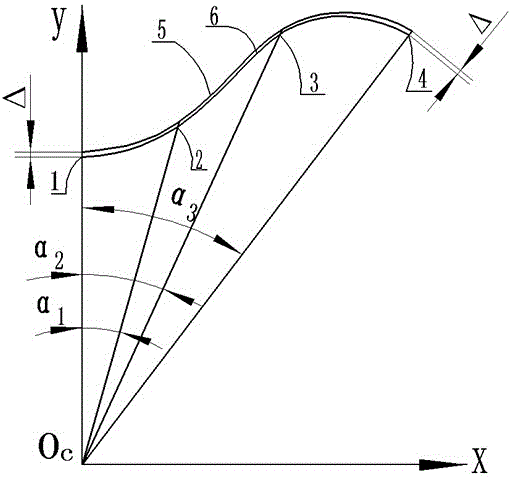

[0036] According to the requirements of transmission stability and carrying capacity, the number of teeth that the cycloidal wheel participates in meshing at the same time is initially determined when the RV reducer is working. Such as figure 1 As shown, the RV-40E reducer includes a pin gear housing 21, a standard cycloid wheel 22, and 40 pin teeth. The initial pin tooth number 7 and the final pin tooth number 20 of the cycloid wheel participate in the meshing, and the corresponding meshing Phase angle α 1 =0.0112, α 2 = 0.0591 is the position of the two boundary points of the working part of the cycloid gear profile, and the meshing phase angle range of the gear profile of the cycloid gear working section is [α 1 , α 2 ]. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com