Reciprocating wire-electric discharge machining tool

A technology for wire EDM and cutting machine tools, which is applied to electric processing equipment, metal processing equipment, accessories, etc., and can solve the problems of time-consuming and labor-intensive, limited electrode wire inclination angle, insufficient supply of working fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

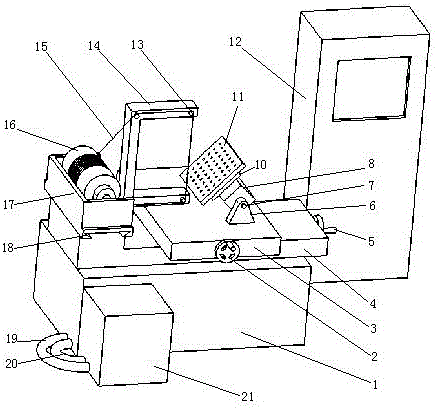

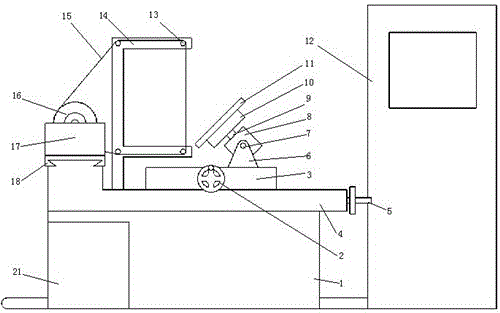

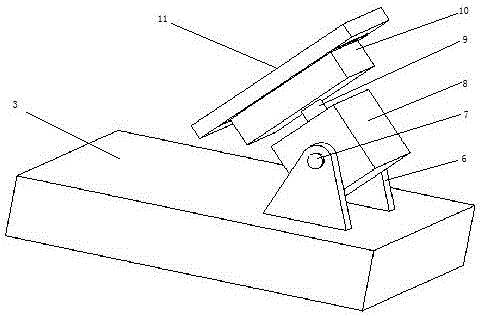

[0015] A reciprocating wire electric discharge machine tool of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see Figure 1-Figure 3 , the present invention includes a working fluid tank 21, a bed 1, a lower slide 4, an upper slide 3, a support frame 6, an overturning table 8, a rotary table 10, a workbench 11, a wire feeding device, a power supply, and a control cabinet 12. The working fluid tank 21 is connected to the bed 1 through the liquid inlet pipe 19 and the liquid outlet pipe 20. The upper end of the bed 1 is provided with a lower slide 4, and the upper end of the lower slide 4 is provided with an upper slide 3. The upper end of the upper slide plate 3 is provided with an overturning table 8, a rotating table 10 and a working table 11 in sequence. The wire transporting device includes a wire feeding slide 18, a protective cover 17, a wire storage cylinder 16, a guide wheel 13, an electrode wire 15 and a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com