Equal-wall thickness curve generatrix part precise molding method

A curved generatrix and equal wall thickness technology, applied in the field of precise plastic processing, can solve the problems of less reinforcement of parts, low product strength, and many processes, and achieve the effects of high production efficiency, high product strength and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

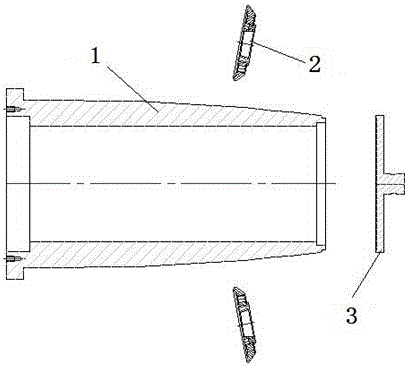

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] This example takes the manufacturing method of a curved busbar part with equal wall thickness as an example, and elaborates in detail the core technical issues of obtaining this type of part by using strong generalized spinning technology:

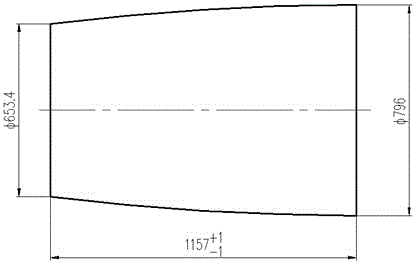

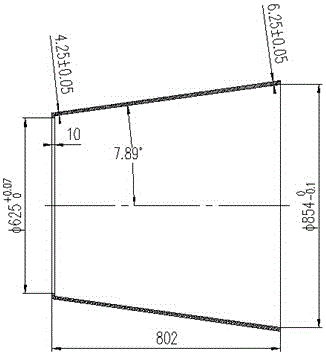

[0027] The material of the target product in this embodiment is 5A06, and the structure size is as follows figure 1 Shown, where the wall thickness requirement δ=3±0.1mm, the strength requirement σ s ≥309Mpa, σ b ≥417MPa. Generally speaking, the product precision requirements are high, and the product strength is much higher than the index of the base metal tensile strength of 315Mpa;

[0028] The processing scheme determined in this embodiment is "machining (forging billet)-spinning-machining (finished product)". Among them, the supply status of purchased forging blanks is 5A06-O, and the raw material standards are implement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com