Laser combined-machining grinding machine

A composite processing and laser processing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of limited movement direction, only up and down movement, errors, etc., to achieve the depth of easy quenching, control the depth of quenching, processing good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

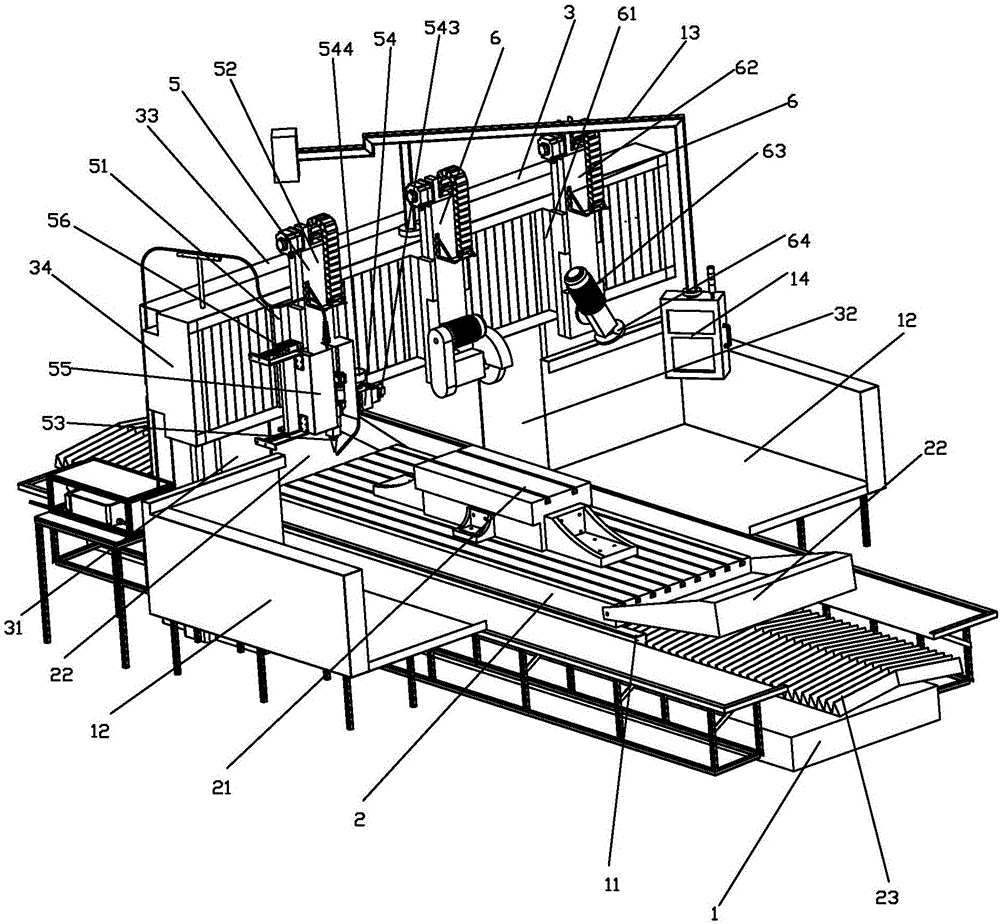

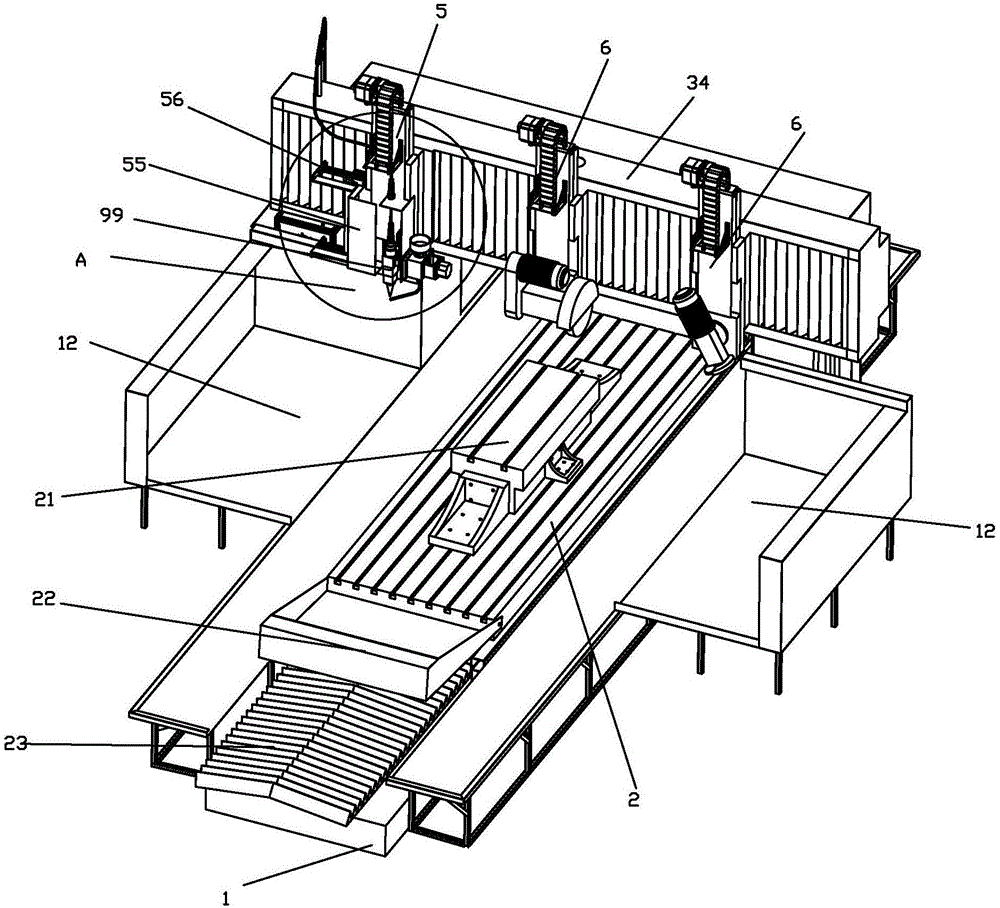

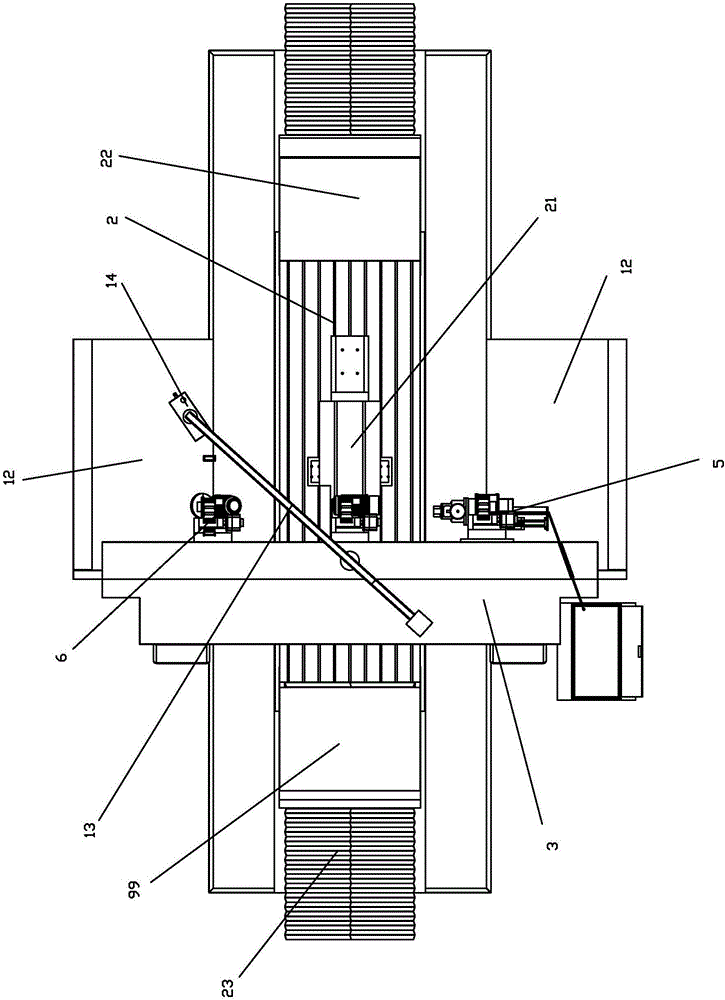

[0030] A kind of laser compound processing grinding machine, it comprises base 1, and base 1 is provided with workbench 2, and base 1 is provided with workbench frame 11, and workbench 2 can slide back and forth and is arranged on workbench frame 11, and workbench is also provided with Fixture 21. A support 3 is provided above the base 1, and the support 3 is provided with a laser processing mechanism 5 and a grinding wheel mechanism 6 that can move laterally on the support and process workpieces on the workbench. The grinding machine of the present invention can use the laser processing mechanism 5 to complete the processes of laser welding, laser quenching, laser cladding of large guide rails, and use the grinding wheel mechanism 6 to grind the guide rail surface at the same time in one clamping, reducing errors caused by repeated clamping.

[0031] The left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com