Dynamic and intelligent continuous operation control method and production line for aluminum welded pipes

A technology of intelligent control and control method, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of low degree of intelligence, inability to effectively ensure the quality stability of high-frequency welding of aluminum alloy ultra-thin-walled pipes, and on-site operators The level of proficiency depends on high-level problems to achieve the effect of increasing the degree of intelligence, shortening the debugging time and cost, and improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] An embodiment, the aluminum welded pipe dynamic intelligent control continuous operation control method provided in this embodiment includes the following steps:

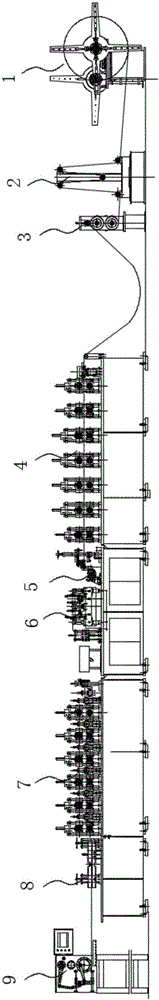

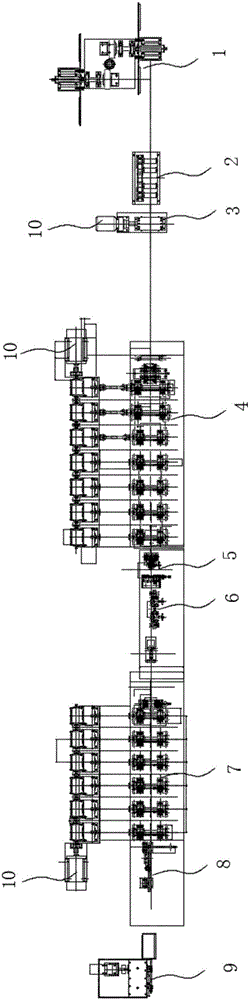

[0043] (1) On the same aluminum welded pipe production line, double-cone head uncoiling device 1, aluminum strip tension device 2, pinch roller device 3, forming device 4, extrusion device 5, external burr removal device 6, flat forming device 7, Calibration device 8 and flying shearing device 9;

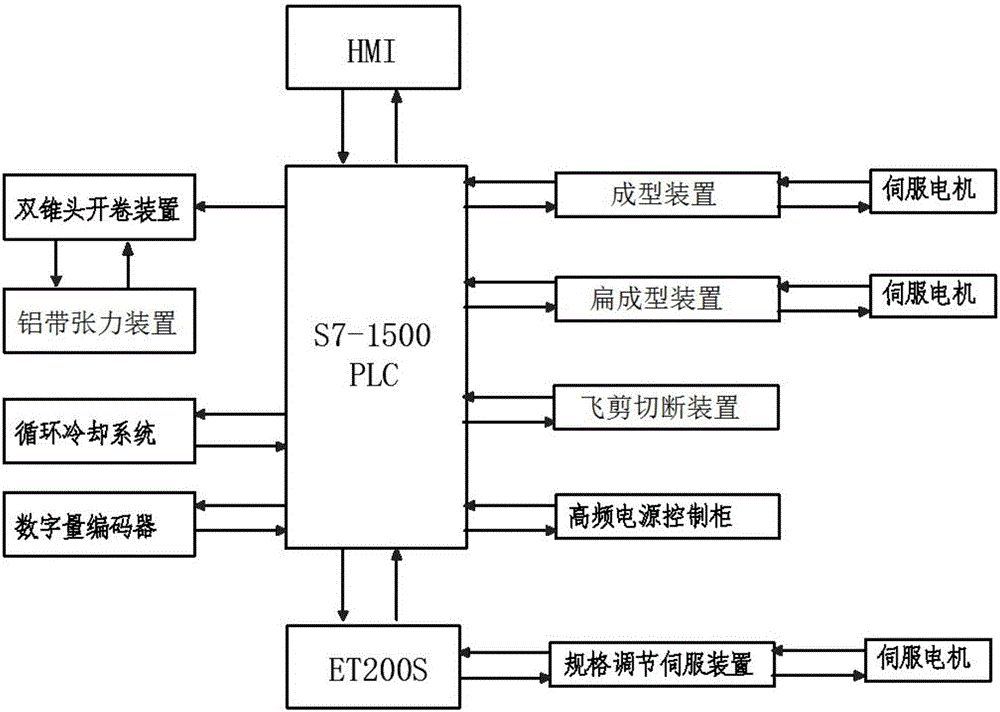

[0044] (2) Set up a dynamic intelligent control device, which includes a control unit, and a closed-loop control system for unwinding with material connected to the control unit, a closed-loop control system for pinch rollers, and a closed-loop control system for specification adjustment;

[0045]The strip unwinding closed-loop control system includes a tension sensor arranged in the aluminum strip tension device 2, the pinch roller closed-loop control system includes a photoelectric detection sensor arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com