Pan shaking method driven by rotary torque

A technology of rotating torque and turning the pot, which is applied in the field of turning the pot driven by the rotating torque, can solve the problems of multiple moving parts, large overall structure, inconvenient cleaning of the bottom of the pot, etc. Smooth, cooking-enhancing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

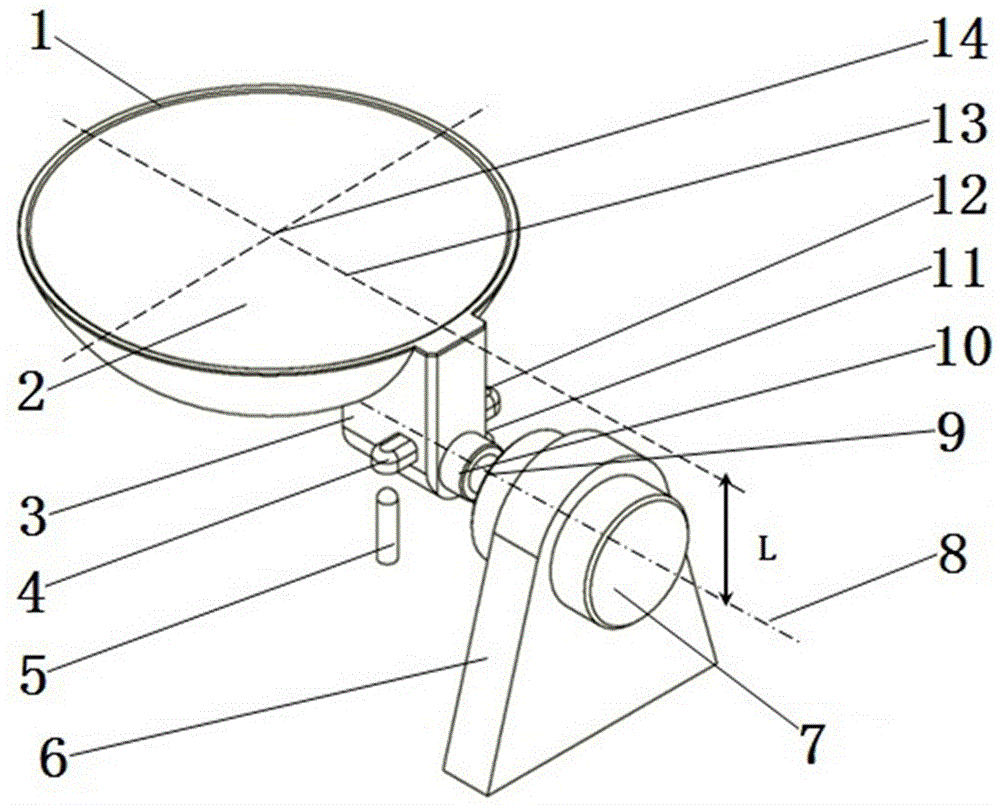

[0024] Embodiment 1: In this embodiment, the method of turning the pot driven by rotational torque is set on the pot body such as figure 1 Shown in the pan mechanism to achieve. Such as figure 1 As shown, the pot tilting mechanism is arranged on the pot body 1 , and the bottom surface 2 of the pot body is used to hold ingredients, and the ingredients are cooked in the pot body 1 .

[0025] A pot body support 3 is fixedly arranged on one side of the pot body 1, and a connecting structure can be used between the pot body support 3 and the pot body 1 to connect and fix the two or directly form the pot body 1 and the pot body support 3 into one body structure. One side surface of the pot body support 3 is set to an arcuate surface matched with the shape of the outer surface of the pot body 1, and the side surface corresponding to the arcuate surface is set to a plane; The outer surfaces of the pot body 1 are fitted together and connected and fixed, and a pot turning shaft 10 is...

Embodiment 2

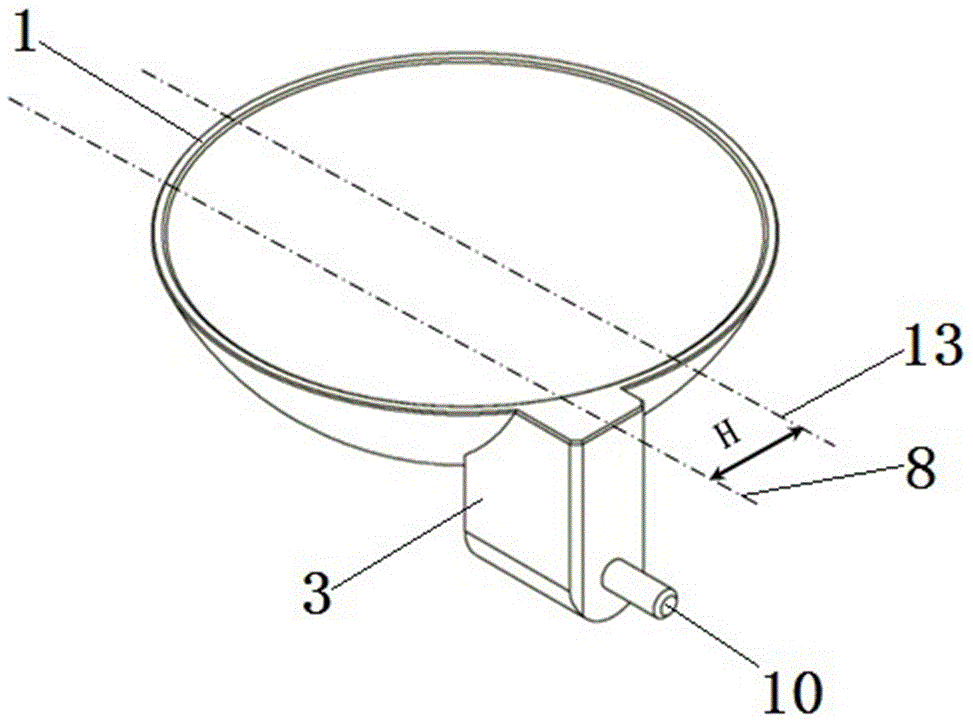

[0034] Embodiment 2: Compared with Embodiment 1, this embodiment is different in that: the installation position of the rotating shaft 10 for inverting the pot is different, thus affecting the effect of inverting the pot. Such as figure 2 As shown, there is a distance H between the center line 8 of the pot rotation axis 8 of the pot rotation shaft 10 and the bisector 13 of the pot body in the horizontal direction, and H in Embodiment 1 is equal to zero, that is, the pot in this embodiment The rotating shaft 10 is arranged at a side position deviated from the bisector 13 of the upper plane of the pot body. In this way, different pot-stirring effects can be obtained and the pot-stirring needs of various ingredients can be met.

Embodiment 3

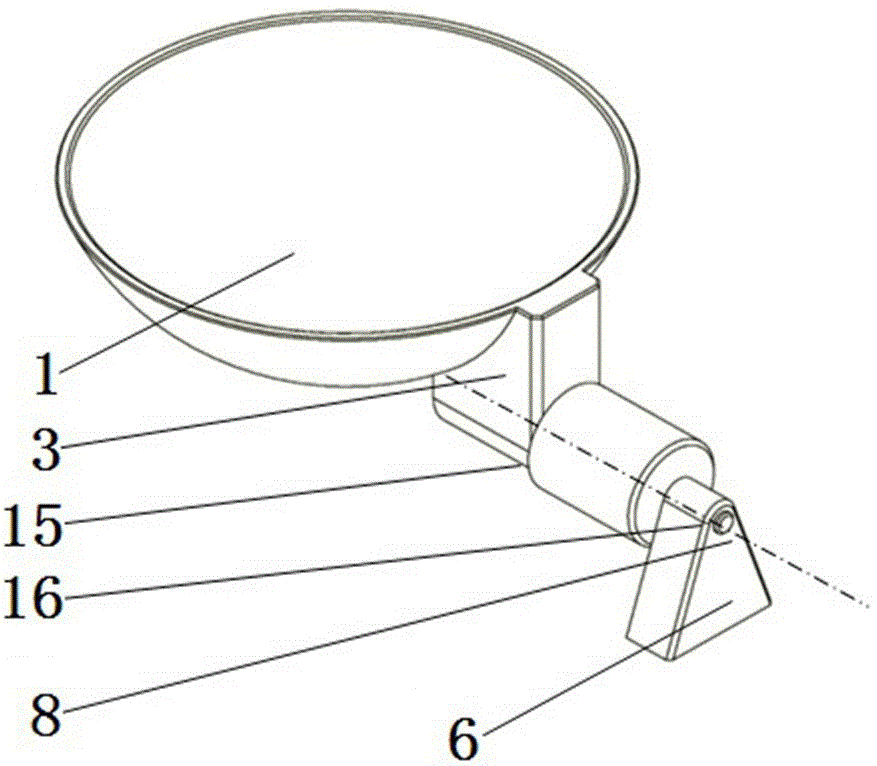

[0035] Embodiment 3: Compared with Embodiments 1 and 2, this embodiment differs in that: the composition and structure of the pot-turning mechanism are different. Such as image 3 As shown, the motor outer rotor 15 is directly connected to the pot body support 3, the outer rotor motor shaft 16 is installed on the support 6, and the outer rotor motor shaft 16 drives the motor outer rotor 15 to rotate, thereby driving the pot body 1 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com