Solid tire carrying manipulator and tire transfer device with same

A transfer device and manipulator technology, applied in manipulators, program-controlled manipulators, transportation and packaging, etc., can solve the problems of difficulty in meeting the production rhythm of molding machines, waste of production capacity, time-consuming and labor-intensive problems, and achieve compact structure, improved efficiency, and space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

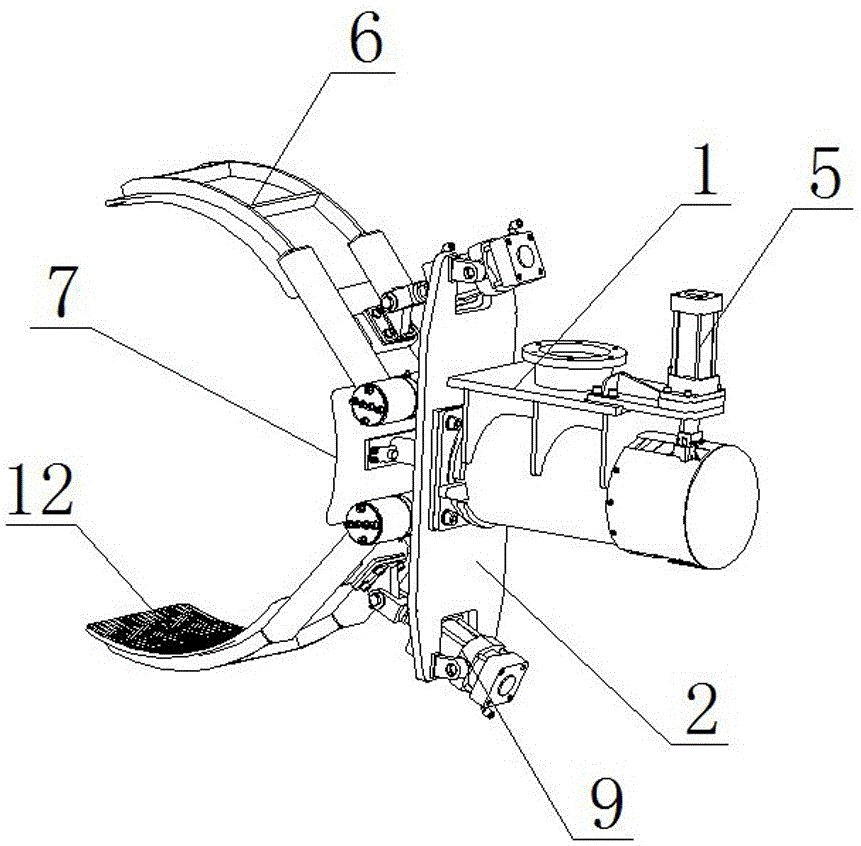

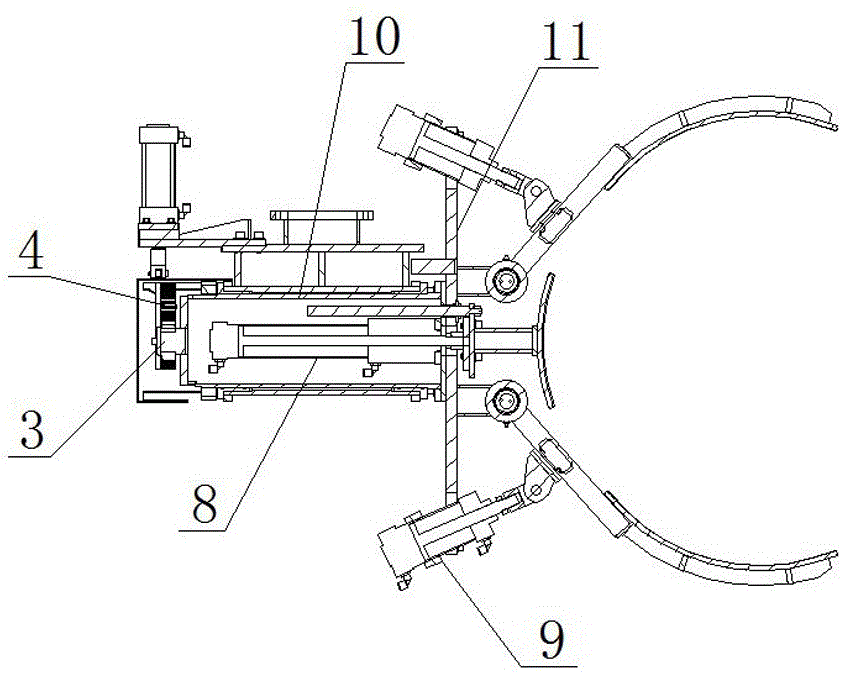

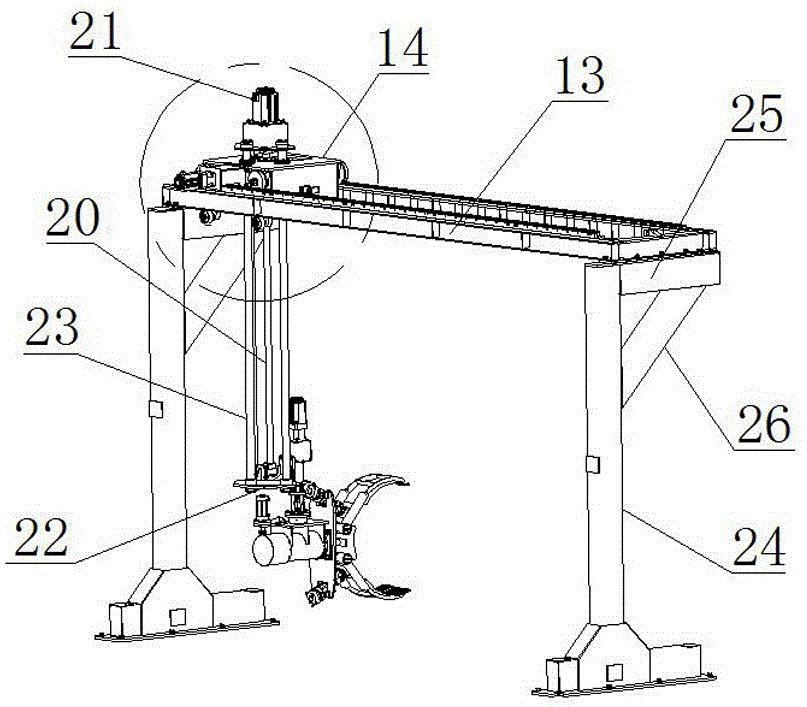

[0021] As shown in the figure, a solid tire handling manipulator of the present invention includes a fixed frame 1, a rotating frame 2, a gear 3, a rack 4, a vertical drive cylinder 5, two jaws 6, a push jaw 7, a locking Cylinder 8 and two clamping cylinders 9, the rotating frame 2 includes a roller 10 and a jaw bracket 11, the roller 10 is fixed on one side of the jaw bracket 11, the roller 10 is rotated and installed in the fixed frame 1, and the gear 3 is fixed on one end of the roller 10 The rack 4 is vertically arranged on one side of the gear 3 and meshes with the gear 3. The upper end of the rack 4 is connected to the vertical drive cylinder 5 and driven by the vertical drive cylinder 5. The vertical drive cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com