A one-pot high-yield producing method for tetrahydrothiophene

A tetrahydrothiophene, high-yield technology, applied in the direction of organic chemistry, can solve the problems of difficult product separation, affecting the application of downstream products, and difficult separation of water and products, achieving high yield and purity, low cost, and environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

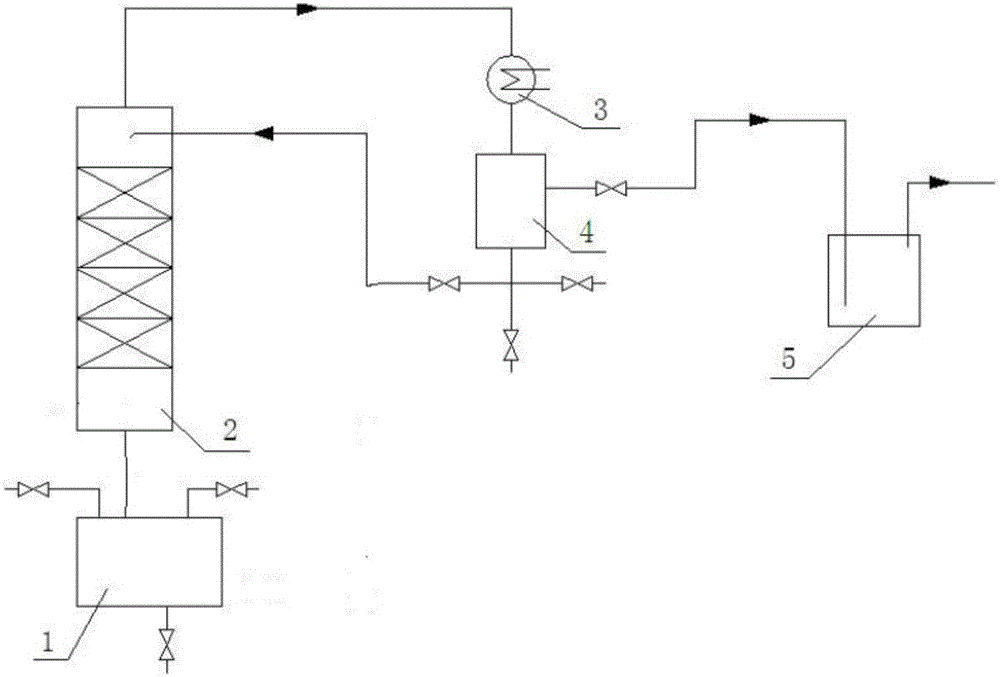

[0020] Past figure 1 Add 164Kg60% content of anhydrous sodium sulfide in the shown 1000 liters of enamel reaction kettle 1, 480Kg solvent N-methylpyrrolidone, 3.2Kg phase transfer catalyst benzyltriethylammonium chloride, stir and heat up; keep the reaction temperature at 50-100°C , Slowly add 160Kg of 1,4-dichlorobutane into the reactor 1 dropwise. After the dropwise addition is completed, the reaction time is 3 to 6 hours. Continue heating to 115-122°C, and use the enamel packed tower 2 to distill under normal pressure to obtain the refined tetrahydrothiophene. The tetrahydrothiophene fine product weighs 142.5Kg, the tetrahydrothiophene content is 99% according to gas chromatography analysis, and the yield is greater than 95%. The tail gas is cooled by the sheet-type enamel condenser 3, separated by the gas-liquid separator 4, and enters the tail gas absorption tank 5 to be absorbed by water and alkali, and then emptied.

Embodiment 2

[0021] Embodiment 2~6: with embodiment 1, only anhydrous sodium sulfide consumption is different.

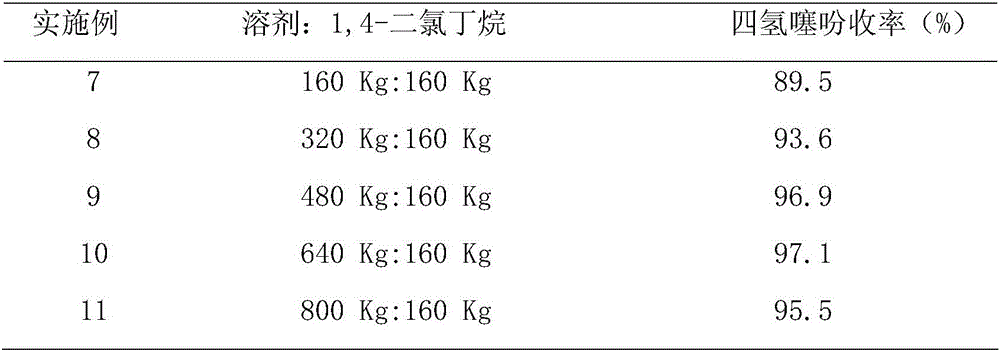

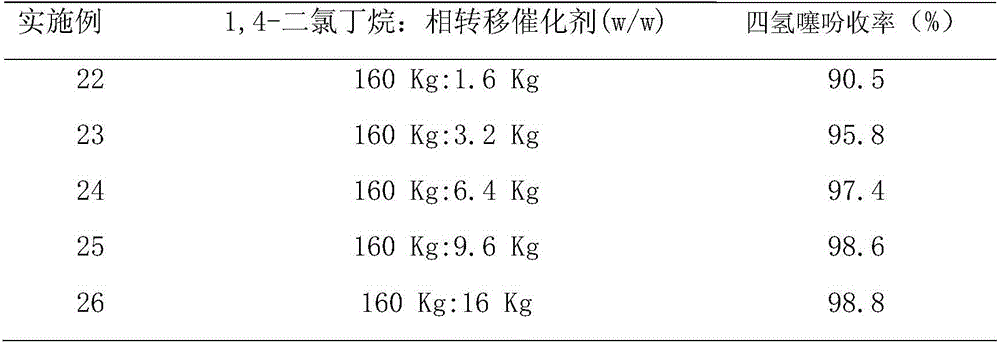

[0022] During the reaction process, keep 480Kg N-methylpyrrolidone, 160Kg 1,4-dichlorobutane, 3.2Kg phase transfer catalyst benzyltriethylammonium chloride, the reaction temperature is 50-100°C, and the reaction time is 3-6 hours , by changing the amount of anhydrous sodium sulfide, investigate the effect of the amount of anhydrous sodium sulfide on the yield of tetrahydrothiophene.

[0023] According to the content of tetrahydrothiophene detected by gas chromatography, the yield of calculated tetrahydrothiophene is shown in Table 1.

[0024] The impact of the amount of anhydrous sodium sulfide in table 1 on the yield of tetrahydrothiophene

[0025]

[0026] As can be seen from Table 1, in the case of 160Kg 1,4-dichlorobutane, changing the addition of anhydrous sodium sulfide, the addition of anhydrous sodium sulfide is 164 ~ 205Kg can meet the production needs. It shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com