Non-destructive repair waterproof paint of external wall

A waterproof coating and exterior wall technology, which is applied in the direction of coating, etc., can solve the problems of coating film pollution, coating film difficult to rinse with rainwater, and affecting the overall appearance of buildings, etc., to achieve simple preparation and use process, good weather resistance and water resistance , Conducive to the effect of marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment prepares the above-mentioned coating according to the following proportion and process, in terms of weight fraction: put 67% of water-based acrylic resin and 6.6% of silane nanometer into the dispersion tank and stir for 25min, then add 24% of reinforcing powder and 0.8% of defoamer, and stir After 15 minutes, add 0.8% fungicide and stir evenly. Finally, add 0.8% thickener until the mixture is evenly stirred. Then check the viscosity. If the viscosity value is 90-100KU, it is up to the standard. Otherwise, continue stirring until the viscosity reaches the standard, and finally inject The coating can be obtained by filtering in a filter container.

Embodiment 2

[0024] This embodiment prepares the above-mentioned coating according to the following proportions and processes, in terms of weight fraction: put 61% of water-based acrylic resin and 7.1% of silane nanometer into the dispersion tank and stir for 30min, then add 29% of reinforcing powder and 1% of defoamer, and stir After 20 minutes, add 1% fungicide and stir evenly. Finally, add 0.9% thickener until the mixture is evenly stirred. Then check the viscosity. If the viscosity value is 90-100KU, it is up to the standard. Otherwise, continue stirring until the viscosity reaches the standard. Then inject and filter The container is filtered to obtain the coating.

Embodiment 3

[0026] The present embodiment prepares the above-mentioned coating according to the following proportions and processes, in terms of weight fraction: put 68% of water-based acrylic resin and 7.8% of silane nanometer into the dispersion tank and stir for 40 minutes, then add 22% of reinforcing powder and 0.5% of defoamer, and stir After 30 minutes, add 0.8% fungicide and stir evenly. Finally, add 0.9% thickener until the mixture is evenly stirred. Then check the viscosity. If the viscosity is 90-100KU, it is up to standard. Otherwise, continue stirring until the viscosity reaches the standard, and then inject and filter. The container is filtered to obtain the coating.

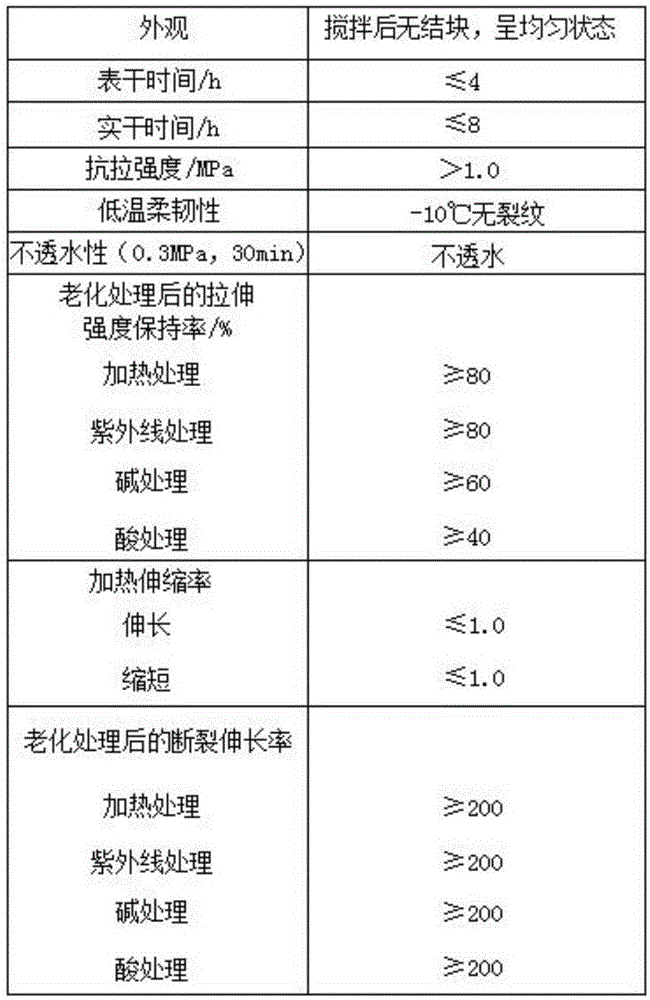

[0027] The coatings obtained in the above three examples have excellent waterproof performance and good wall adhesion. In particular, the coatings are mixed with water-based acrylic resin and reinforcing powder without adding cement, so that the coatings are transparent after being coated on the walls. Moreover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com