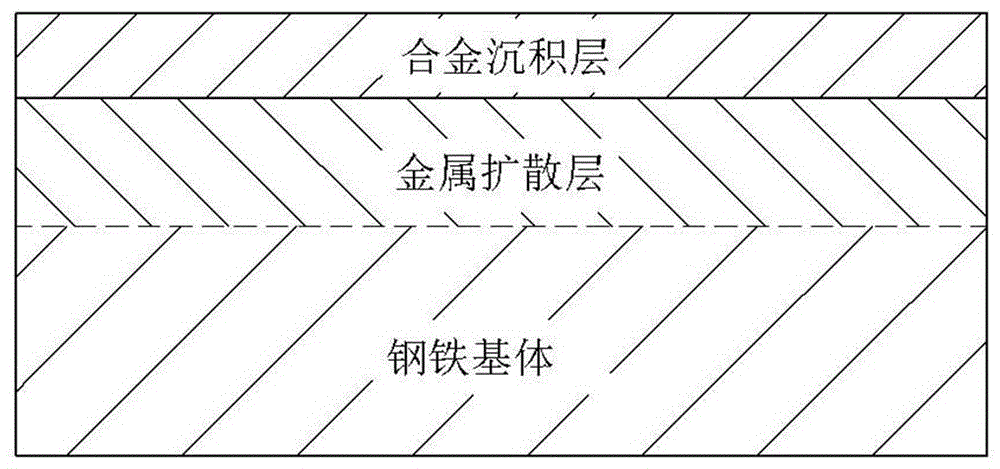

Steel surface modification structure formed through zinc-nickel infiltrated layer and preparation method for steel surface modification structure

A steel surface modification technology, which is applied in the field of steel modification structure, can solve the problems that the anti-corrosion requirements cannot be met, the corrosion resistance of the anti-corrosion layer cannot meet the anti-corrosion requirements, and the hardness is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

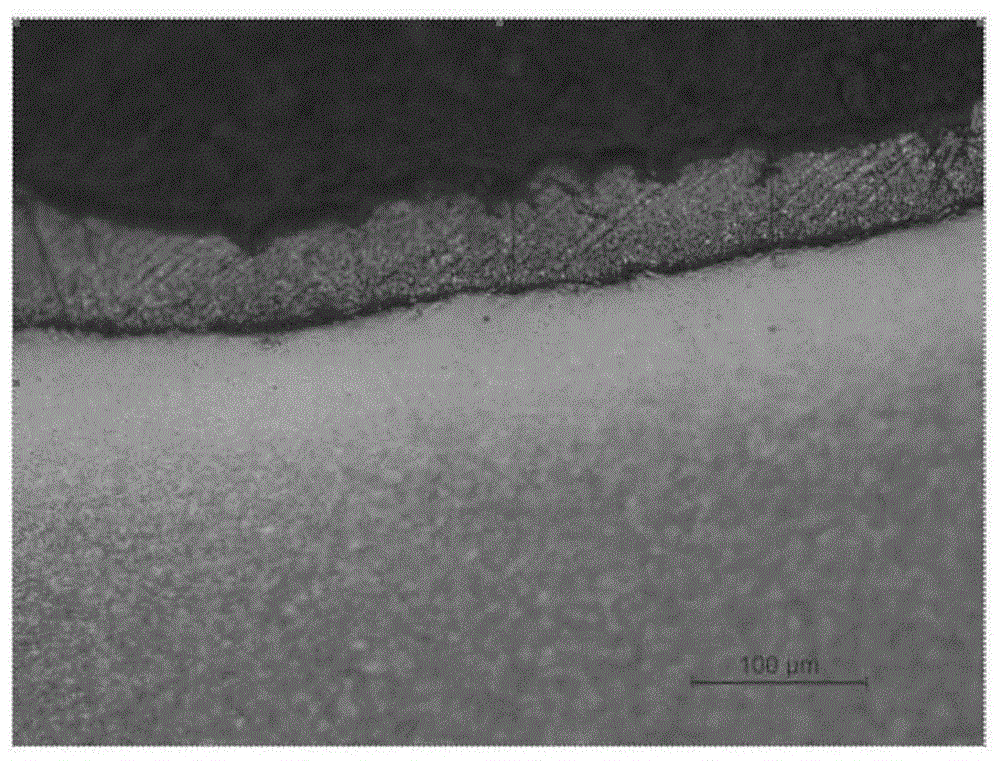

[0048] see figure 2 , is a metallographic cross-sectional view of the non-quenched-tempered 45 steel provided by the present invention after surface modification treatment. In this embodiment, the steel matrix is 45 steel in medium carbon steel, and the surface modification process of the non-quenched-tempered 45 steel is as follows:

[0049] In this embodiment, the steel matrix is medium carbon steel, specifically, the medium carbon steel is 45 steel, and the surface modification process is as follows:

[0050] Firstly, pretreatment is carried out on the surface of the steel substrate, which specifically includes carrying out alkali washing, degreasing and shot blasting derusting on the steel substrate. The specific steps of alkali washing degreasing and shot blasting rust removal have been described above, and will not be repeated here.

[0051] Then configure the penetrating modifier. In this embodiment, the penetrating modifier is in the form of powder as a whole, a...

Embodiment 2

[0057] Please also see Figure 3-Figure 7 ,in image 3 It is the metallographic cross-sectional view of the quenched-tempered 45 steel provided by the present invention after surface modification treatment; Figure 4 It is the metallographic cross-sectional view of the quenched-tempered 42CrMoA steel provided by the present invention after surface modification treatment; Figure 5 It is the metallographic cross-sectional view of the quenched-tempered 35CrMo steel provided by the present invention after surface modification treatment; Image 6 It is the metallographic cross-sectional view of the quenched-tempered 35VB steel provided by the present invention after surface modification treatment; Figure 7 It is a metallographic cross-sectional view of the quenched-tempered 40Cr steel provided by the present invention after surface modification treatment.

[0058] In this embodiment, the steel base is medium carbon steel or medium carbon alloy steel. Specifically include 45 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com