Preparation method of carbonized wood loaded PdCo alloy composite electrocatalyst

An electrocatalyst and carbonized wood technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of limited usability and sustainability, increase the electrochemical active area, facilitate penetration and diffusion, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of carbonized wood supported PdCo alloy composite electrocatalyst of the present invention, concrete method is as follows:

[0034] (1) Cut basswood horizontally into wood chips with a length and width of 2×0.5cm and a thickness of 0.1cm, wash the wood chips, and then soak the wood chips in 0.3mol / L zinc chloride solution at 30°C for 24 hours, take them out Dry in an oven at 80°C for 12 hours;

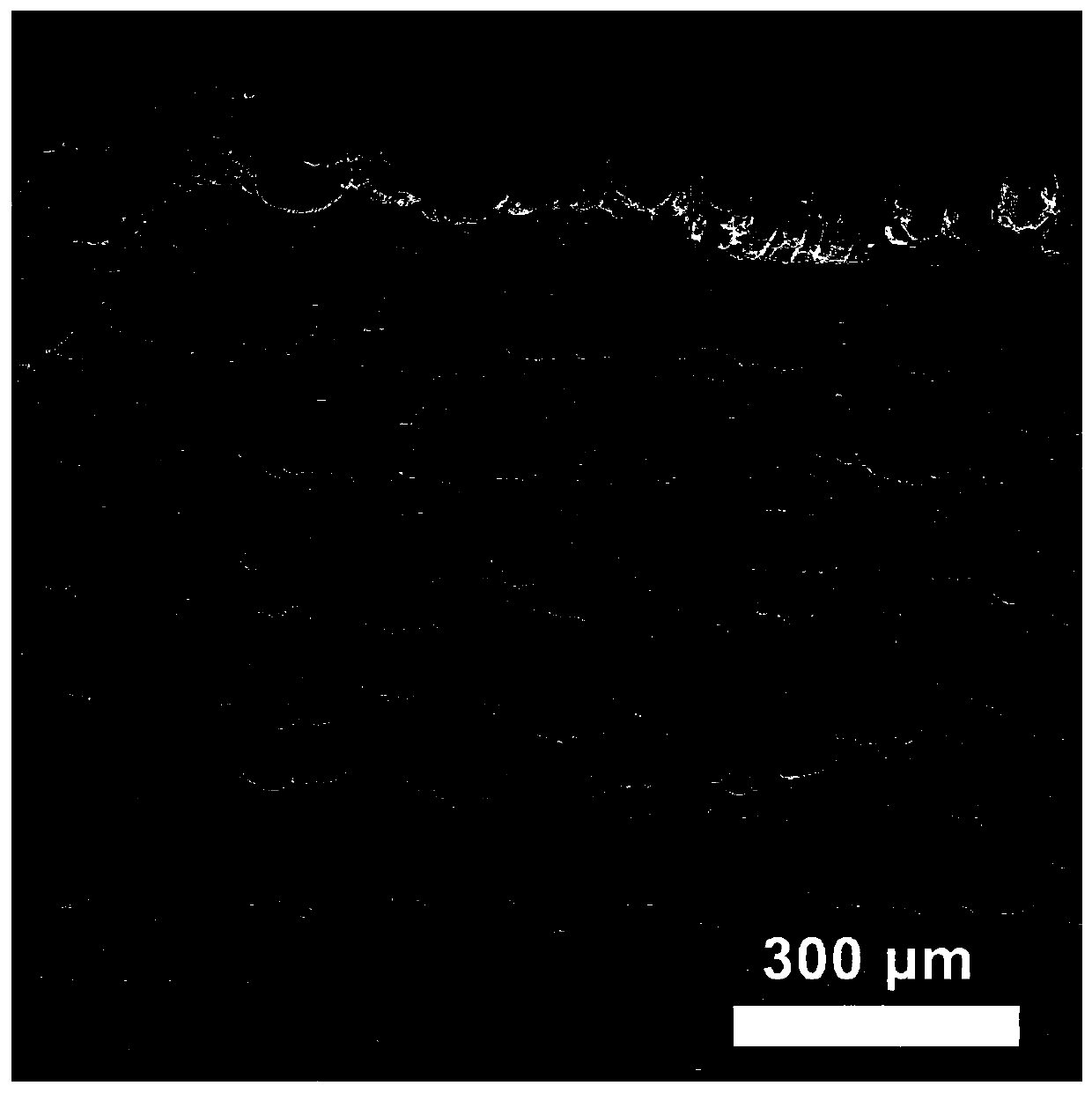

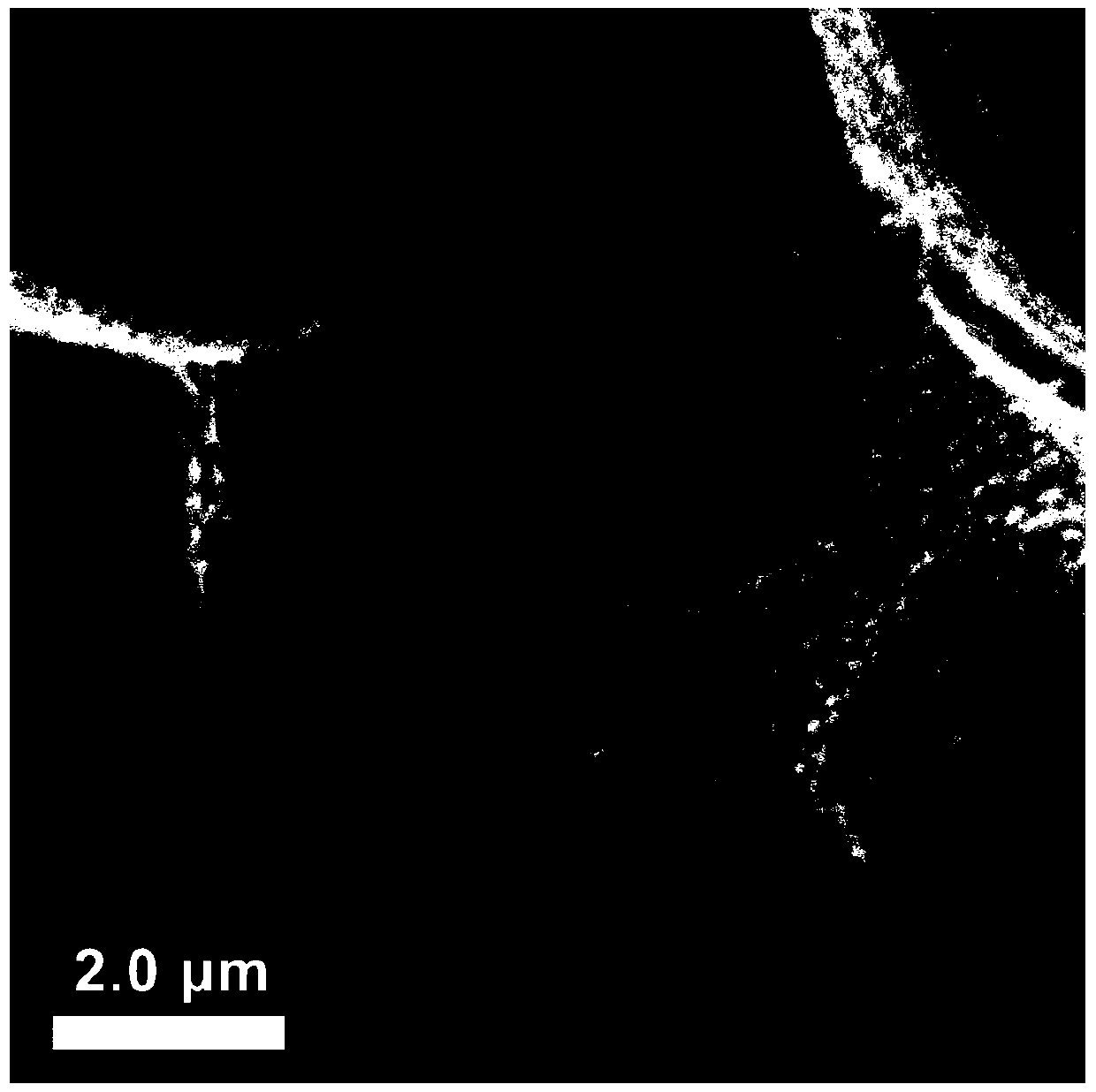

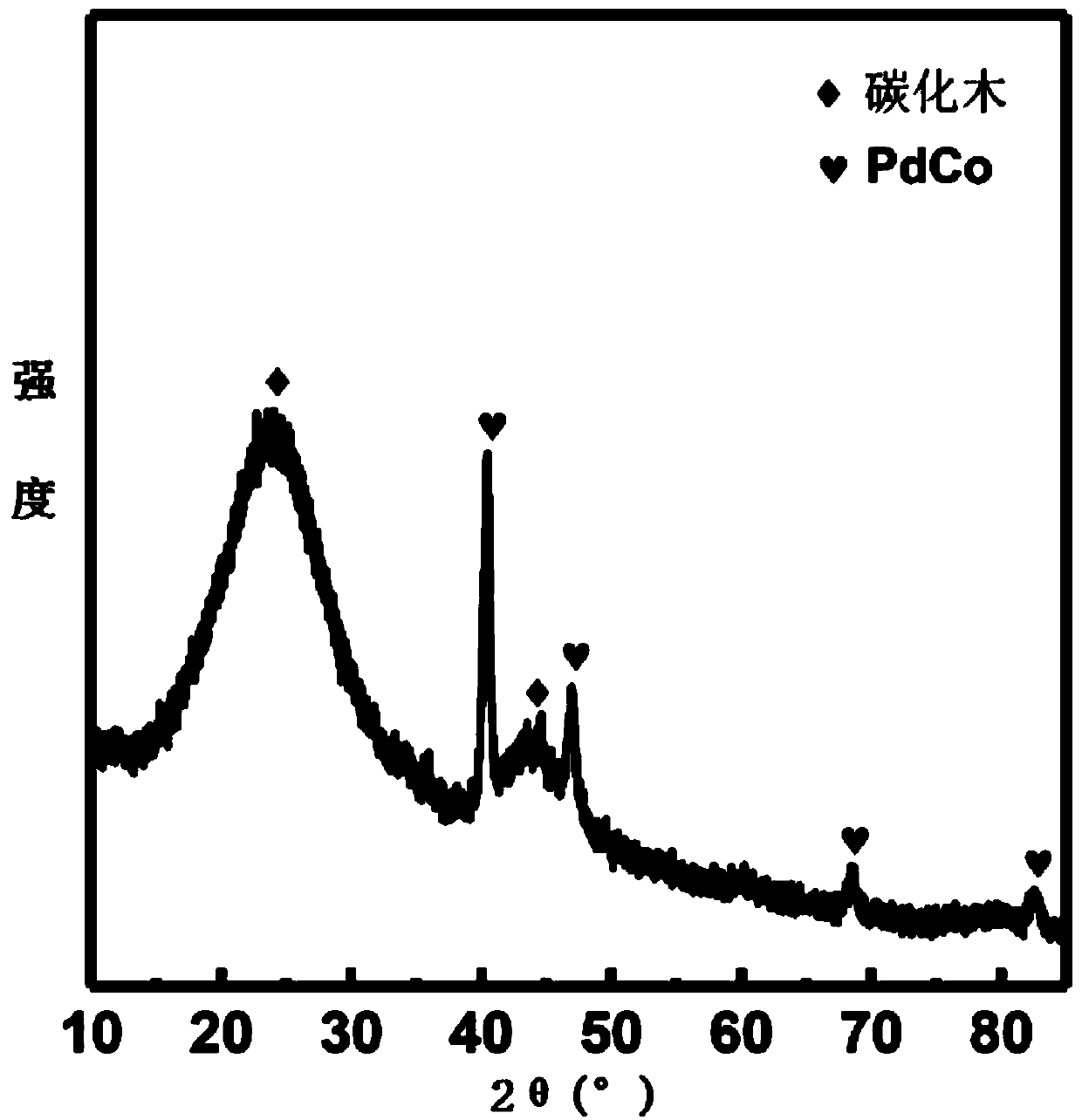

[0035] (2) Put the dried wood chips in a tube furnace, under the protection of nitrogen atmosphere, first raise the temperature to 500°C at a heating rate of 5°C / min, keep it warm for 1h, and then raise the temperature at a heating rate of 5°C / min To 900°C, keep warm for 3 hours, and finally cool naturally to room temperature under the protection of nitrogen to obtain three-dimensional porous carbonized wood derived from wood;

[0036] (3) With the carbonized wood prepared in step (2) as the working electrode, a spectrally pure graphite rod with a diamete...

Embodiment 2

[0043] The preparation method of carbonized wood supported PdCo alloy composite electrocatalyst of the present invention, concrete method is as follows:

[0044] (1) Cut basswood horizontally into wood chips with a length and width of 2.5×1.0cm and a thickness of 0.2cm, wash the wood chips, and then soak the wood chips in 0.2mol / L zinc chloride solution at 25°C for 24 hours, take them out Dry in an oven at 60°C for 24 hours;

[0045] (2) Put the dried wood chips in a tube furnace, under the protection of nitrogen atmosphere, first raise the temperature to 400°C at a heating rate of 3°C / min, keep it warm for 1.5h, and then heat it at a heating rate of 3°C / min Raise the temperature to 800°C, keep it warm for 4 hours, and finally cool it down to room temperature naturally under the protection of nitrogen to obtain a three-dimensional porous carbonized wood derived from wood;

[0046] (3) With the carbonized wood prepared in step (2) as the working electrode, a spectrally pure gr...

Embodiment 3

[0049] The preparation method of carbonized wood supported PdCo alloy composite electrocatalyst of the present invention, concrete method is as follows:

[0050] (1) Cut basswood horizontally into wood chips with a length and width of 2.0×1.0cm and a thickness of 0.3cm, wash the wood chips, and then soak the wood chips in 0.4mol / L zinc chloride solution at 30°C for 12 hours, take them out Dry in an oven at 70°C for 18 hours;

[0051] (2) Put the dried wood chips in a tube furnace, under the protection of nitrogen atmosphere, first raise the temperature to 300°C at a heating rate of 4°C / min, keep it warm for 2h, and then raise the temperature at a heating rate of 4°C / min to 700°C, keep warm for 5 hours, and finally cool naturally to room temperature under the protection of nitrogen to obtain three-dimensional porous carbonized wood derived from wood;

[0052] (3) With the carbonized wood prepared in step (2) as the working electrode, a spectrally pure graphite rod with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com