Full-automatic production line for right-angle bed sheet

A fully automatic, production line technology, applied in textile and paper making, sewing unit, cloth pressing mechanism, etc., can solve the problems of requiring manual participation, high price, low efficiency, etc., and achieve good processing effect, improve processing efficiency, and fabric flatness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

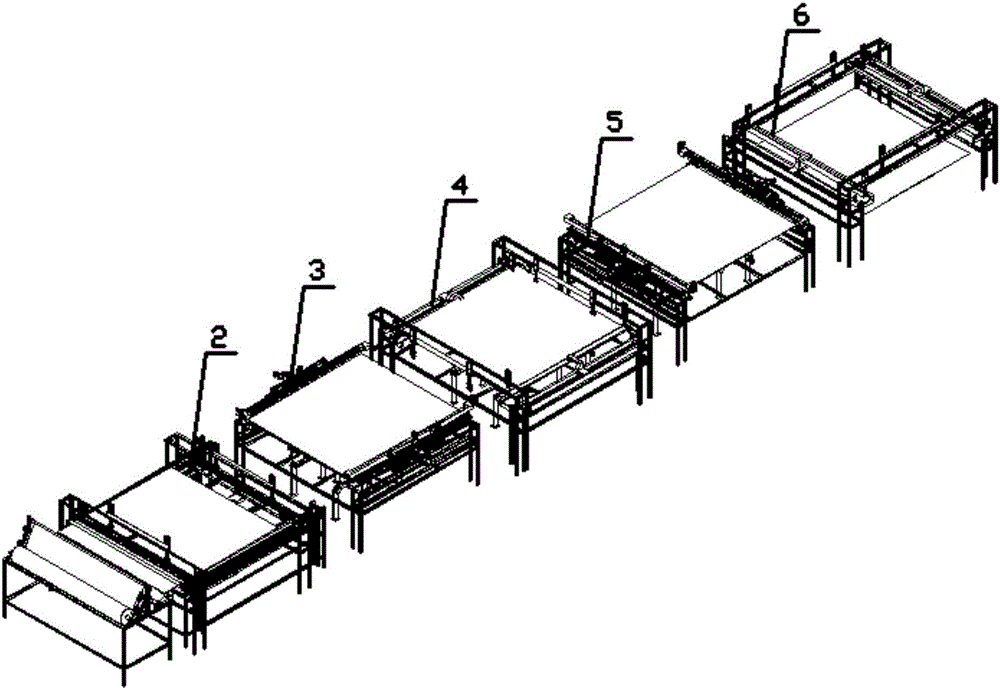

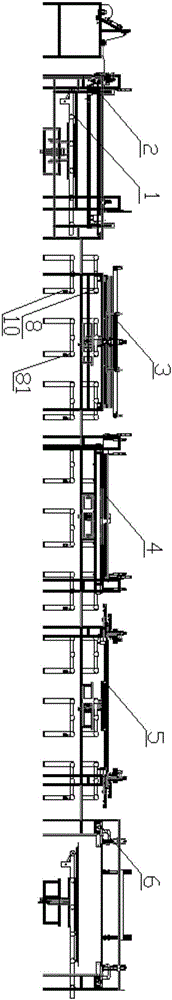

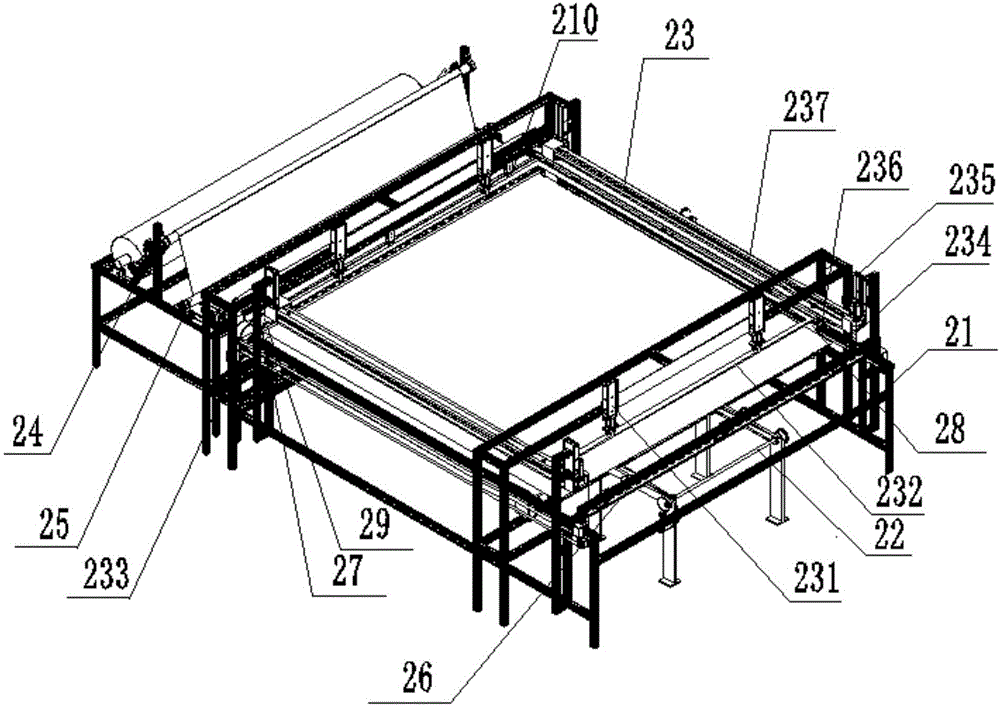

[0066] Such as figure 1 , figure 2 As shown, a fully automatic production line for right-angle bed sheets, including a pallet 1 and a trimming unit 2 placed in sequence, a first hemming unit 3, a first sewing unit 4, a second hemming unit 5, and a second sewing unit 6. The first conveying mechanism 8 and the second conveying mechanism 10;

[0067] The edge trimming unit 2 is used to trim the cloth 7 on the pallet 1, and transport the pallet 1 and the trimmed cloth 7 to the first hemming unit 3 through the first conveying mechanism 8;

[0068] The first hemming unit 3 is used for hemming the two parallel sides of the cloth 7 on the pallet 1, and transporting the pallet 1 and the cloth 7 to the first sewing unit 4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap