Line-shaped wall with modularized prefabricated thermal insulating load bearing wallboards

A modular, wallboard technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of greenhouse effect and acid rain, high energy consumption, air pollution, etc., achieve fast assembly speed, reduce on-site operations, and high degree of industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to further illustrate the present invention, the in-line wall of modular prefabricated thermal insulation load-bearing wall panels provided by the present invention and its construction method are described in detail below in conjunction with the accompanying drawings and examples, but they should not be understood as limiting the protection scope of the present invention.

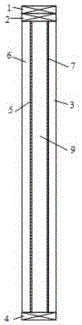

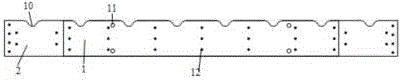

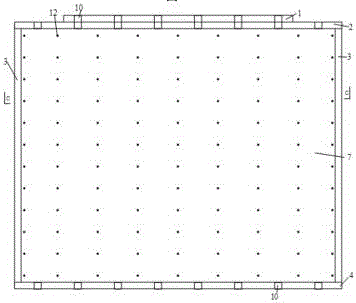

[0035] A kind of in-line wall of modularized prefabricated thermal insulation load-bearing wall panels and its construction method, such as Figure 1~Figure 11 As shown, it includes the upper roof beam board 1, the lower roof beam board 2, the side wall bone column 3, the bottom beam board 4, the interior wall panel 5, the gypsum board installation wooden strip 6, the exterior wall panel 7, and the inner filling insulation material 8 , Bone columns 9, air vents 10, hoisting holes 11, nails 12, top beam connecting plates 13, inter-board connectors 14 and anti-corrosion wood or floor panels 15....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com